Carbon thermal reduction is used to enrich alumina from fly ash and prepare ferrosilicon alloy

-

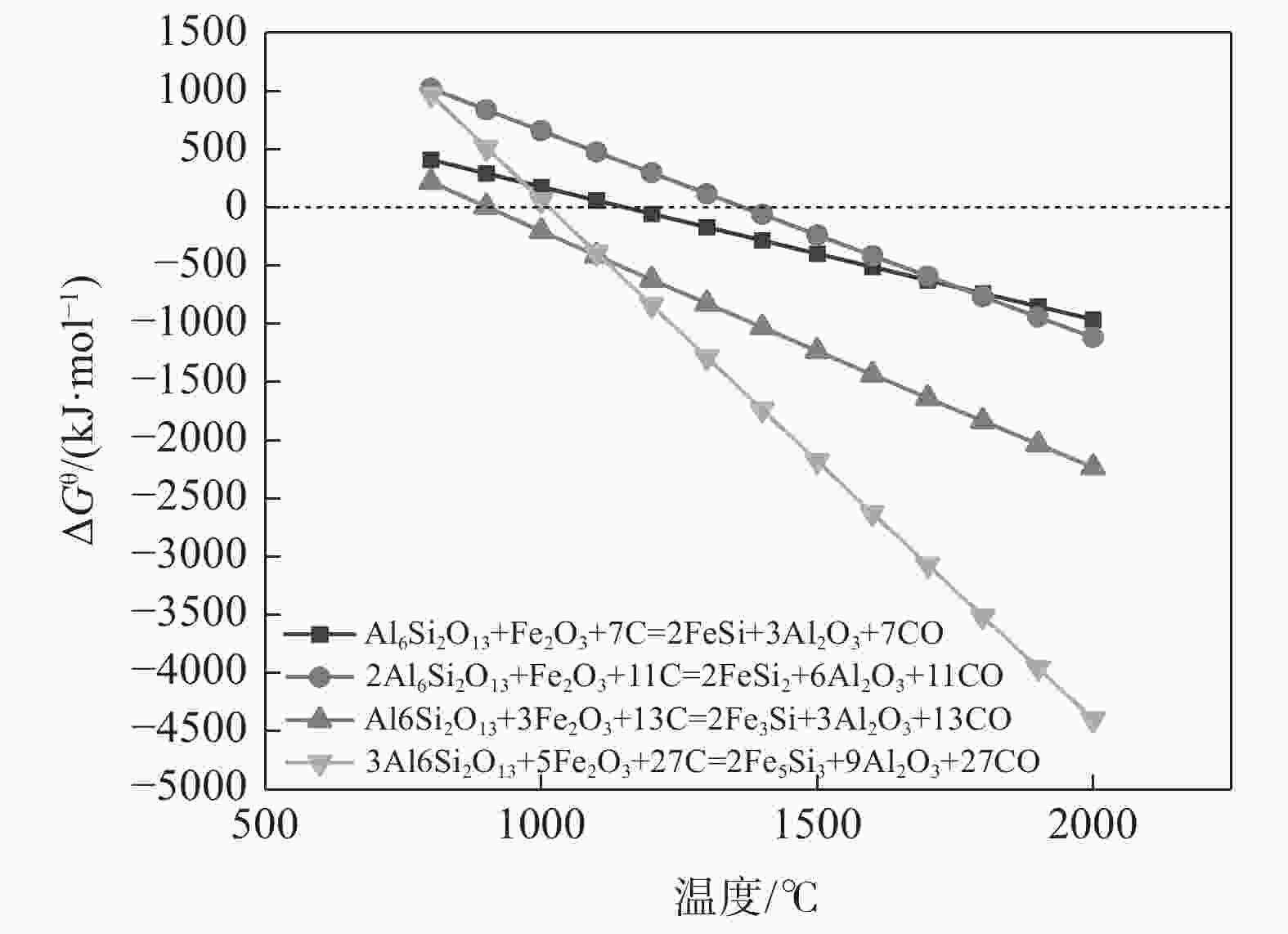

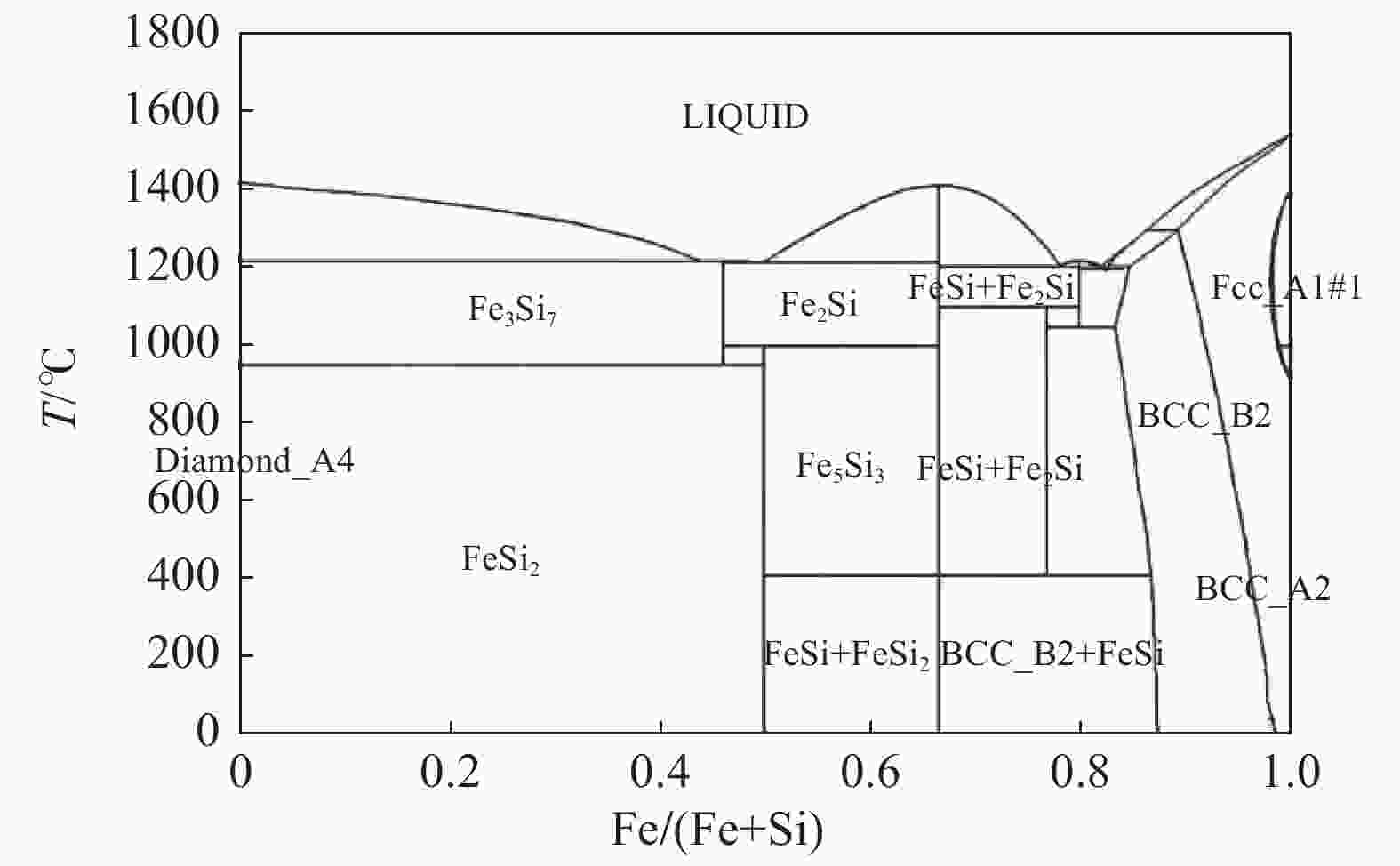

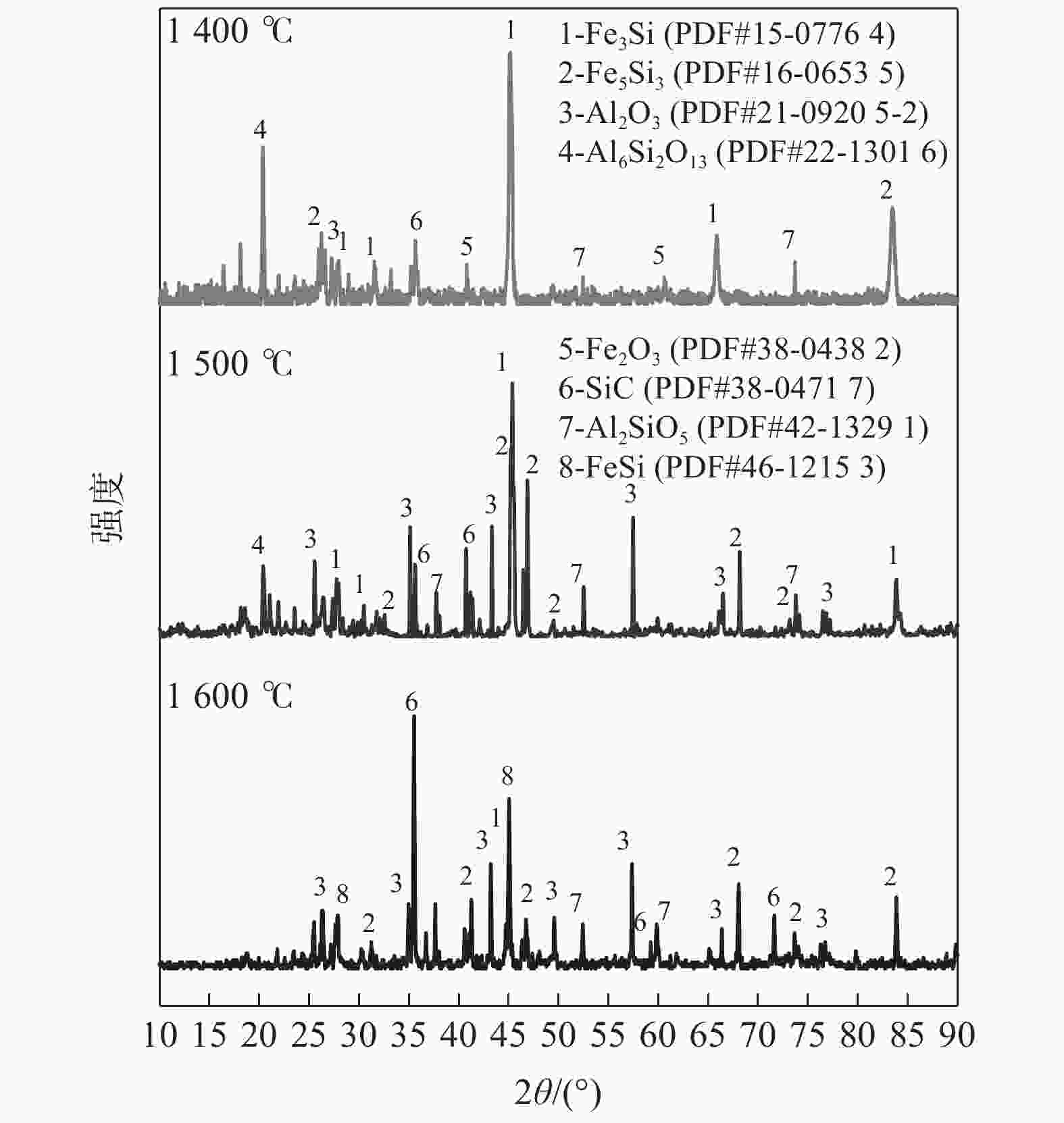

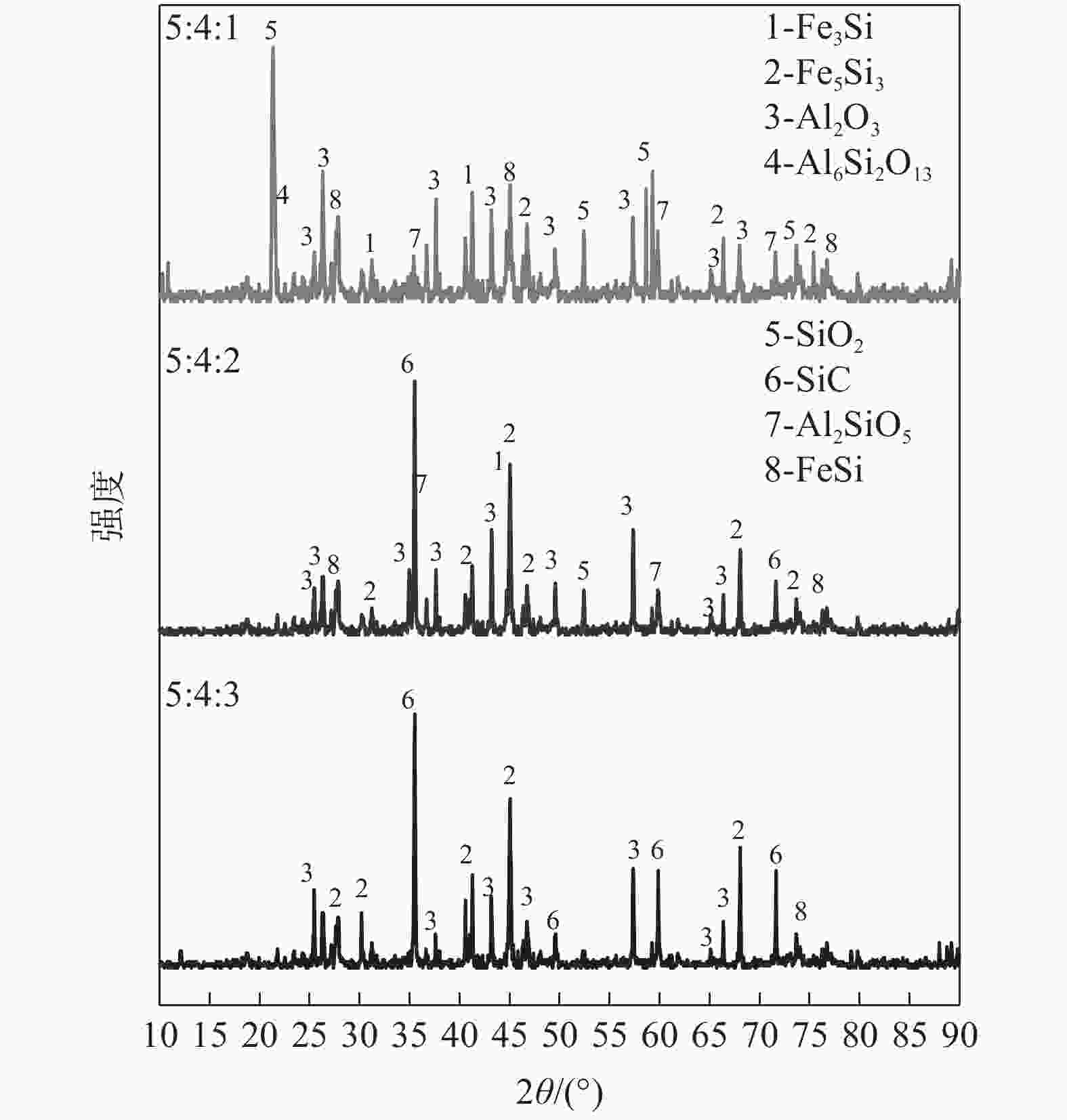

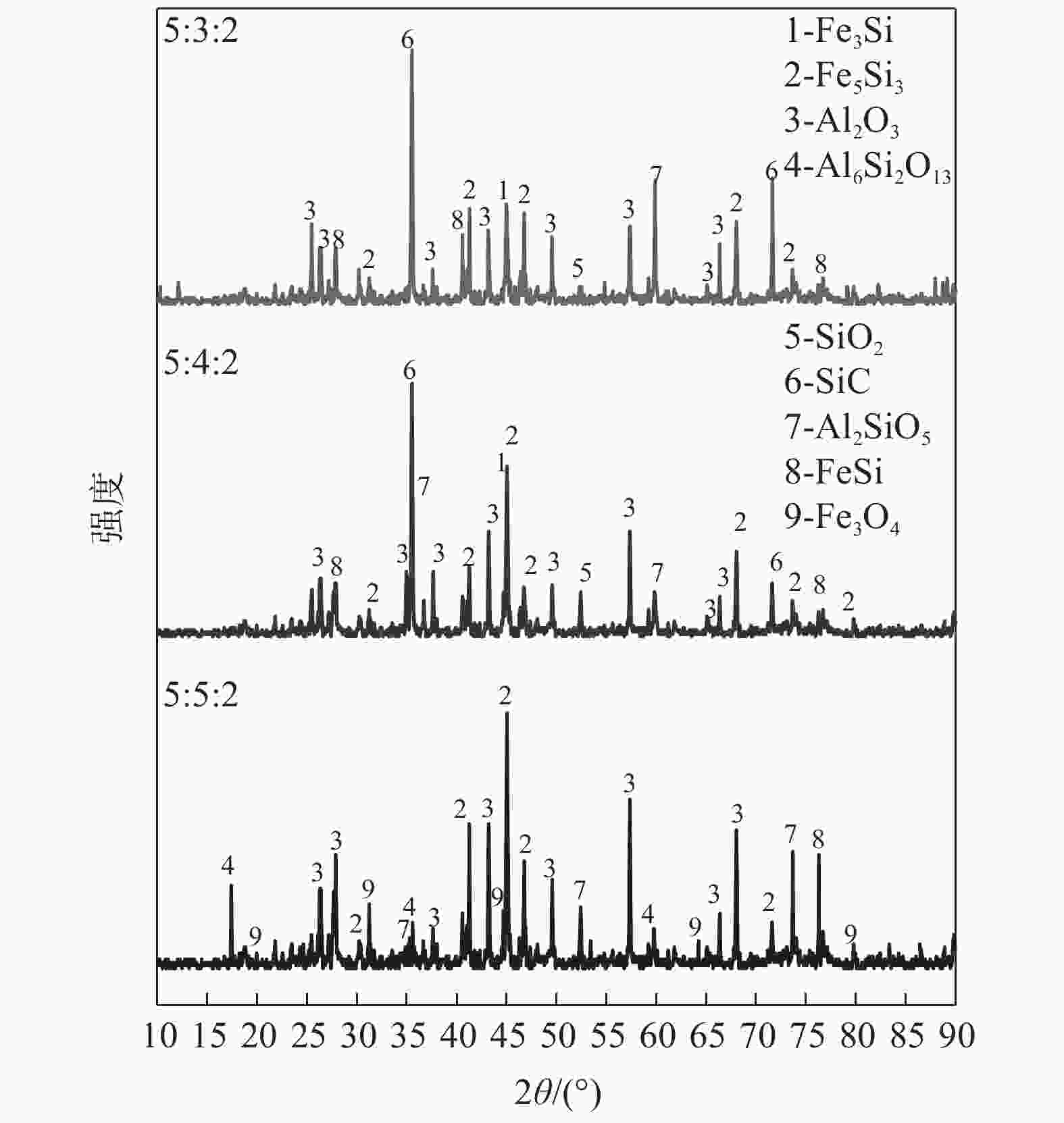

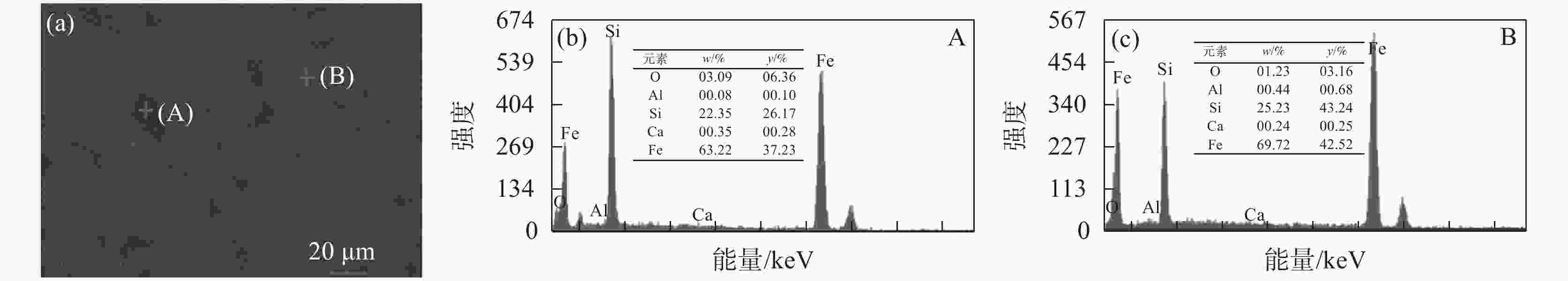

摘要: 在实验室条件下对粉煤灰进行了碳热还原制备硅铁合金并富集氧化铝试验,回收粉煤灰中的Si、Fe、Al等元素。研究发现,反应过程中,当温度升高,生成的硅铁合金中硅的含量随之升高。当配碳量增加,粉煤灰中莫来石相的Al-O-Si键更容易分解,还原成氧化铝和二氧化硅。碳热还原时加入Fe2O3不仅能够降低还原温度,而且莫来石相中的二氧化硅更易被还原成硅,并与金属铁结合生成硅铁合金,这为后续硅铁合金和氧化铝的分离创造了条件。该工艺将粉煤灰、Fe2O3和煤粉以5∶4∶2的质量比进行配料,使用电阻炉在

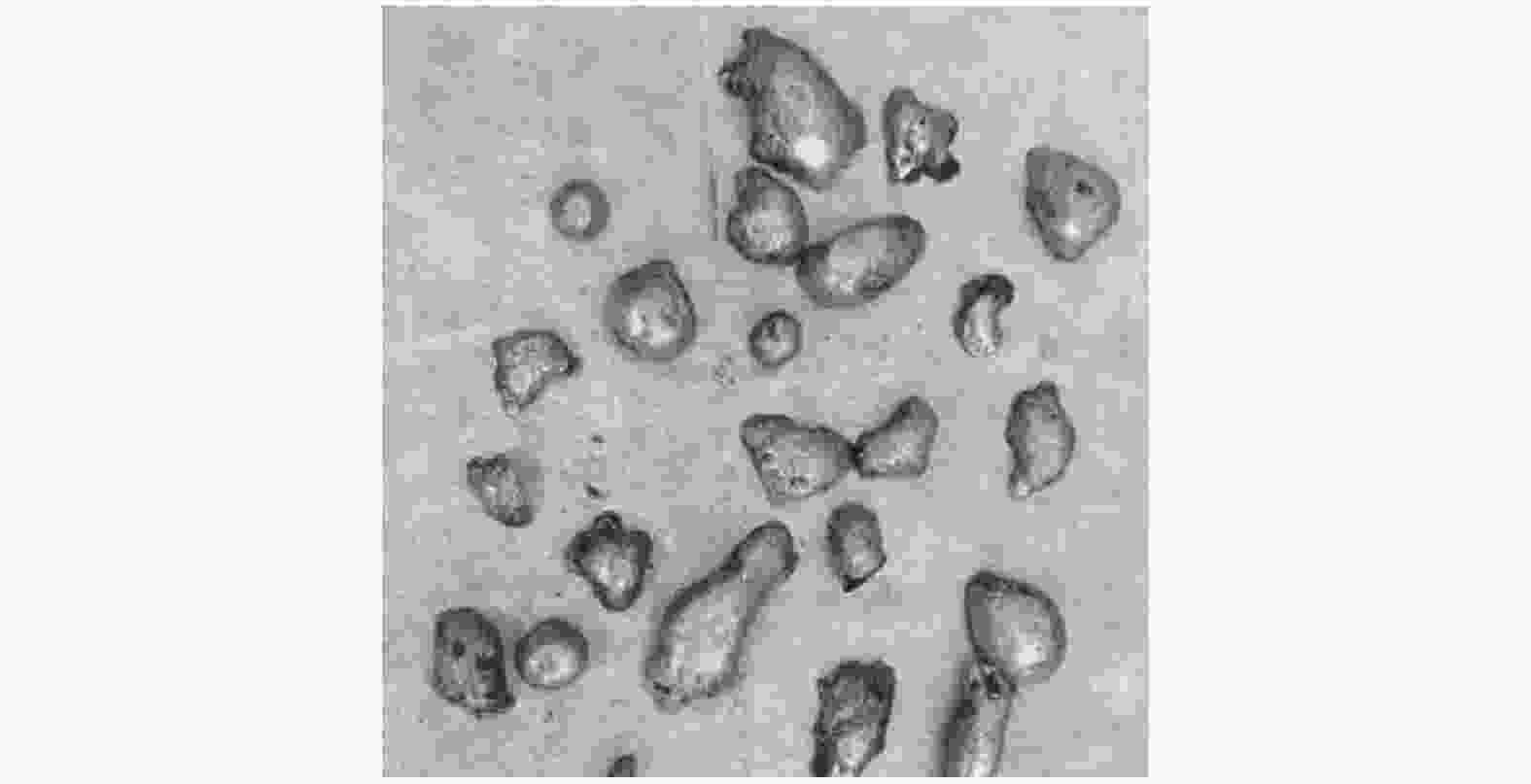

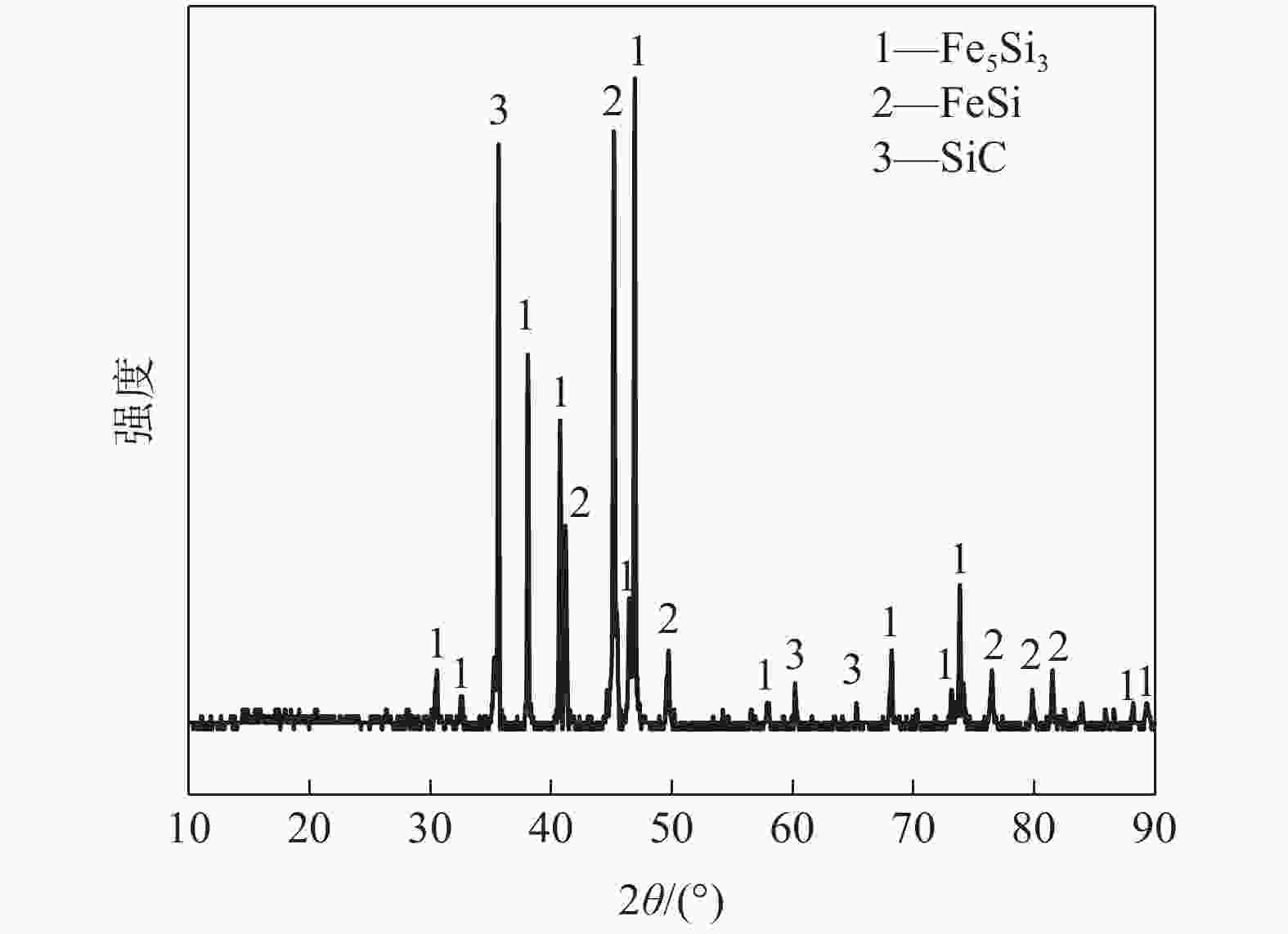

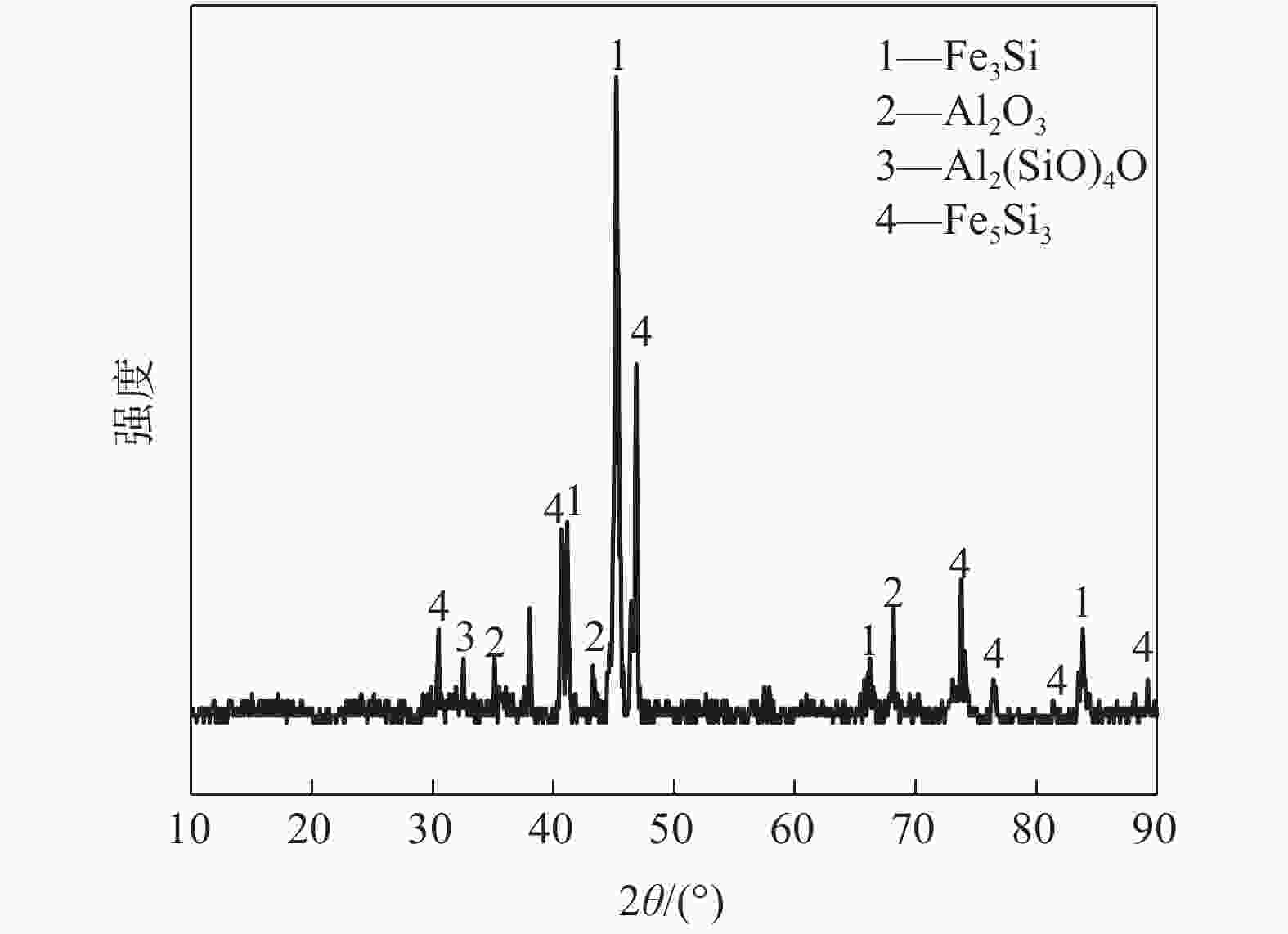

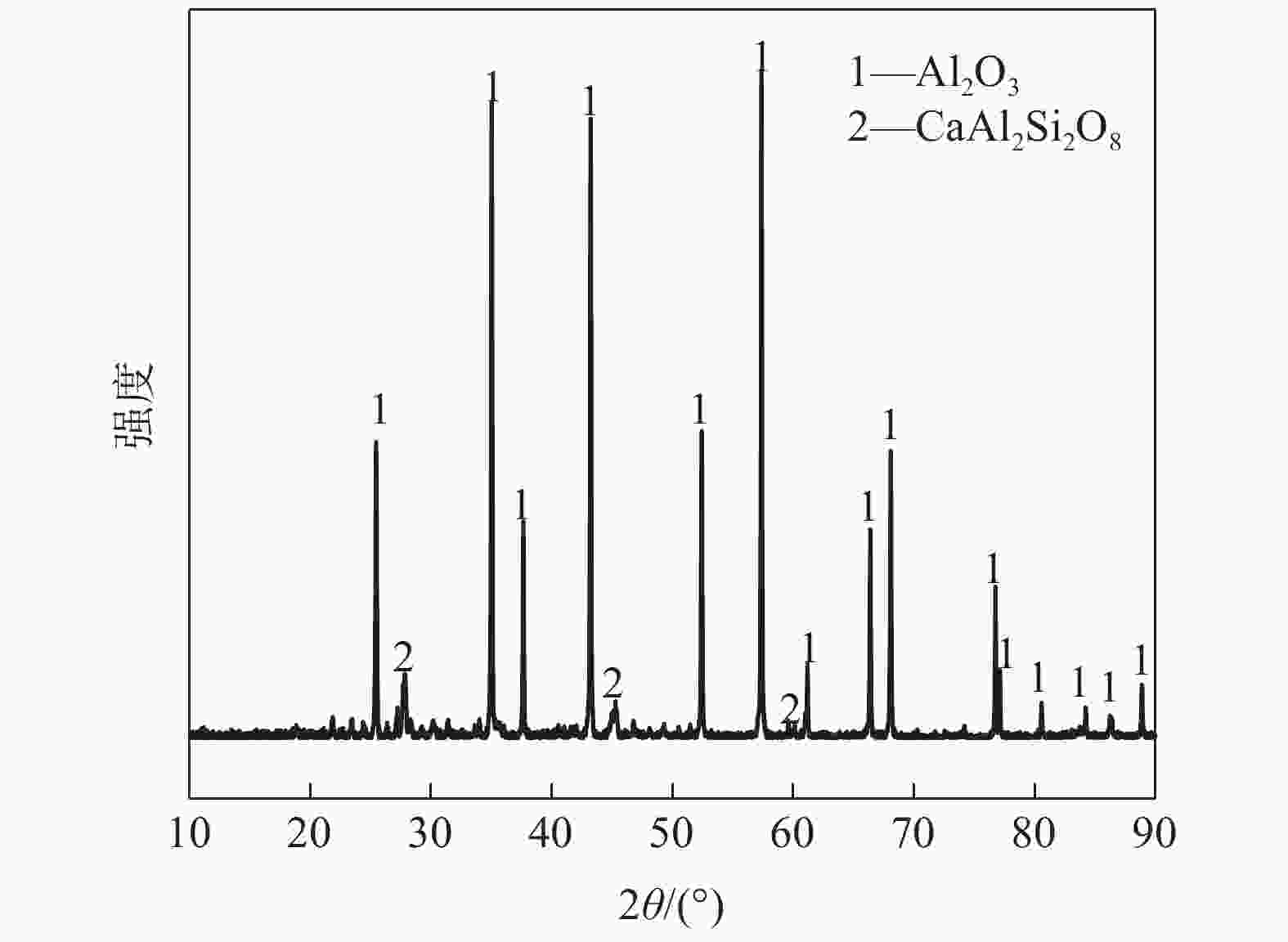

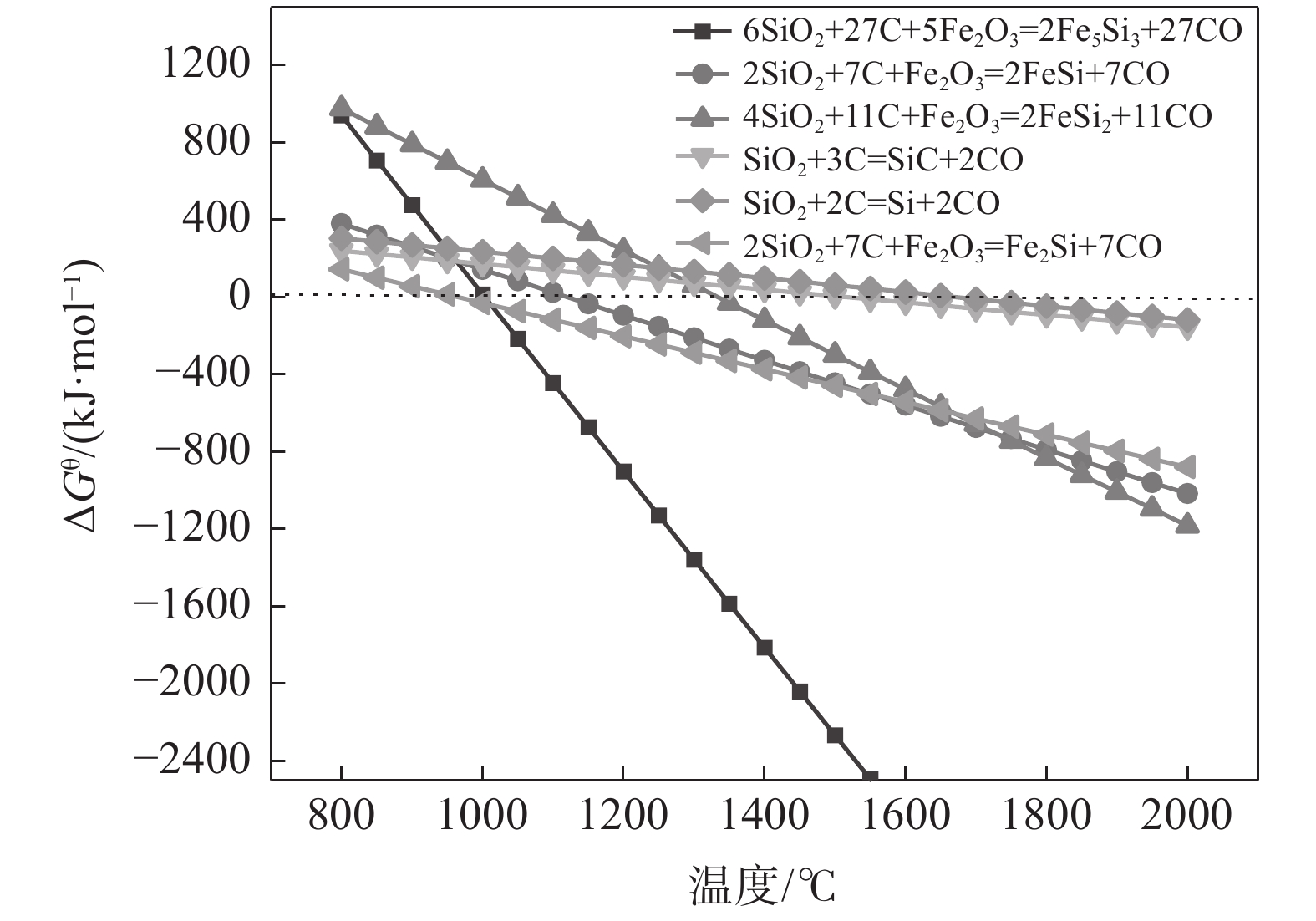

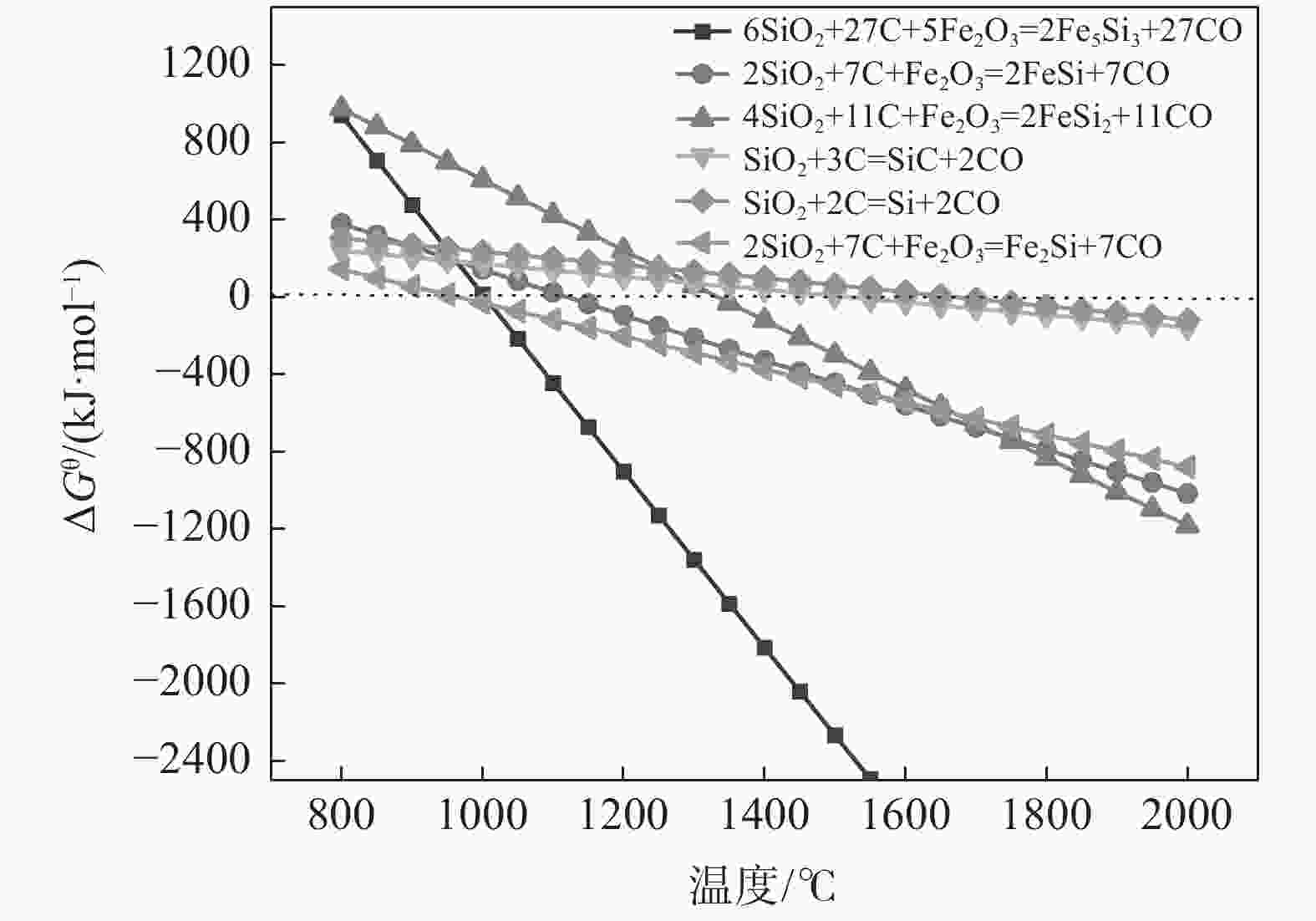

1600 ℃的条件下进行焙烧,保温2 h后随炉冷却,通过破碎、筛分、研磨、磁选处理还原后的物料,得到硅铁合金初级产品及氧化铝含量较高的尾渣,硅的回收率达到76.44%,铝的实际回收率达到93.96%。Abstract: The comprehensive utilization of fly ash is a solid waste industry with high technical content and application potential, which integrates environmental protection and resource recycling. Ferrosilicon alloy was prepared by carbothermal reduction of fly ash under laboratory conditions and alumina was enriched to recover Si, Fe, Al and other elements in fly ash. It was found that the content of silicon in the ferrosilicon alloy increased with the increase of temperature during the reaction. When the carbon content increases, the Al-O-Si bond of the mullite phase in the fly ash is more easily decomposed and reduced to alumina and silica. The carbothermal reduction is carried out under the condition of adding Fe2O3. After adding Fe2O3, not only the temperature of carbothermal reduction can be reduced, but also the silicon dioxide in mullite phase is easier to be reduced to silicon, and combined with metal iron to form ferrosilicon alloy, which creates conditions for the subsequent separation of ferrosilicon alloy and alumina. In this process, fly ash, iron oxide and pulverized coal are mixed at a mass ratio of 5∶4∶2, and roasted in a resistance furnace at 1 600 °C. After holding for two hours, they are cooled with the furnace. After crushing, screening, grinding and magnetic separation, the reduced materials are treated to obtain ferrosilicon alloy primary products and tailings with high alumina content. The desilication rate reaches 76.44%, and the recovery rate of aluminum reaches 93.96%.-

Key words:

- ferrosilicon /

- aluminum oxid /

- coal fly ash /

- carbon thermal reduction /

- magnetic selection

-

表 1 粉煤灰样品的主要化学组成

Table 1. Main chemical composition of fly ash samples %

SiO2 Al2O3 TFe CaO K2O NaO MgO TiO2 P S MnO 61.85 18.35 4.75 3.37 2.58 1.42 1.60 0.80 0.10 0.34 0.07 表 2 硅铁合金颗粒成分

Table 2. Particle composition of ferrosilicon alloy

% Fe Si O Al Ca K Na Mg 63.400 20.910 3.647 0.424 1.342 1.540 0.573 0.637 表 3 硅铁合金粉末成分

Table 3. Composition of ferrosilicon alloy powder

% Fe Si O Ca Al K Mg Na 53.53 32.53 4.48 2.18 1.15 1.70 0.81 0.59 表 4 非磁性部分成分

Table 4. Composition of non-magnetic fraction

% Al O Si Ca K Mg Na 其他 35.12 45.85 2.79 4.67 2.69 1.29 1.15 6.44 -

[1] Lu Ying. The comprehensive utilization and development prospects of fly ash[J]. Heilongjiang Science and Technology Information, 2012(11):38. (卢英. 粉煤灰的综合利用与发展前景[J]. 黑龙江科技信息, 2012(11):38.Lu Ying. The comprehensive utilization and development prospects of fly ash[J]. Heilongjiang Science and Technology Information, 2012(11): 38. [2] Wang Di, Qiao Liang, Gong Hao, et al. The current research status of comprehensive utilization of fly ash resources[J]. Modern Mining, 2021,37(5):18-20. (王迪, 乔亮, 龚浩, 等. 粉煤灰资源化综合利用研究现状[J]. 现代矿业, 2021,37(5):18-20. doi: 10.3969/j.issn.1674-6082.2021.05.005Wang Di, Qiao Liang, Gong Hao, et al. The current research status of comprehensive utilization of fly ash resources[J]. Modern Mining, 2021, 37(5): 18-20. doi: 10.3969/j.issn.1674-6082.2021.05.005 [3] Chang Ge, Xing Tai. Fly ash is not garbage, it is a misplaced resource[N]. CPPCC Daily, 2019-11-05(003). (常歌, 邢泰. 粉煤灰不是垃圾, 是放错地方的资源[N]. 人民政协报, 2019-11-05(003).Chang Ge, Xing Tai. Fly ash is not garbage, it is a misplaced resource[N]. CPPCC Daily, 2019-11-05(003). [4] Bhangare R C, Tiwari M, Ajmal P Y, et al. Distribution of natural radioactivity in coal and combustion residues of thermal power plants[J]. J. Radioanal. Nucl. Chem., 2014,300:17-22. doi: 10.1007/s10967-014-2942-3 [5] Cui Jiaxin, Wang Lianyong, He Yan, et al. Hazards of fly ash and its utilization[J]. Comprehensive Utilization of Resources in China, 2022,40(3):118-121. (崔家新, 王连勇, 何艳, 等. 粉煤灰的危害及其利用现状[J]. 中国资源综合利用, 2022,40(3):118-121. doi: 10.3969/j.issn.1008-9500.2022.03.034Cui Jiaxin, Wang Lianyong, He Yan, et al. Hazards of fly ash and its utilization[J]. Comprehensive Utilization of Resources in China, 2022, 40(3): 118-121. doi: 10.3969/j.issn.1008-9500.2022.03.034 [6] Lei Xuefei, Qi Guangxia, Sun Yinglong, et al. Removal of uranium and gross radioactivity from coal bottom ash by CaCl2 roasting followed by HNO3 leaching[J]. J. Hazard. Mater., 2014,276:346-352. doi: 10.1016/j.jhazmat.2014.05.052 [7] Somerset V S, Petrik L F, White R A, et al. The use of X-ray fluorescence (XRF) analysis in predicting the alkaline hydrothermal conversion of fly ash precipitates into zeolites[J]. Talanta., 2004,64:109-114. doi: 10.1016/j.talanta.2003.10.059 [8] Zhang Zhaoyang, Lei Minjun, Huang Kai, et al. Research on the preparation of ferrosilicon alloys by fly ash carbon thermal reduction method[J]. Ferroalloys, 2021,52(5):21-24. (张照阳, 雷敏军, 黄凯, 等. 粉煤灰碳热还原法制备硅铁合金工艺研究[J]. 铁合金, 2021,52(5):21-24.Zhang Zhaoyang, Lei Minjun, Huang Kai, et al. Research on the preparation of ferrosilicon alloys by fly ash carbon thermal reduction method[J]. Ferroalloys, 2021, 52(5): 21-24. [9] Chernenkov Y P, Ershov N V, Lukshina V A, et al. An X-ray diffraction study of the short-range ordering in the soft-magnetic Fe-Si alloys with induced magnetic anisotropy[J]. Physica B., 2007,396:220-230. doi: 10.1016/j.physb.2007.04.008 [10] Liu Chenjia, Zhao Aichun, Li Xu, et al. Research development on extracting alumina from fly ash[J]. China Nonferrous Metallurgy, 2023, 52(1): 75-83. ) (刘宸嘉, 赵爱春, 李旭, 等. 粉煤灰提取氧化铝研究进展[J]. 中国有色冶金, 2023, 52(1): 75-83.Liu Chenjia, Zhao Aichun, Li Xu, et al. Research development on extracting alumina from fly ash[J]. China Nonferrous Metallurgy, 2023, 52(1): 75-83. ) [11] Zhu Keming, Zhang Xinyuan, Wang Le, et al. Research progress on alumina extraction process by fly ash alkali method[J]. Light Metal, 2019(9):4-8. (朱科明, 张馨圆, 王乐, 等. 粉煤灰碱法提取氧化铝工艺研究进展[J]. 轻金属, 2019(9):4-8.Zhu Keming, Zhang Xinyuan, Wang Le, et al. Research progress on alumina extraction process by fly ash alkali method[J]. Light Metal, 2019(9): 4-8. [12] Wu Yan. Study on extraction of alumina and silica from fly ash[D]. Shenyang: Northeastern University, 2008. (吴艳. 从粉煤灰中提取氧化铝和二氧化硅的研究[D]. 沈阳: 东北大学, 2008.Wu Yan. Study on extraction of alumina and silica from fly ash[D]. Shenyang: Northeastern University, 2008. [13] Yang Jing, Jiang Zhouqing, Ma Hongwen, et al. The bauxite resource in China and advances in the techniques of extracting alumina from high-alumina coal fly ash[J]. Earth Science Frontiers, 2014, 21(5):313-324. (杨静, 蒋周青, 马鸿文, 等. 中国铝资源与高铝粉煤灰提取氧化铝研究进展[J]. 地学前缘, 2014, 21(5):313-324.Yang Jing, Jiang Zhouqing, Ma Hongwen, et al. The bauxite resource in China and advances in the techniques of extracting alumina from high-alumina coal fly ash[J]. Earth Science Frontiers, 2014, 21(5): 313-324. [14] Wang Weijiang, Zhang Yongfeng. Technique status and progress of alumina extraction from coal fly ash[J]. Nonferrous Metals Engineering, 2021,11(10):79-91,122. (王卫江, 张永锋. 从粉煤灰提取氧化铝的技术现状及工艺进展[J]. 有色金属工程, 2021,11(10):79-91,122.Wang Weijiang, Zhang Yongfeng. Technique status and progress of alumina extraction from coal fly ash[J]. Nonferrous Metals Engineering, 2021, 11(10): 79-91,122. [15] Hou Huiyao, Chen Yongqiang, Ma Baozhong, et al. Research status and progress of alumina recovery from fly ash[J]. Mining and Metallurgy, 2021, 30(3):30-39. (侯慧耀, 陈永强, 马保中, 等. 粉煤灰回收氧化铝工艺研究现状及进展[J]. 矿冶, 2021, 30(3):30-39.Hou Huiyao, Chen Yongqiang, Ma Baozhong, et al. Research status and progress of alumina recovery from fly ash[J]. Mining and Metallurgy, 2021, 30(3): 30-39. [16] Liu Xiaoting, Wang Baodong, Xiao Yongfeng, et al. Pre-desilication process of alumina-rich fly ash in alkali solution[J]. China Powder Technology, 2013,19(6):24-27. (刘晓婷, 王宝冬, 肖永丰, 等. 高铝粉煤灰碱溶预脱硅过程研究[J]. 中国粉体技术, 2013,19(6):24-27.Liu Xiaoting, Wang Baodong, Xiao Yongfeng, et al. Pre-desilication process of alumina-rich fly ash in alkali solution[J]. China Powder Technology, 2013, 19(6): 24-27. [17] Sun Zhenhua, Bao Weijun, Li Huiquan, et al. Mineral phase change of high-alumina fly ash during desilication and extraction of Al2O3 by alkali dissolution process[J]. Chinese Journal of Process Engineering, 2013,13(3):403-408. (孙振华, 包炜军, 李会泉, 等. 高铝粉煤灰预脱硅碱溶提铝过程中的物相转变规律[J]. 过程工程学报, 2013,13(3):403-408.Sun Zhenhua, Bao Weijun, Li Huiquan, et al. Mineral phase change of high-alumina fly ash during desilication and extraction of Al2O3 by alkali dissolution process[J]. Chinese Journal of Process Engineering, 2013, 13(3): 403-408. [18] Lan Weixing. Research on the process of extracting aluminum slag from fly ash in Huainan to prepare silica[D]. Huainan: Anhui University of Science and Technology, 2012. (兰伟兴. 淮南粉煤灰提铝渣制备白炭黑的工艺研究[D]. 淮南: 安徽理工大学, 2012.Lan Weixing. Research on the process of extracting aluminum slag from fly ash in Huainan to prepare silica[D]. Huainan: Anhui University of Science and Technology, 2012. [19] Ma Zhao. Extraction of alumina and silica from fly ash in ash field[D]. Huainan: Anhui University of Science and Technology, 2015. (马钊. 灰场粉煤灰提取氧化铝和白炭黑[D]. 淮南: 安徽理工大学, 2015.Ma Zhao. Extraction of alumina and silica from fly ash in ash field[D]. Huainan: Anhui University of Science and Technology, 2015. [20] Li Xiaoguang, Ding Shuqiang, Zhuo Jinde, et al. Fly ash silica extraction technology and industrial development status[J]. Inorganic Chemicals Industry, 2018,50(12):1-4. (李晓光, 丁书强, 卓锦德, 等. 粉煤灰提取二氧化硅技术及工业化发展现状[J]. 无机盐工业, 2018,50(12):1-4.Li Xiaoguang, Ding Shuqiang, Zhuo Jinde, et al. Fly ash silica extraction technology and industrial development status[J]. Inorganic Chemicals Industry, 2018, 50(12): 1-4. [21] Xue Yang. Study on the preparation of ferrosilicon alloys and enrichment of alumina by carbon thermal reduction of fly ash[D]. Chongqing: Chongqing University, 2020. (薛阳. 粉煤灰碳热还原制备硅铁合金并富集氧化铝的研究[D]. 重庆: 重庆大学, 2020.Xue Yang. Study on the preparation of ferrosilicon alloys and enrichment of alumina by carbon thermal reduction of fly ash[D]. Chongqing: Chongqing University, 2020. [22] Yu Wenzhou, Li Jie, You Zhixiong, et al. Study on the preparation of ferrosilicon alloys by carbon thermal reduction of fly ash[C]//Chinese Society for Metals, Proceedings of the 11th China Iron and Steel Annual Conference—S02. Steelmaking and Continuous Casting. Beijing: Metallurgical Industry Press, 2017. -

下载:

下载: