Effect of steel slag ratio on the sintering of vanadium-titanium magnetite ore

-

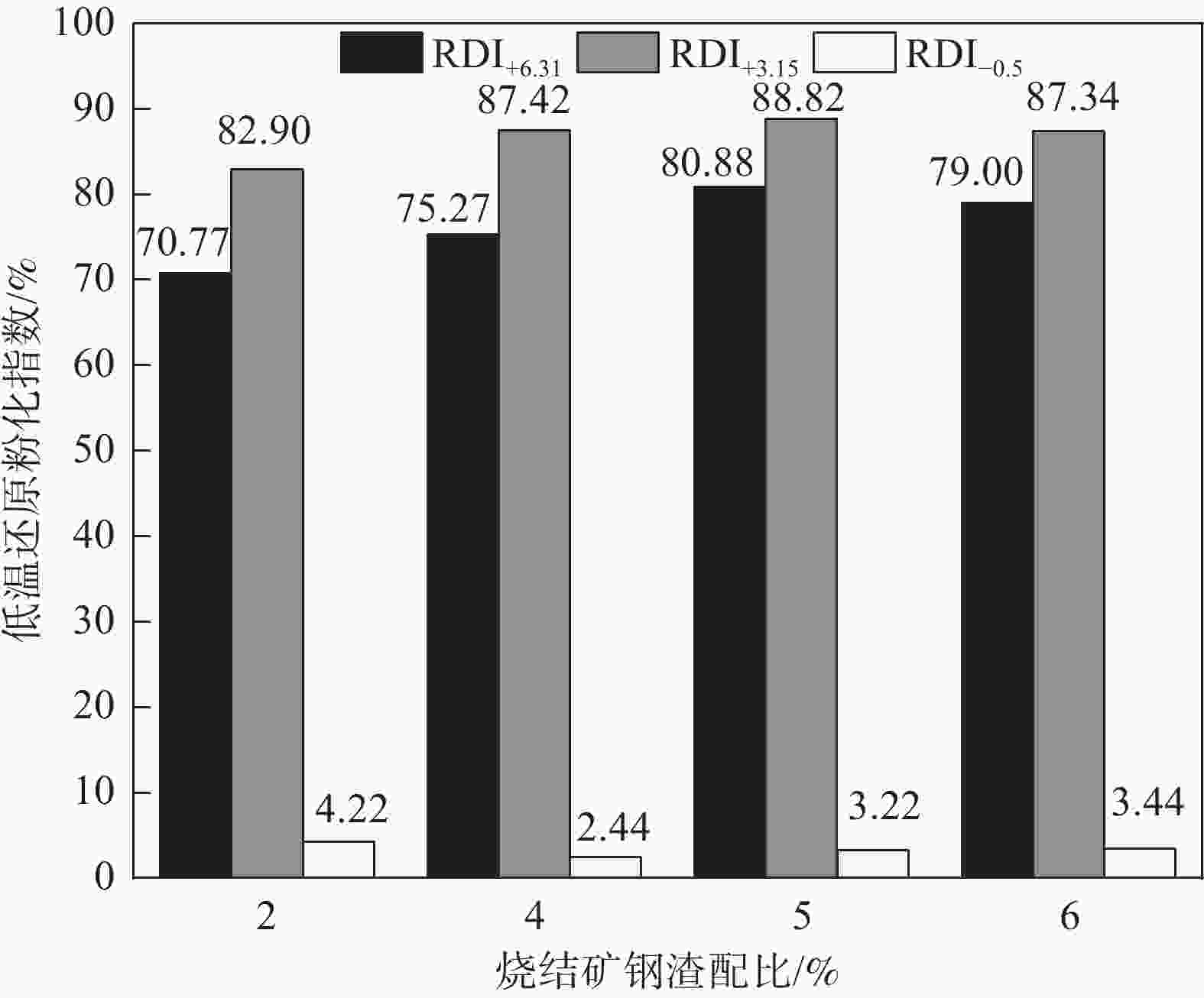

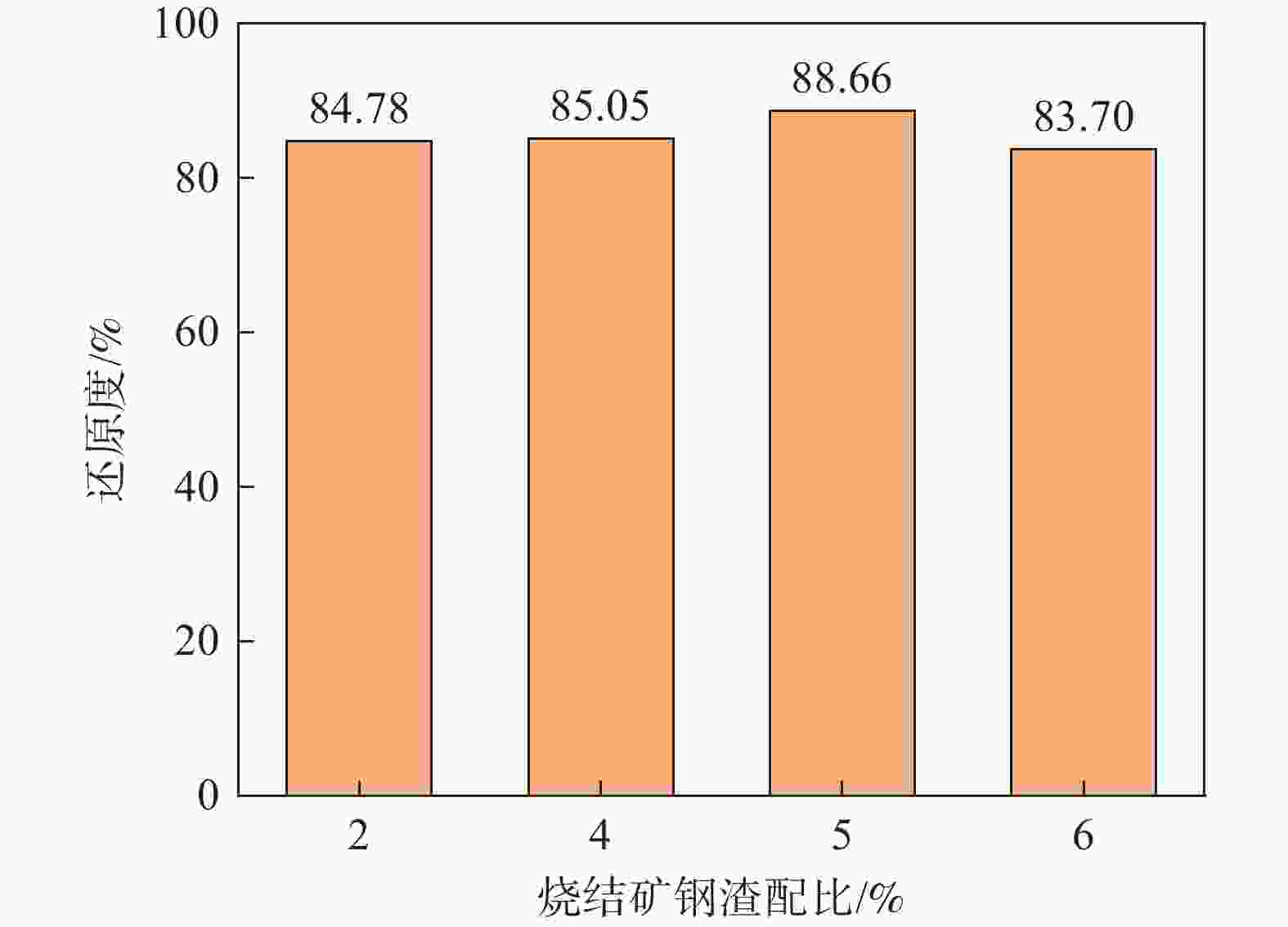

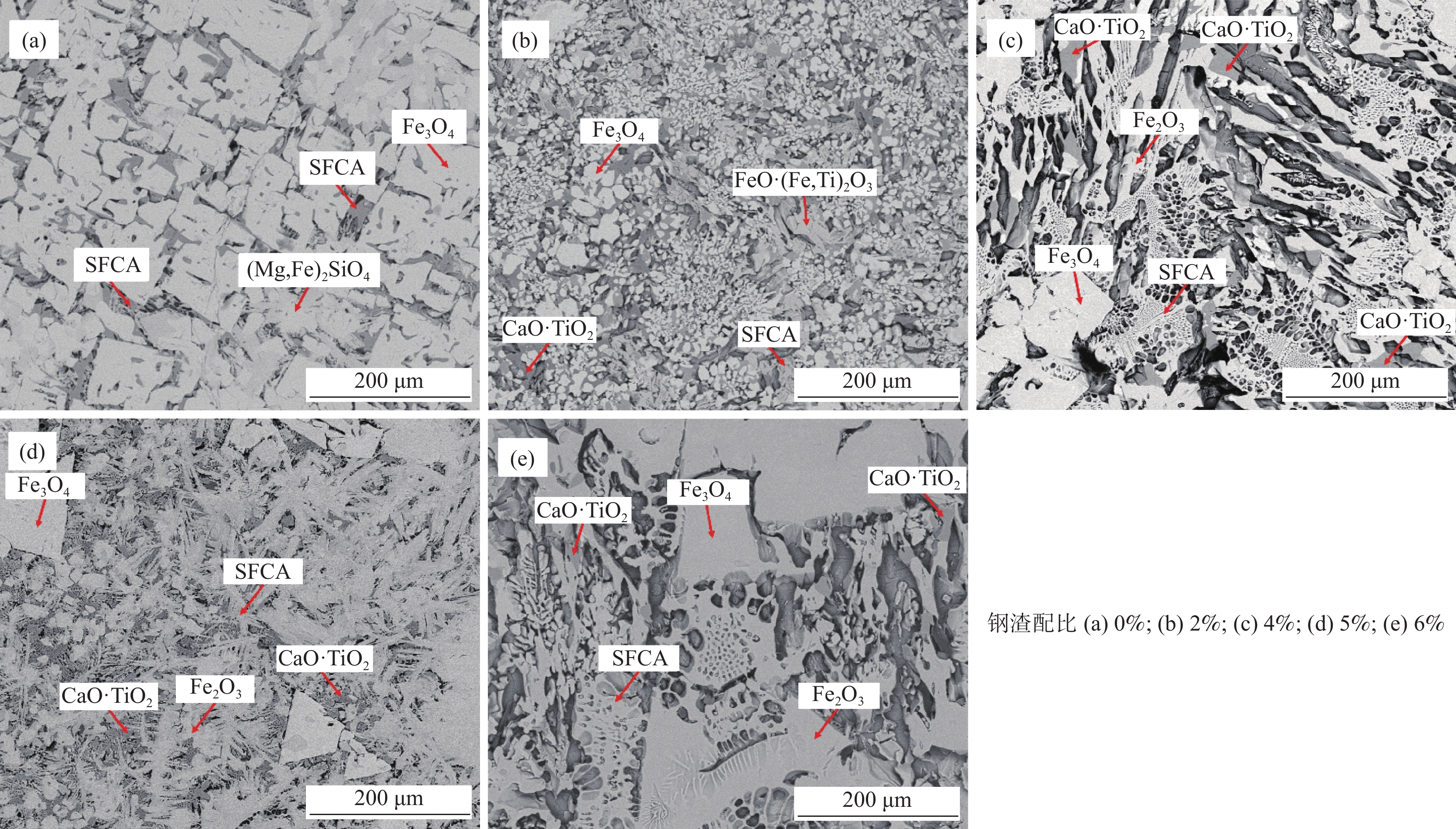

摘要: 为优化钢渣的循环利用策略,提升钢铁企业的经济效益与社会效益,首先分析了钢渣中钛元素与磷元素的含量,并基于不同钢渣配比进行烧结杯试验。基于系统研究可知,在钒钛磁铁矿烧结过程中,随钢渣配比增大,烧结矿中钙钛矿相增加,部分粘结相由复合铁酸钙相向钙钛矿相转变,烧结矿整体矿相呈现不均匀化,复杂性增强,该矿相转变对烧结矿强度造成不利影响。基于磷元素富集效应,随钢渣配比增大,成品烧结矿中磷元素含量升高,当钢渣配加量为5%时,烧结杯试验烧损率最低为15.42%。钢渣配比为4%时,烧结矿成品率最高为86.49%,随钢渣配比继续增大成品率基本保持稳定。Abstract: To optimize the recycling strategy of steel slag and enhance the economic and social benefits of steel companies, the study first analyzed the content of titanium and phosphorus elements in steel slag and conducted sintering pot tests based on different steel slag ratios. In the vanadium-titanium magnetite sintering process, with the increase of steel slag ratio, the perovskite phase in sinter increases, and bonding phases transform from SFCA to perovskite phases. This transformation leads to an uneven mineral phase in sinter and increases its complexity, which has a detrimental effect on the strength of the sintered ore. Additionally, with the increase of steel slag ratio, the phosphorus content in the finished sintered ore also increases. When the steel slag addition amount reaches 5%, the lowest sintering loss rate in the sintering pot test is 15.42%. At a steel slag ratio of 4%, the maximum yield of sintered ore is 86.49%, as the ratio continues to increase, the yield remains relatively stable.

-

Key words:

- sintering /

- steel slag /

- ratio /

- metallurgical properties /

- microstructure

-

表 1 原燃料化学成分分析

Table 1. Chemical compositions of raw materials and fuels analysis

% 种类 TFe FeO SiO2 CaO Al2O3 MgO MnO TiO2 P2O5 V 烧损 矿粉1 64.45 28.71 3.31 0.60 0.82 0.76 0.06 3.26 0.09 0.30 −2.46 矿粉2 66.64 26.56 6.15 0.25 0.29 0.39 0.09 0.06 0.02 0.01 −2.01 矿粉3 66.11 28.81 5.96 0.85 1.02 0.62 0.11 2.23 0.04 0.27 −2.45 矿粉4 60.77 4.58 3.94 0.10 2.63 0.08 0.11 0.12 0.30 0.01 6.13 矿粉5 60.27 28.71 7.62 4.08 2.45 0.82 0.22 0.66 0.18 0.03 4.61 高炉返矿 54.57 8.99 5.30 10.02 2.22 2.23 0.23 1.70 0.13 0.13 −0.70 杂料 44.15 19.08 7.66 10.67 3.02 2.22 1.59 5.22 0.31 0.39 7.65 钢渣 20.65 19.34 10.45 36.11 2.75 14.38 0.84 1.24 2.81 0.60 −0.60 熔剂1 0.00 0.00 0.44 68.62 0.98 6.69 0.00 0.09 0.06 0.00 22.32 熔剂2 0.00 0.00 2.07 44.26 0.42 32.76 0.00 0.04 0.02 0.00 19.63 燃料1 0.00 0.00 5.13 2.88 2.04 0.19 0.04 0.12 0.06 0.00 85.93 燃料2 0.00 0.00 17.11 2.26 7.61 0.80 0.22 0.44 0.19 0.05 65.57 表 2 烧结杯试验方案

Table 2. Experimental protocol for sintering pot tests

% 试验方案 矿粉1 矿粉2 矿粉3 矿粉4 矿粉5 高炉返矿 杂料 外配返矿 钢渣配比 熔剂1 熔剂2 燃料1 燃料2 1 36.65 7.75 5.45 11.00 14.00 3.00 5.50 0.00 0.00 9.75 1.40 2.75 2.75 2 33.00 9.00 5.00 9.80 9.30 2.75 5.00 9.10 2.00 9.85 0.20 2.50 2.50 3 34.00 8.25 5.00 9.00 8.60 2.75 5.00 9.10 4.00 9.30 0.00 2.50 2.50 4 39.95 2.90 4.80 9.00 8.00 2.75 5.00 9.10 5.00 8.50 0.00 2.50 2.50 5 41.95 1.80 3.35 9.00 8.00 2.75 5.00 9.10 6.00 8.05 0.00 2.50 2.50 表 3 不同钢渣配比条件下烧结矿化学成分

Table 3. Chemical compositions of sinter under different steel slag ratios

试验方案 w/% R TFe SiO2 CaO Al2O3 MgO MnO TiO2 S P2O5 V 1 55.02 4.47 9.78 1.69 2.16 0.26 1.86 0.06 0.16 0.24 2.19 2 56.12 4.52 9.79 1.88 2.00 0.23 1.72 0.06 0.17 0.19 2.17 3 55.57 4.60 9.51 1.84 1.96 0.24 1.68 0.04 0.19 0.21 2.06 4 55.02 4.63 9.72 1.66 2.13 0.24 1.85 0.05 0.22 0.22 2.10 5 55.45 4.64 9.93 1.76 2.36 0.30 1.84 0.06 0.26 0.24 2.14 表 4 烧结矿样品XRD定量分析结果

Table 4. XRD quantitative analysis results for sinter samples

% 物相 方案1 方案2 方案3 方案4 方案5 Fe2O3 25.42 21.64 31.37 23.62 23.56 Fe3O4 28.15 24.37 23.45 24.63 24.20 SFCA 43.09 49.58 41.58 46.48 45.02 Fe2TiO4 0.25 0.51 0.86 1.63 1.79 CaTiO3 2.14 2.04 1.78 1.73 3.64 V2O3 0.94 1.87 0.96 1.91 1.80 -

[1] Qian Qiang. Experimental study on slag modification of converter steel slag in sinter pot[J]. Sintering and Pelletizing, 2019,44(4):67-69. (钱强. 转炉钢渣烧结杯调渣改性试验研究[J]. 烧结球团, 2019,44(4):67-69.Qian Qiang. Experimental study on slag modification of converter steel slag in sinter pot[J]. Sintering and Pelletizing, 2019, 44(4): 67-69. [2] Wang Wenshan, Ren Gang, Sun Yanqin, et al. Effect of the carbon content on mineral compositions and mineral phase microscopy of vanadium-titanium sinter in Chenggang[J]. Iron and Steel, 2010 (10): 13-17. (王文山, 任刚, 孙艳芹, 等. 配碳量对承钢钒钛烧结矿矿物组成及显微结构的影响[J]. 钢铁, 2010 (10): 13-17.Wang Wenshan, Ren Gang, Sun Yanqin, et al. Effect of the carbon content on mineral compositions and mineral phase microscopy of vanadium-titanium sinter in Chenggang[J]. Iron and Steel, 2010 (10): 13-17. [3] Xie Yu, Ye Guohua, Zuo Qi, et al. New technology of vanadium extraction from vanadium-bearing steel slag[J]. Iron Steel Vanadium Titanium, 2019, 40(1): 69-77. (谢禹, 叶国华, 左琪,等. 含钒钢渣提钒新工艺研究[J]. 钢铁钒钛, 2019, 40(1): 69-77.Xie Yu, Ye Guohua, Zuo Qi, et al. New technology of vanadium extraction from vanadium-bearing steel slag[J]. Iron Steel Vanadium Titanium, 2019, 40(1): 69-77. [4] Wei Qun, Ma Xiaolan, Zhang Haimin, et al. Production practice of sinter operation blendingwith steel slag in Anyang steel[J]. Henan Metallurgy, 2011, 19(3): 32-34. (魏群, 马小兰, 张海民, 等. 安钢烧结配用钢渣的生产实践 [J]. 河南冶金, 2011, 19(3): 32-34.Wei Qun, Ma Xiaolan, Zhang Haimin, et al. Production practice of sinter operation blendingwith steel slag in Anyang steel[J]. Henan Metallurgy, 2011, 19(3): 32-34. [5] Cheng Zhengming, An Gang, Dai Feng, et al. Study on Shougang Jingtang sintering flux structure optimization and its application[J]. Sintering and Pelletizing, 2016, 41(4): 15-19. (程峥明, 安钢, 戴峰,等. 首钢京唐烧结熔剂结构优化研究及应用[J]. 烧结球团, 2016, 41(4): 15-19.Cheng Zhengming, An Gang, Dai Feng, et al. Study on Shougang Jingtang sintering flux structure optimization and its application[J]. Sintering and Pelletizing, 2016, 41(4): 15-19. [6] Han Fengguang, Qiu Haiyu, Nie Huiyuan, et al. Experiment of proportioning bos in sintering production in meishan I & S Co[J]. Sintering and Pelletizing, 2006, 31(5): 15-18. (韩凤光, 邱海雨, 聂慧远, 等. 梅山烧结配加转炉钢渣的试验研究[J]. 烧结球团, 2006, 31(5): 15-18.Han Fengguang, Qiu Haiyu, Nie Huiyuan, et al. Experiment of proportioning bos in sintering production in meishan I & S Co[J]. Sintering and Pelletizing, 2006, 31(5): 15-18. [7] O’Connor James, Nguyen Thi Bang Tuyen, Honeyands Tom, et al. Production, characterisation, utilisation, and beneficial soil application of steel slag: A review[J]. Journal of Hazardous Materials, 2021,419:126478. doi: 10.1016/j.jhazmat.2021.126478 [8] Liu Zhengjian, Niu Lele, Zhang Jianliang, et al. Status quo and trend of technology and equipment optimization for sintering granulation in iron and steel enterprises[J]. lron and Steel, 2021, 56(10): 28-35. (刘征建, 牛乐乐, 张建良,等. 钢铁企业烧结制粒工艺与设备优化进展及趋势[J]. 钢铁, 2021, 56(10): 28-35.Liu Zhengjian, Niu Lele, Zhang Jianliang, et al. Status quo and trend of technology and equipment optimization for sintering granulation in iron and steel enterprises[J]. lron and Steel, 2021, 56(10): 28-35. [9] Liu Peiqiu. Tests to increase the amount of steel slag used in sintering dosing[J]. Meishan Technology, 2012(5):39-41. (刘佩秋. 提高烧结配加钢渣用量的试验[J]. 梅山科技, 2012(5):39-41.Liu Peiqiu. Tests to increase the amount of steel slag used in sintering dosing[J]. Meishan Technology, 2012(5): 39-41. [10] Kadyrov A S, Kunaev V A, Georgiadi I V. Prospects for processing of ferrous metallurgical waste based on ArcelorMittal Temirtau experience[J]. Metallurgist, 2018,62(1-2):22-28. doi: 10.1007/s11015-018-0620-3 [11] Guo Yuhua, Qie Junmao, Zhang Chunxia, et al. Material flow analysis of zinc during the manufacturing process in integrated steel mills in China[J]. Journal of Industrial Ecology , 2021,25(4):1009-1020. [12] Zhang Jianliang, Fu Hongyuan, Liu Yanxiang, et al. Review on biomass metallurgy: pretreatment technology, metallurgical mechanism and process design[J]. International Journal of Minerals, Metallurgy and Materials, 2022,29(6):1133-1149. doi: 10.1007/s12613-022-2501-9 [13] Wan Xinyuan, Wang Xitang, Wang Zhoufu, et al. Preparation of dolomite clinker with steel slag as sintering agent[J]. Refractories, 2019, 53(4): 298. (万新源, 王玺堂, 王周福,等. 以钢渣为烧结剂制备白云石熟料[J]. 耐火材料, 2019, 53(4): 298.Wan Xinyuan, Wang Xitang, Wang Zhoufu, et al. Preparation of dolomite clinker with steel slag as sintering agent[J]. Refractories, 2019, 53(4): 298. [14] Zhao Lijie, Zhang Fang. Comprehensive utilization and development prospect of steel slag resources[J]. Materials Reports, 2021, 34(Z2): 319-322. (赵立杰, 张芳. 钢渣资源综合利用及发展前景展望[J]. 材料导报, 2021, 34(Z2): 319-322.Zhao Lijie, Zhang Fang. Comprehensive utilization and development prospect of steel slag resources[J]. Materials Reports, 2021, 34(Z2): 319-322. [15] Han Shiwang, Wang Luyuan, Zhang Xingyu, et al. Synergetic resource utilization of steel slag and sludge and it's research progress[J]. Chemical Bulletin, 2023, 86(1): 83-90. (韩世旺, 王鲁元, 张兴宇, 等. 钢渣与污泥协同资源化研究进展[J]. 化学通报, 2023, 86(1): 83-90.Han Shiwang, Wang Luyuan, Zhang Xingyu, et al. Synergetic resource utilization of steel slag and sludge and it's research progress[J]. Chemical Bulletin, 2023, 86(1): 83-90. [16] Zhang Jianliang, Kan Yonghai, Zhang Shijun, et al. Application of full active lime intensified sintering technology in ultra thick layer[J]. Iron and Steel, 2020, 55(8): 56-61. (张建良, 阚永海, 张士军,等. 全活性石灰强化烧结技术在超厚料层中的应用[J]. 钢铁, 2020, 55(8): 56-61.Zhang Jianliang, Kan Yonghai, Zhang Shijun, et al. Application of full active lime intensified sintering technology in ultra thick layer[J]. Iron and Steel, 2020, 55(8): 56-61. [17] Liu Zhengjian, Li Sida, Zhang Jianliang, et al. Production practice and development trend of iron ore sinter with ultra-high basicity[J]. Iron and Steel, 2022, 57(1): 39-47. (刘征建, 李思达, 张建良,等. 国内超高碱度烧结矿生产实践及发展趋势[J]. 钢铁, 2022, 57(1): 39-47.Liu Zhengjian, Li Sida, Zhang Jianliang, et al. Production practice and development trend of iron ore sinter with ultra-high basicity[J]. Iron and Steel, 2022, 57(1): 39-47. [18] Ma Yunfei, Li Qing, Zhang Jianliang, et al. Synergistic optimization model of sintering ore allocation cost and energy consumption based on PSO-VIKOR[J]. Chinese Journal of Engineering, 2023, 45(11): 1868-1877. (马云飞, 李擎, 张建良,等. 基于 PSO-VIKOR 的烧结配矿成本与能耗协同优化模型[J]. 工程科学学报, 2023, 45(11): 1868-1877.Ma Yunfei, Li Qing, Zhang Jianliang, et al. Synergistic optimization model of sintering ore allocation cost and energy consumption based on PSO-VIKOR[J]. Chinese Journal of Engineering, 2023, 45(11): 1868-1877. [19] Cao Liu, Shen Weiguo, Huang Jiaqi, et al. Process to utilize crushed steel slag in cement industry directly: Multi-phased clinker sintering technology[J]. Journal of Cleaner Production, 2019,217:520-529. doi: 10.1016/j.jclepro.2019.01.260 [20] Wang Yanan, Zhao Deqiang, Li Zhengwang, et al. Mineral phase transformation and properties of steel slag in process of melting and sintering[J]. Bulletin of the Chinese Ceramic Society, 2023, 42(5): 1731-1739. (王亚楠, 赵德强, 李正旺, 等. 钢渣烧结过程的矿物相转变及性能研究[J]. 硅酸盐通报, 2023, 42(5): 1731-1739.Wang Yanan, Zhao Deqiang, Li Zhengwang, et al. Mineral phase transformation and properties of steel slag in process of melting and sintering[J]. Bulletin of the Chinese Ceramic Society, 2023, 42(5): 1731-1739. [21] Zhang Zhaohui, Liao Jielong, Ju Jiantao, et al. Treatment process and utilization technology of steel slag in china and abroad[J]. Journal of Iron and Steel Research, 2013, 25(7): 1-4. (张朝晖, 廖杰龙, 巨建涛, 等. 钢渣处理工艺与国内外钢渣利用技术[J]. 钢铁研究学报, 2013, 25(7): 1-4.Zhang Zhaohui, Liao Jielong, Ju Jiantao, et al. Treatment process and utilization technology of steel slag in china and abroad[J]. Journal of Iron and Steel Research, 2013, 25(7): 1-4. [22] Li Bing, Tang Biao, Ma Zhen, et al. Physical and chemical properties of steel slag and utilization technology of steel slag at home and abroad[J]. IOP Conference Series: Earth and Environmental Science, 2019, 242(3): 32012. [23] Xie Hao, Li Gang, Lü Xuewei, et al. Effect of preformed calcium ferrite addition on sintering behaviorof vanadium titanomagnetite[J]. Iron Steel Vanadium Titanium, 2023, 44(4): 117-124. (谢皓, 李刚, 吕学伟, 等. 预制铁酸钙技术对钒钛磁铁矿烧结行为的影响[J]. 钢铁钒钛, 2023, 44(4): 117-124.Xie Hao, Li Gang, Lü Xuewei, et al. Effect of preformed calcium ferrite addition on sintering behaviorof vanadium titanomagnetite[J]. Iron Steel Vanadium Titanium, 2023, 44(4): 117-124. [24] Du Chuanming, Yu Yaohui, Yuan Lei, et al. Research status and development trend of phosphorus separation and recovery from steelmaking slag[J]. Iron and Steel, 2020, 55(12): 1-9. (杜传明, 于耀辉, 袁磊, 等. 钢渣中磷分离及回收的研究现状和发展趋势[J]. 钢铁, 2020, 55(12): 1-9.Du Chuanming, Yu Yaohui, Yuan Lei, et al. Research status and development trend of phosphorus separation and recovery from steelmaking slag[J]. Iron and Steel, 2020, 55(12): 1-9. [25] Zhou Chaogang, Yang Huize, Ai Liqun, et al. Research status and prospect of recycling technology of converter slag containing phosphorus[J]. Iron and Steel, 2021, 56(2): 22. (周朝刚, 杨会泽, 艾立群, 等. 转炉含磷钢渣循环利用技术的研究现状及展望[J]. 钢铁, 2021, 56(2): 22.Zhou Chaogang, Yang Huize, Ai Liqun, et al. Research status and prospect of recycling technology of converter slag containing phosphorus[J]. Iron and Steel, 2021, 56(2): 22. [26] Hao Ning, Tian Zhihong, Jia Yanan, et al. Effect of CaO/SiO2 on phase composition and content of steel slag[J]. China Metallurgy, 2021, 31(4): 84-90. (郝宁, 田志红, 贾雅楠, 等. CaO/SiO2 对钢渣平衡物相的组成及含量的影响[J]. 中国冶金, 2021, 31(4): 84-90.Hao Ning, Tian Zhihong, Jia Yanan, et al. Effect of CaO/SiO2 on phase composition and content of steel slag[J]. China Metallurgy, 2021, 31(4): 84-90. [27] Zhang Dayong. Discussion on the measures of comprehensive utilisation of iron-containing wastes in iron and steel smelting[J]. Science, Technology and Innovation, 2018(27):195-196. (张大勇. 钢铁冶炼中综合利用含铁废料的措施探讨[J]. 科学技术创新, 2018(27):195-196.Zhang Dayong. Discussion on the measures of comprehensive utilisation of iron-containing wastes in iron and steel smelting[J]. Science, Technology and Innovation, 2018(27): 195-196. [28] Hu Peiwei, Xie Zhicheng, Hu Bing, et al. Comprehensive utilization status and development of vanadium-bearing solid wastes[J]. Conservation and Utilization of Mineral Resources, 2020, 40(5): 144-152. (胡佩伟, 谢志诚, 胡兵, 等. 含钒固废综合利用现状及发展[J]. 矿产保护与利用, 2020, 40(5): 144-152.Hu Peiwei, Xie Zhicheng, Hu Bing, et al. Comprehensive utilization status and development of vanadium-bearing solid wastes[J]. Conservation and Utilization of Mineral Resources, 2020, 40(5): 144-152. [29] Liu Yang, Zhang Chunxia. Comprehensive utilization situation and development trend of iron and steel slag in china and abroad[J]. Multipurpose Utilization of Mineral Resources, 2019,(2):21-25. (刘洋, 张春霞. 钢铁渣的综合利用现状及发展趋势[J]. 矿产综合利用, 2019,(2):21-25.Liu Yang, Zhang Chunxia. Comprehensive utilization situation and development trend of iron and steel slag in china and abroad[J]. Multipurpose Utilization of Mineral Resources, 2019, (2): 21-25. [30] Qie Junmao, Zhang Chunxia, Li Xiuping, et al. Lower SiO2 emissions in the sintering process utilizing the difference of sulphur contents of iron ores[J]. ISIJ International, The Iron and Steel Institute of Japan, 2017,57(12):2115-2123. [31] Han Xiuli, Wang Haifeng, Liu Lina, et al. Influence of basicity on microstructure of vanadium-titanium magnetite sinter[J]. Iron Steel Vanadium Titanium, 2009, 30(3): 56-60. (韩秀丽, 王海峰, 刘丽娜, 等. 碱度对钒钛烧结矿显微结构的影响[J]. 钢铁钒钛, 2009, 30(3): 56-60.Han Xiuli, Wang Haifeng, Liu Lina, et al. Influence of basicity on microstructure of vanadium-titanium magnetite sinter[J]. Iron Steel Vanadium Titanium, 2009, 30(3): 56-60. -

下载:

下载: