Research on theoretical combustion temperature control of V-Ti magnetite blast furnace smelting

-

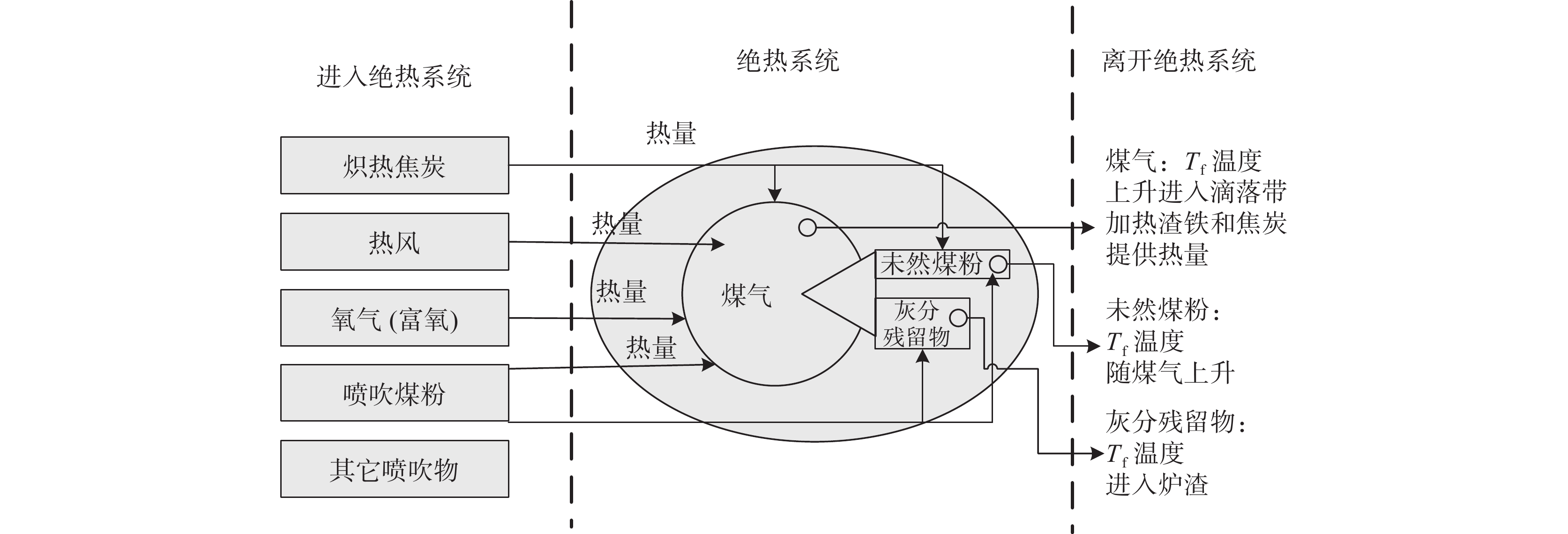

摘要: 风口前理论燃烧温度是评价高炉炉缸热状态的重要参数之一。在传统理论燃烧温度计算模型基础上,综合考虑了灰分、未燃煤粉、SiO2气化率等因素对理论燃烧温度的影响,修正了理论燃烧温度计算模型。研究结果表明,传统计算模型忽略的因素对理论燃烧温度的影响程度为53~55 ℃;富氧率、喷煤量、鼓风湿度、风温、煤粉燃料率、煤粉预热温度、灰分、SiO2气化率对理论燃烧温度的影响程度依次递减;攀枝花钢钒公司高炉适宜的理论燃烧温度在

2160 ~2320 ℃,鼓风湿度恒定的情况下,理论燃烧温度适宜的控制范围在2220 ~2280 ℃。将理论燃烧温度实时在线计算应用于高炉生产操作调控后,有效促进了高炉稳定顺行,降低了高炉燃料消耗。Abstract: The theoretical combustion temperature in front of the tuyere is one of the important parameters for evaluating the thermal state of the blast furnace hearth. On the basis of the traditional theoretical combustion temperature calculation model, the influence of ash content, unburned coal powder, and SiO2 gasification rate on the theoretical combustion temperature was comprehensively considered, and the theoretical combustion temperature calculation model was revised. The research results indicate that, the influence of factors ignored by traditional calculation models on the theoretical combustion temperature ranges from 53 to 55 ℃. The influence of oxygen enrichment rate, coal injection rate, blowing humidity, air temperature, coal fuel rate, coal preheating temperature, ash content, and SiO2 gasification rate on the theoretical combustion temperature decreases in sequence. The suitable theoretical combustion temperature control range for the blast furnace at Panzhihua Steel & Vanadium Co., Ltd. is2160 ~2320 ℃. And under the condition of constant blowing humidity, the suitable control range for the theoretical combustion temperature is2220 ~2 28 0 ℃. After applying real-time online calculation of theoretical combustion temperature to the regulation of blast furnace production operations, it effectively promotes-

Key words:

- blast furnace /

- theoretical combustion temperature /

- calculation model /

- revise

-

表 1 炼铁常用气体热容系数数据

Table 1. Heat capacity coefficient data of commonly used gases in ironmaking

气体 a b c 温度范围/ ℃ O2 7.16 0.00100 − 40000 25~ 2700 N2 6.66 0.00102 0 25~ 2700 H2 6.52 0.00078 12000 25~ 2700 CO 6.79 0.00098 − 11000 25~ 2700 H2O 7.17 0.00256 8000 25~ 2700 表 2 焦炭和喷吹煤粉成分

Table 2. Compositions of coke and pulverized coal injection

% 固定C 挥发分 灰分 水分 灰中成分 CaO SiO2 MgO Al2O3 焦炭 86.14 1.27 12.75 0 4.49 53.61 1.95 23.82 煤粉 76.81 12.21 12.52 0.50 7.14 47.61 2.98 22.35 表 3 喷吹煤粉元素含量和发热值

Table 3. Element content and calorific value of coal injection

C ad/% H ad/% N ad/% O ad/% 低位发热值 /(J·g−1) 煤粉 77.62 3.41 0.8 3.01 32041.37 表 4 相关高炉操作参数

Table 4. Relevant blast furnace operating parameters

风量/

(m3·min−1)风温/

℃富氧量/

(m3·h−1)鼓风湿度/

(g·m−3)喷煤量/

(t·h−1)焦比/

(kg·t−1)煤比/

(kg·t−1)煤粉温度/

℃煤粉燃烧率/

%日产量/

t3000 1210 3500 9 15.8 440 110 60 80 3350 表 5 各变量对理论燃烧温度的影响

Table 5. The influence of various variables on the theoretical combustion temperature

变量 变化幅度 Tf变化/ ℃ 风温 10 +6.94 煤粉预热温度 10 +0.45 喷煤比 10 −15.02 鼓风湿度 1 -4.95 煤粉燃烧率 10 +5.47 喷煤速率 1 −10.76 富氧率 1 +45.6 SiO2气化率 1 −1 喷吹煤灰分 1 −1.42 焦炭灰分 1 -2.4 注:变量变化幅度:风温和煤粉预热温度以10 ℃计,喷煤比以10 kg/t计,鼓风湿度以1 g/m³计,煤粉燃烧率以10%计,喷煤速率以1 t/h计,其余以变化1%计。 表 6 各国钢铁企业理论燃烧温度控制范围

Table 6. Theoretical combustion temperature control range of steel enterprises in various countries

国家 公司 Tf / ℃ 国家 公司 Tf / ℃ 荷兰 hoogyens 2150 ~2350 德国 shwelgen 2250 ~2300 法国 索拉克 2100 ~2160 中国 宝钢 2000 ~2300 日本 福山 2200 ~2400 中国 首钢A高炉 2165 ~2365 日本 君津3# 2300 ~2350 中国 首钢B高炉 2165 ~2280 日本 鹿岛3# 2400 ~2450 中国 国丰1# 2100 ~2300 表 7 富氧、喷煤、鼓风湿度搭配方案

Table 7. Matching scheme for oxygen enrichment rate, coal injection, and air blast humidity

富氧 喷煤/(kg·t−1) 鼓风湿度(HB)/(g·m−3) 高 高(160) 高(18) 高 高(160) 低 (6) 高 低(110) 低 (6) 低 高(160) 高(18) 低 低(110) 高(18) 低 低(110) 低 (6) 表 8 2018年理论燃烧温度上线运行前后攀钢钒高炉主要技术经济指标

Table 8. Main technical and economic indicators of blast furnace before and after the theoretical combustion temperature was put into operation in 2018 at Pansteel

高炉 利用系数/[t·(m3·d−1)] 燃料比/(kg·t−1) 1~6月 7~12月 比较 1~6月 7~12月 比较 1# 2.713 2.745 0.032 566.1 558.0 −8.1 2# 2.711 2.816 0.105 566.1 556.9 −9.2 3# 2.695 2.680 −0.014 566.2 561.2 −5.0 新3# 2.179 2.315 0.136 580.4 573.6 −6.8 -

[1] Wu Shengli, Yu Xiaobo, Chen Hui, et al. Calculation of theoretical flame temperature in a blast furnace[J]. Journal of University of Science and Technology Beijing, 2008,12(30):1432-1438. (吴胜利, 余晓波, 陈辉,等. 高炉理论燃烧温度的计算[J]. 北京科技大学学报, 2008,12(30):1432-1438.Wu Shengli, Yu Xiaobo, Chen Hui, et al. Calculation of theoretical flame temperature in a blast furnace[J]. Journal of University of Science and Technology Beijing, 2008, 12(30): 1432-1438. [2] Na Shuren. Analysis of ironmaking calculation[M]. Beijing, Metallurgical Industry Press, 2010. (那树人. 炼铁计算辨析[M]. 北京, 冶金工业出版社, 2010.Na Shuren. Analysis of ironmaking calculation[M]. Beijing, Metallurgical Industry Press, 2010. [3] Sun Lianyou, Xu Shugang. The calculation of the theoretical burning temperature in front of the tuyere[J]. Bengang Technology, 2008(4):8-10. (孙连友, 徐书刚. 风口前理论燃烧温度的简易计算[J]. 本钢技术, 2008(4):8-10.Sun Lianyou, Xu Shugang. The calculation of the theoretical burning temperature in front of the tuyere[J]. Bengang Technology, 2008(4): 8-10. [4] Xu Shugang, Tian Hui. The calculation on line of theoretical burning temperature in front of the tuyere[J]. Bengang Technology, 2000(4):7-8. (徐书刚, 田辉. 风口前理论燃烧温度的在线计算[J]. 本钢技术, 2000(4):7-8.Xu Shugang, Tian Hui. The calculation on line of theoretical burning temperature in front of the tuyere[J]. Bengang Technology, 2000(4): 7-8. [5] Zhang Jianliang, Yang Tianjun, Gao Zhengkai, et al. A new method to determine the decomposition heat of coal during PCI for BF[J]. Journal of University of Science and Technology Beijing, 2001,4(23):308-310. (张建良, 杨天钧, 高征铠,等. 高炉喷煤过程煤粉分解热确定的新方法[J]. 北京科技大学学报, 2001,4(23):308-310.Zhang Jianliang, Yang Tianjun, Gao Zhengkai, et al. A new method to determine the decomposition heat of coal during PCI for BF[J]. Journal of University of Science and Technology Beijing, 2001, 4(23): 308-310. [6] Zhang Jianliang, Qiu Jiayong, Guo Hongwei. Research of theoretical flame temperature in blast furnace tuyere[J]. Iron and Steel, 2012,7(47):10-14. (张建良, 邱家用, 国宏伟. 高炉风口区理论燃烧温度的研究[J]. 钢铁, 2012,7(47):10-14.Zhang Jianliang, Qiu Jiayong, Guo Hongwei. Research of theoretical flame temperature in blast furnace tuyere[J]. Iron and Steel, 2012, 7(47): 10-14. [7] Zhang Er’hua, Wu Keng, Wan Peng. Effect of SiO2 reduction on the theoretical flame temperature before the tuyere in a blast furnace[J]. Journal of University of Science and Technology Beijing, 2010,11(32):1406-1411. (张二华, 吴铿, 万鹏. SiO2还原对高炉风口前理论燃烧温度的影响[J]. 北京科技大学学报, 2010,11(32):1406-1411.Zhang Er’hua, Wu Keng, Wan Peng. Effect of SiO2 reduction on the theoretical flame temperature before the tuyere in a blast furnace[J]. Journal of University of Science and Technology Beijing, 2010, 11(32): 1406-1411. [8] Liu Chengsong, Li Jingshe, Tang Haiyan. Improvements on calculation model of theoretical combustion temperature in the tuyere raceway of BF[J]. Journal of Northeastern University(Natural Science), 2015,3(36):392-396. (刘成松, 李京社, 唐海燕. 高炉风口理论燃烧温度计算模型的改良[J]. 东北大学学报(自然科学版), 2015,3(36):392-396.Liu Chengsong, Li Jingshe, Tang Haiyan. Improvements on calculation model of theoretical combustion temperature in the tuyere raceway of BF[J]. Journal of Northeastern University(Natural Science), 2015, 3(36): 392-396. [9] Dai Bing, Zhang Jianliang, Su Dongxue. Development and practice of theoretical combustion temperature calculation model of blast furnace[J]. Metallurgical Industry Automation, 2012,3(36):54-57. (代兵, 张建良, 苏东学. 高炉理论燃烧温度计算模型的开发与实践[J]. 冶金自动化, 2012,3(36):54-57.Dai Bing, Zhang Jianliang, Su Dongxue. Development and practice of theoretical combustion temperature calculation model of blast furnace[J]. Metallurgical Industry Automation, 2012, 3(36): 54-57. [10] Wang Guangwei, Zhang Jianliang, Su Buxin. Calculation of theoretical combustion temperature in a blast furnace with consideration of chemical equilibrium[J]. Iron and Steel, 2012,4(47):9-13. (王广伟, 张建良, 苏步新. 考虑化学反应平衡的理论燃烧温度计算[J]. 钢铁, 2012,4(47):9-13.Wang Guangwei, Zhang Jianliang, Su Buxin. Calculation of theoretical combustion temperature in a blast furnace with consideration of chemical equilibrium[J]. Iron and Steel, 2012, 4(47): 9-13. [11] Li Zhaoyi. Analysis of the theoretical flame temperature in the front of BF tuyeres[J]. Baosteel Technology, 2011(4):5-7. (李肇毅. 高炉风口理论燃烧温度分析[J]. 宝钢技术, 2011(4):5-7.Li Zhaoyi. Analysis of the theoretical flame temperature in the front of BF tuyeres[J]. Baosteel Technology, 2011(4): 5-7. [12] Xu Hui, Zou Zongshu. Some understanding of theoretical combustion temperature calculation[J]. Ironmaking, 2008,27(4):54. (徐辉, 邹宗树. 对理论燃烧温度计算的一点认识[J]. 炼铁, 2008,27(4):54.Xu Hui, Zou Zongshu. Some understanding of theoretical combustion temperature calculation[J]. Ironmaking, 2008, 27(4): 54. [13] Chen Huabao, Chen Linsen, Xiao Hongtao. Effect of ultra-high oxygen enrichment on theoretical combustion temperature[J]. Research on Iron & Steel, 2011,4(39):1-4. (陈化宝, 陈林森, 肖红涛. 超高富氧对理论燃烧温度的影响[J]. 钢铁研究, 2011,4(39):1-4.Chen Huabao, Chen Linsen, Xiao Hongtao. Effect of ultra-high oxygen enrichment on theoretical combustion temperature[J]. Research on Iron & Steel, 2011, 4(39): 1-4. [14] Guo Honglie, Huang Junjie. Practice of oxygen rich coal injection in Shougang Jingtang 5500 m3 blast furnace[J]. Ironmaking, 2016,6(35):30-32. (郭宏烈, 黄俊杰. 首钢京唐5500 m3高炉富氧喷煤实践[J]. 炼铁, 2016,6(35):30-32.Guo Honglie, Huang Junjie. Practice of oxygen rich coal injection in Shougang Jingtang5500 m3 blast furnace[J]. Ironmaking, 2016, 6(35): 30-32.[15] Chen Lingkun, Li Xiangwei, Lu Longwen. Efficient smelting practice of No. 8 blast furnace at Wuhan Iron and steel group[J]. Ironmaking, 2016,5(35):1-7. (陈令坤, 李向伟, 陆隆文,等. 武钢8号高炉高效冶炼实践[J]. 炼铁, 2016,5(35):1-7.Chen Lingkun, Li Xiangwei, Lu Longwen. Efficient smelting practice of No. 8 blast furnace at Wuhan Iron and steel group[J]. Ironmaking, 2016, 5(35): 1-7. [16] Ren Yanjun, Dong Yansheng, Wang Weidong, et al. Economic analysis of oxygen enrichment rate in blast furnace of Shagang[J]. Ironmaking, 2014,6(33):57-59. (任彦军, 董演生, 王卫东, 等. 沙钢高炉富氧率经济性分析[J]. 炼铁, 2014,6(33):57-59.Ren Yanjun, Dong Yansheng, Wang Weidong, et al. Economic analysis of oxygen enrichment rate in blast furnace of Shagang[J]. Ironmaking, 2014, 6(33): 57-59. [17] Bakker T, Tijhuis G J, Bol L C G M. Developments of operating points of the Umuiden blast furnaces[J]. World Iron and Steel, 2014,4:1-8. (Bakker T, Tijhuis G J, Bol L C G M. 艾莫伊登高炉操作要点的发展[J]. 世界钢铁, 2014,4:1-8.Bakker T, Tijhuis G J, Bol L C G M. Developments of operating points of the Umuiden blast furnaces[J]. World Iron and Steel, 2014, 4: 1-8. -

下载:

下载: