Analysis of inclusions and carbides in mold casting billets of Cr12MoV steel

-

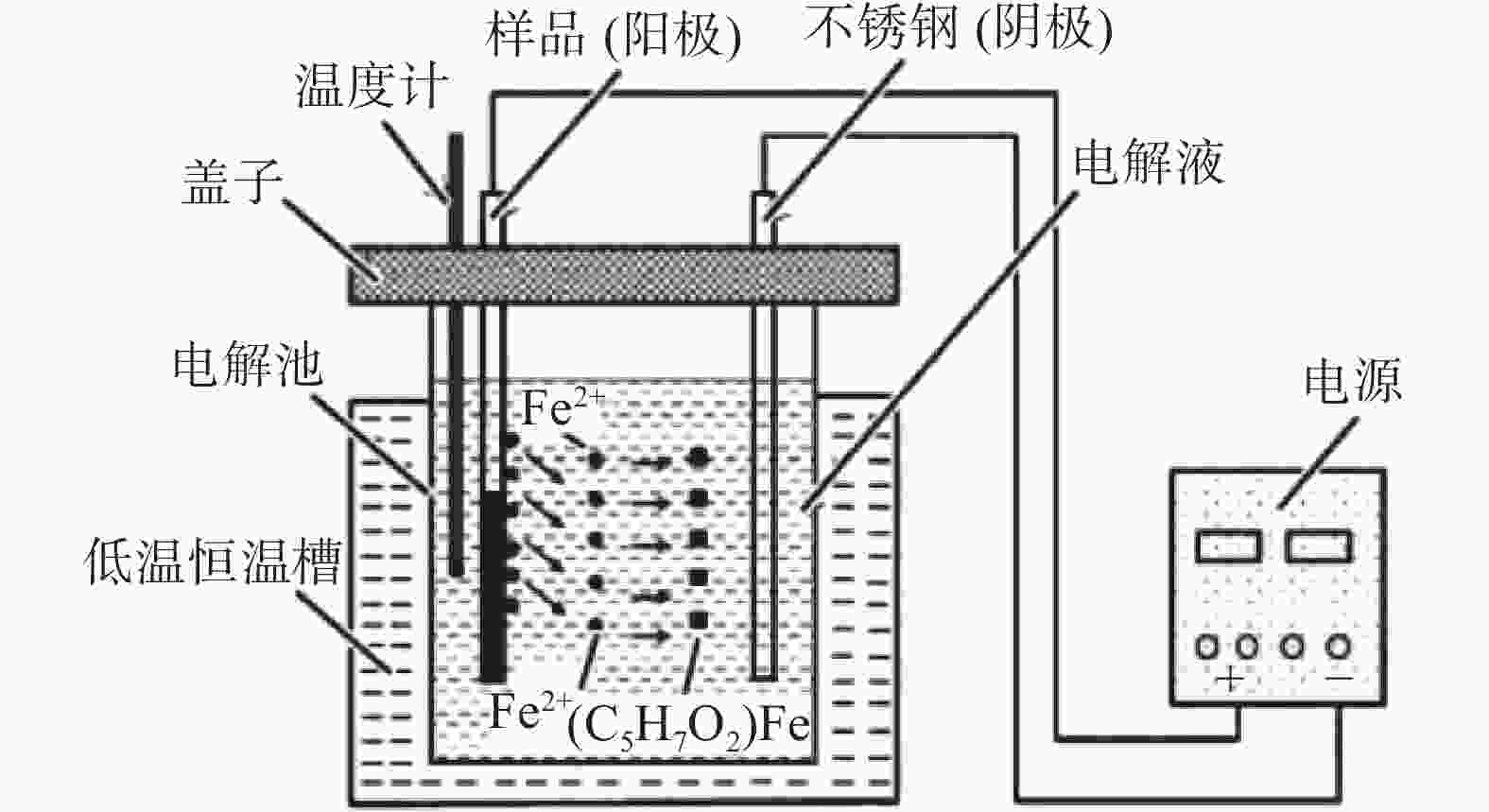

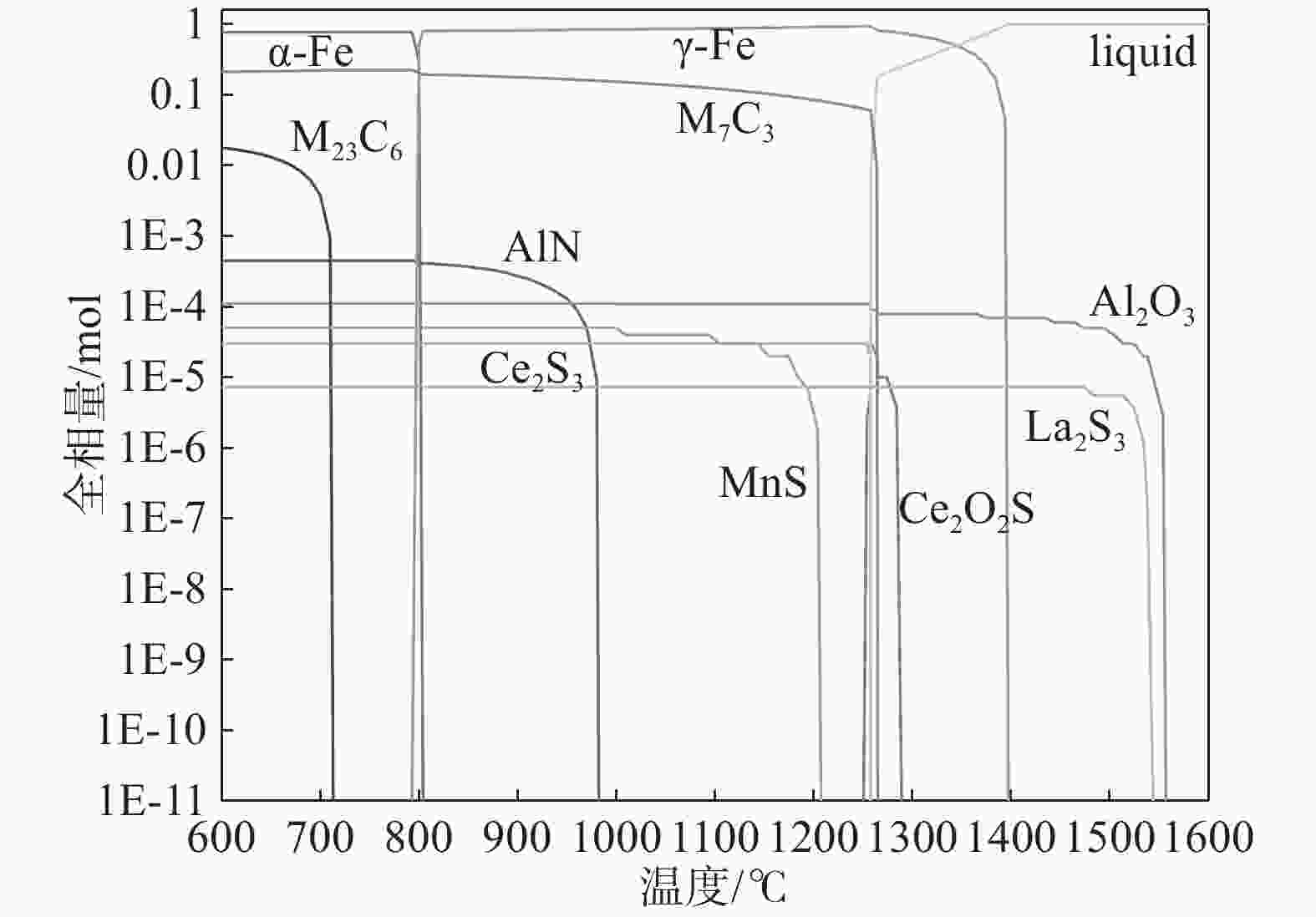

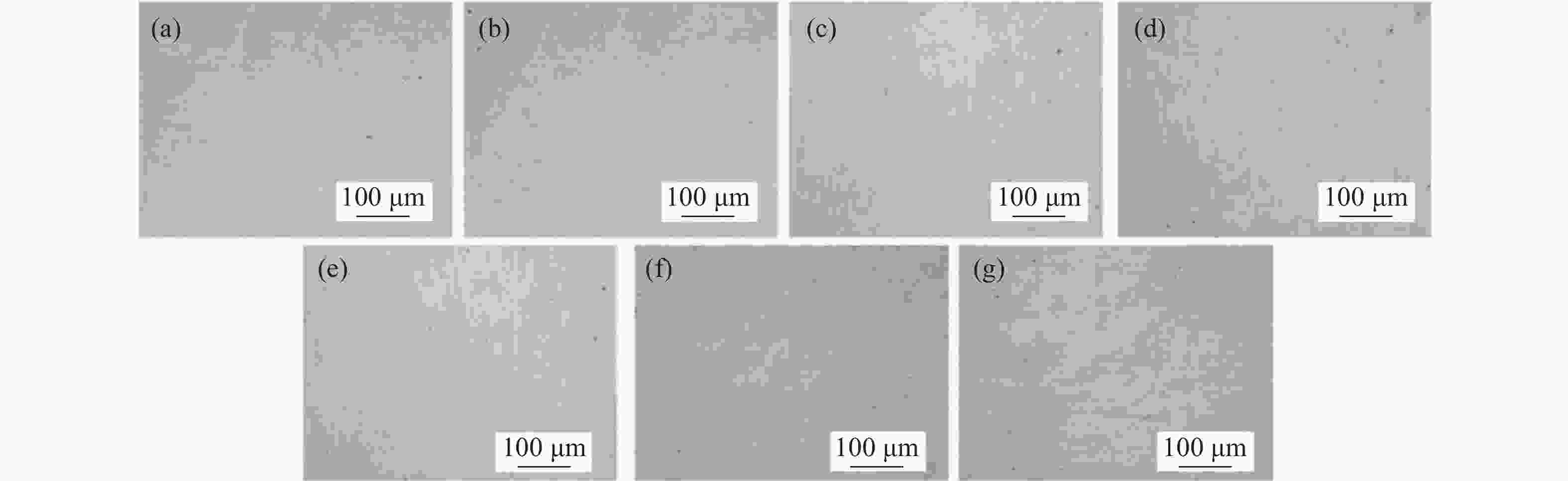

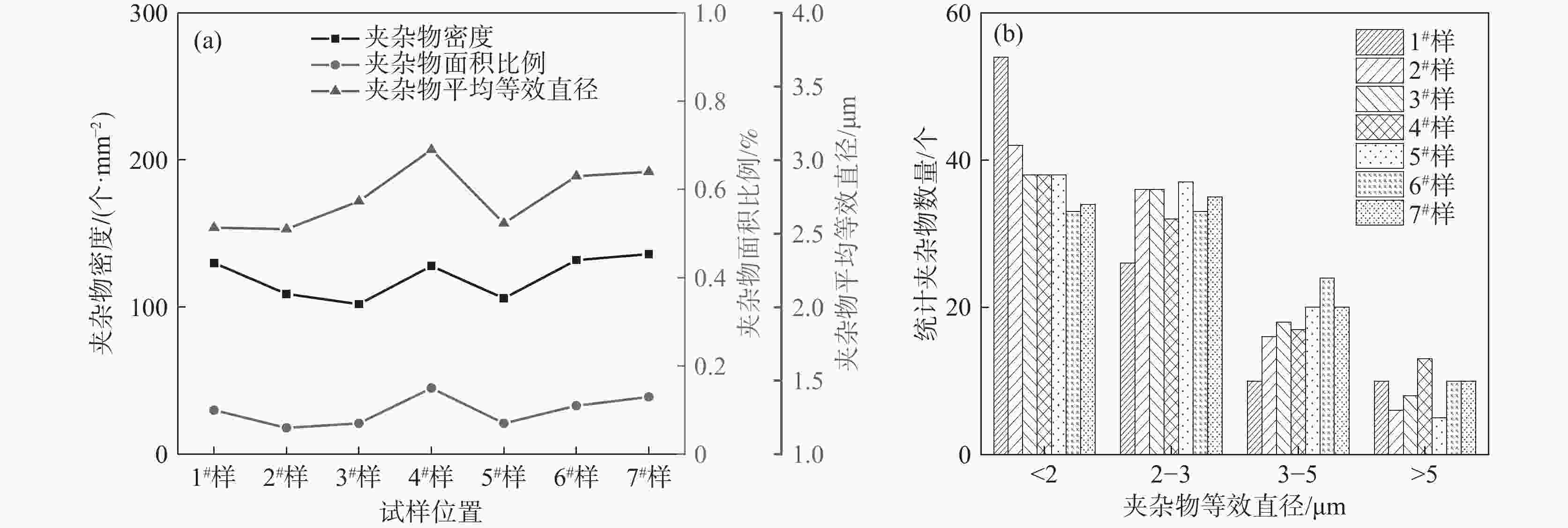

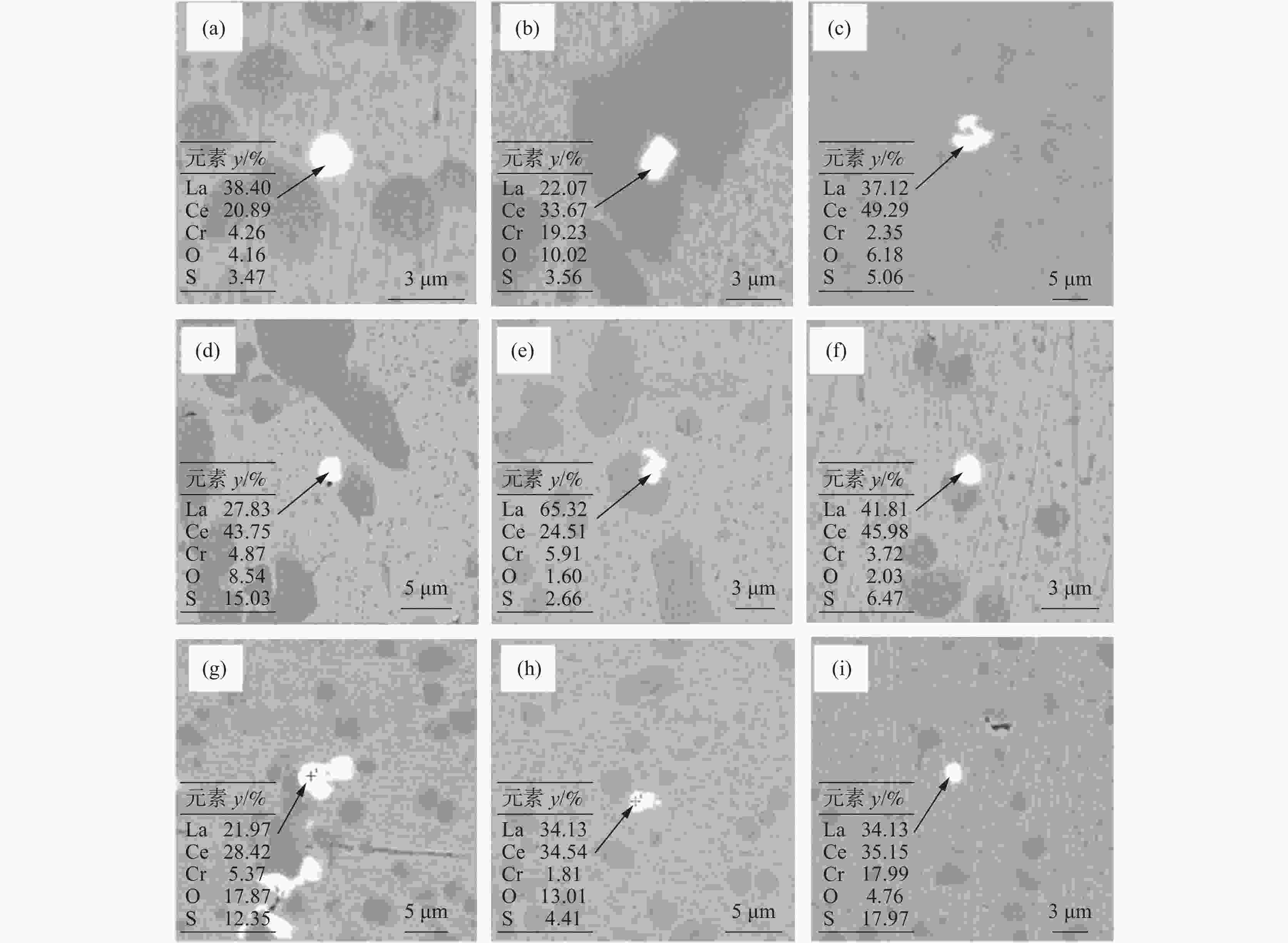

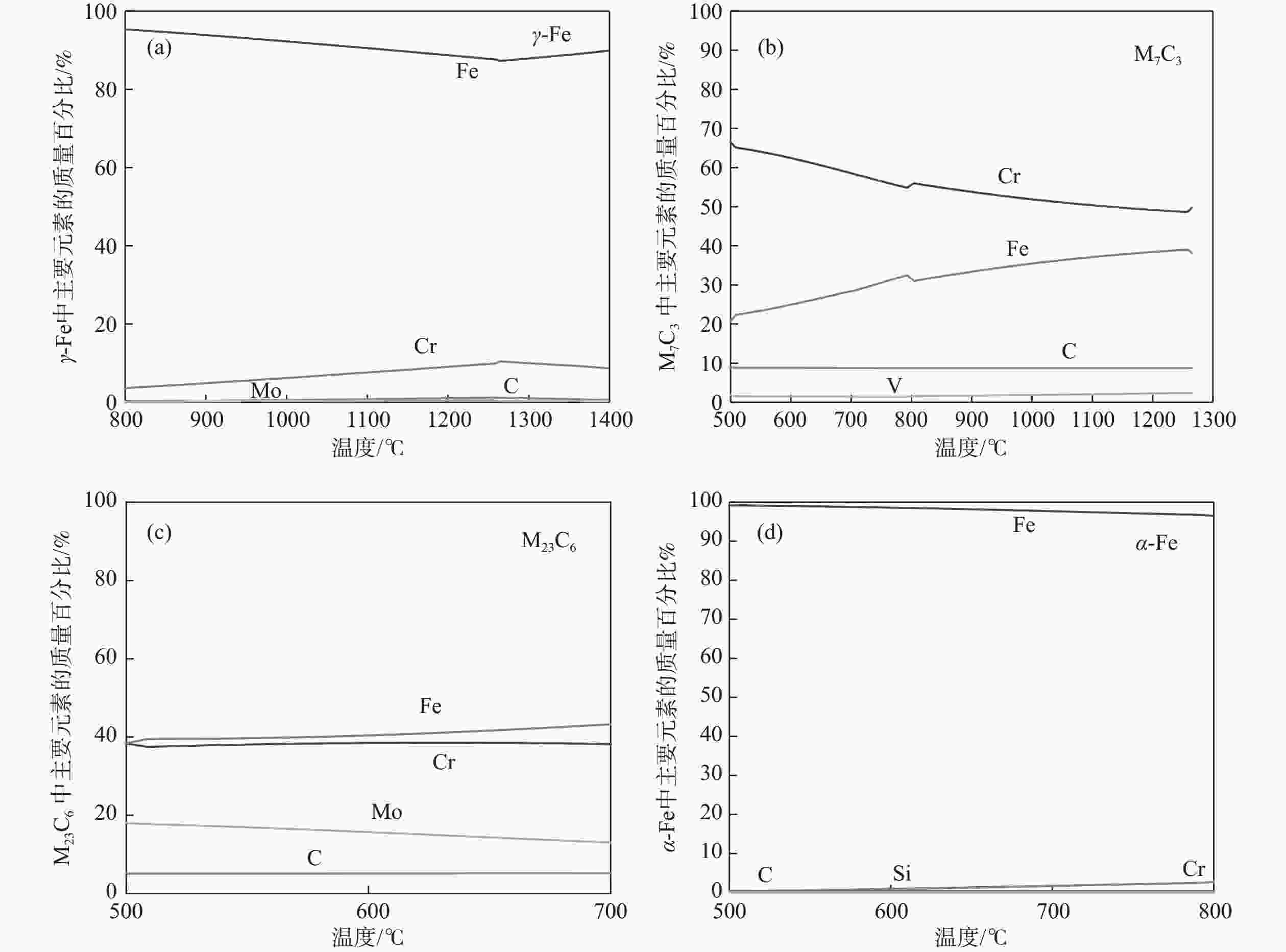

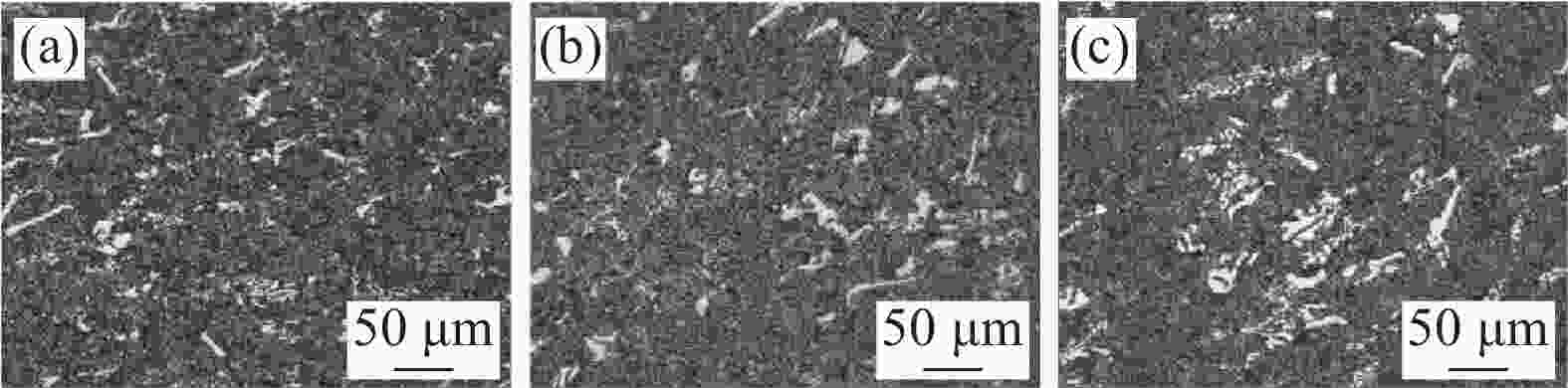

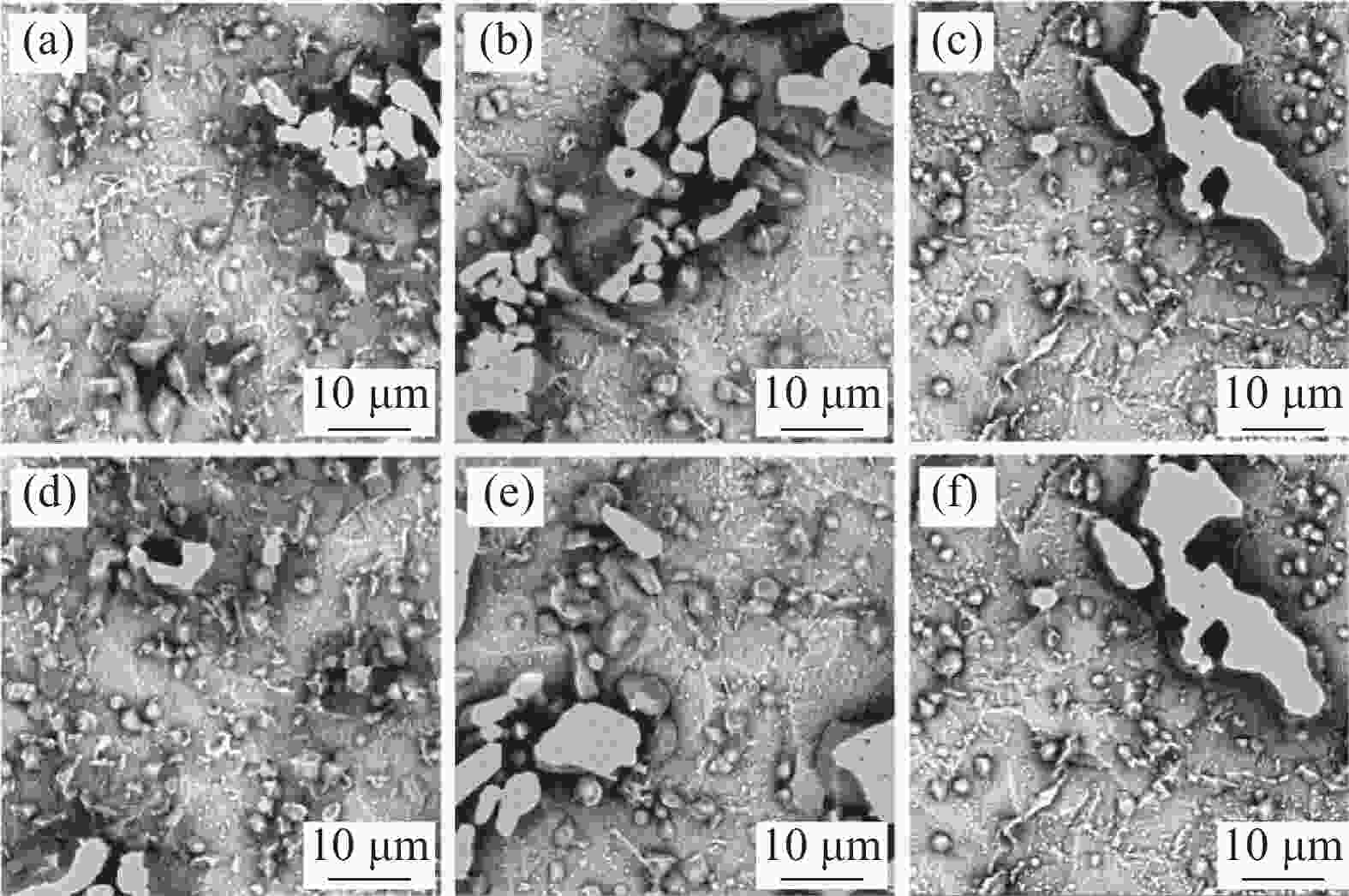

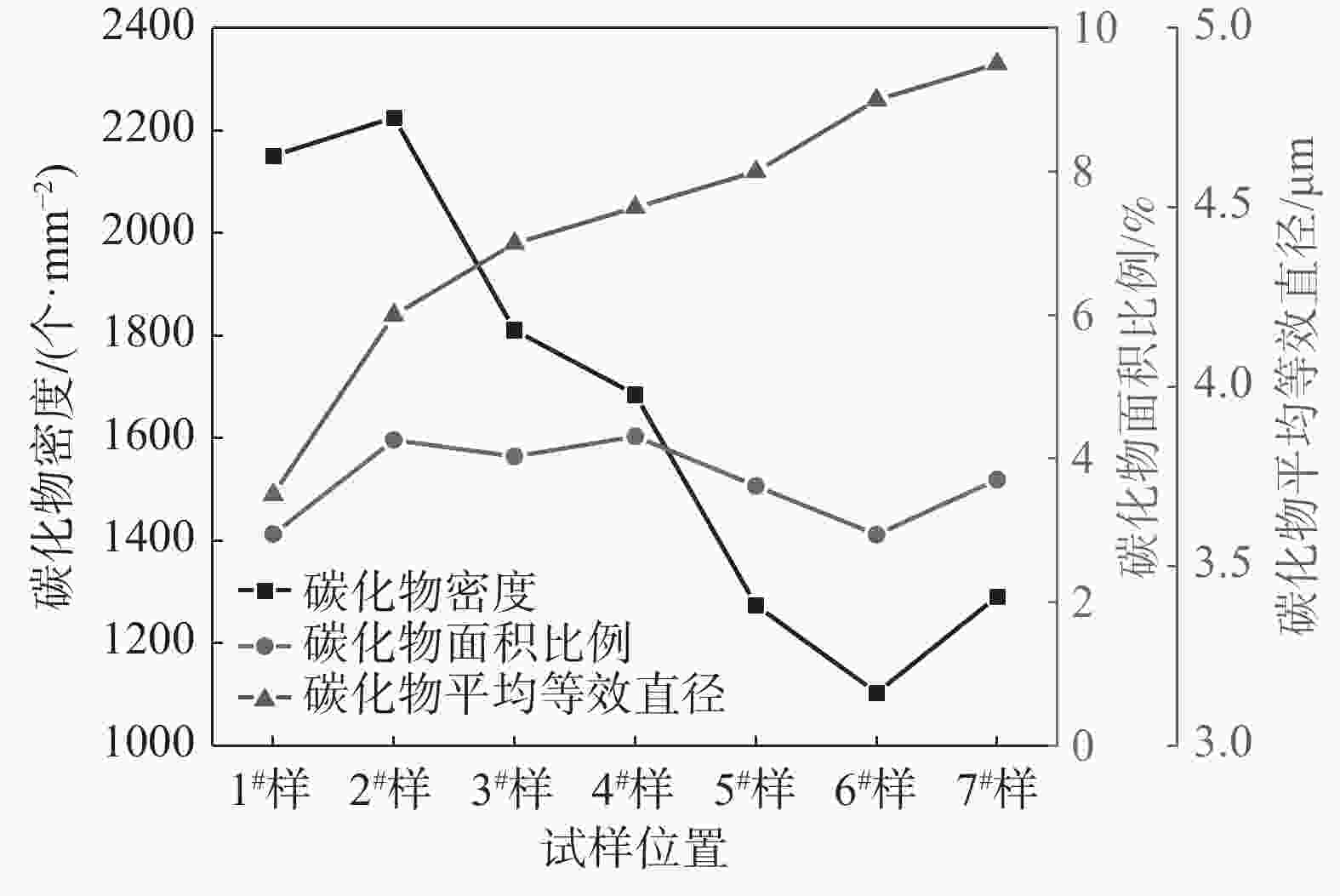

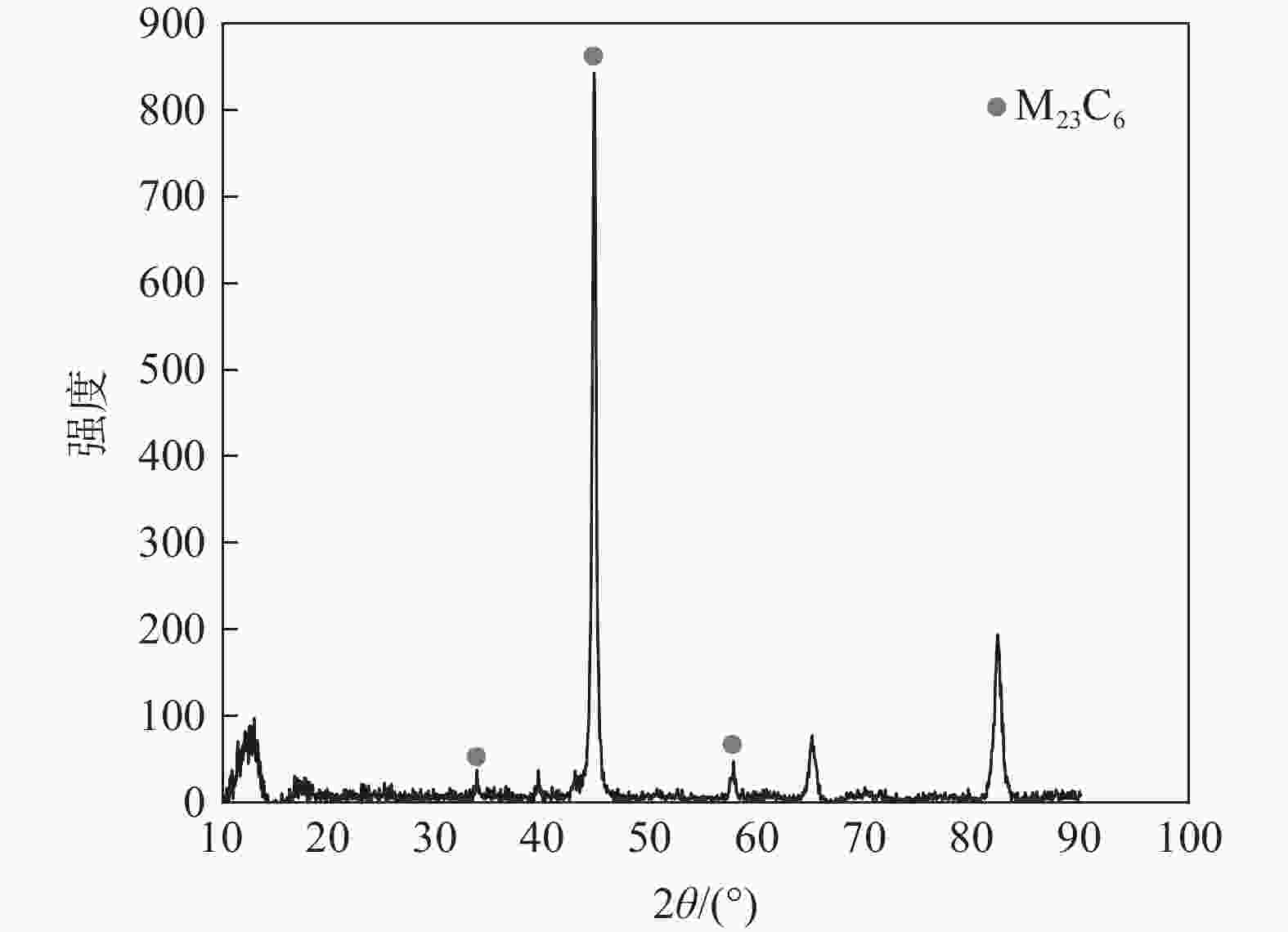

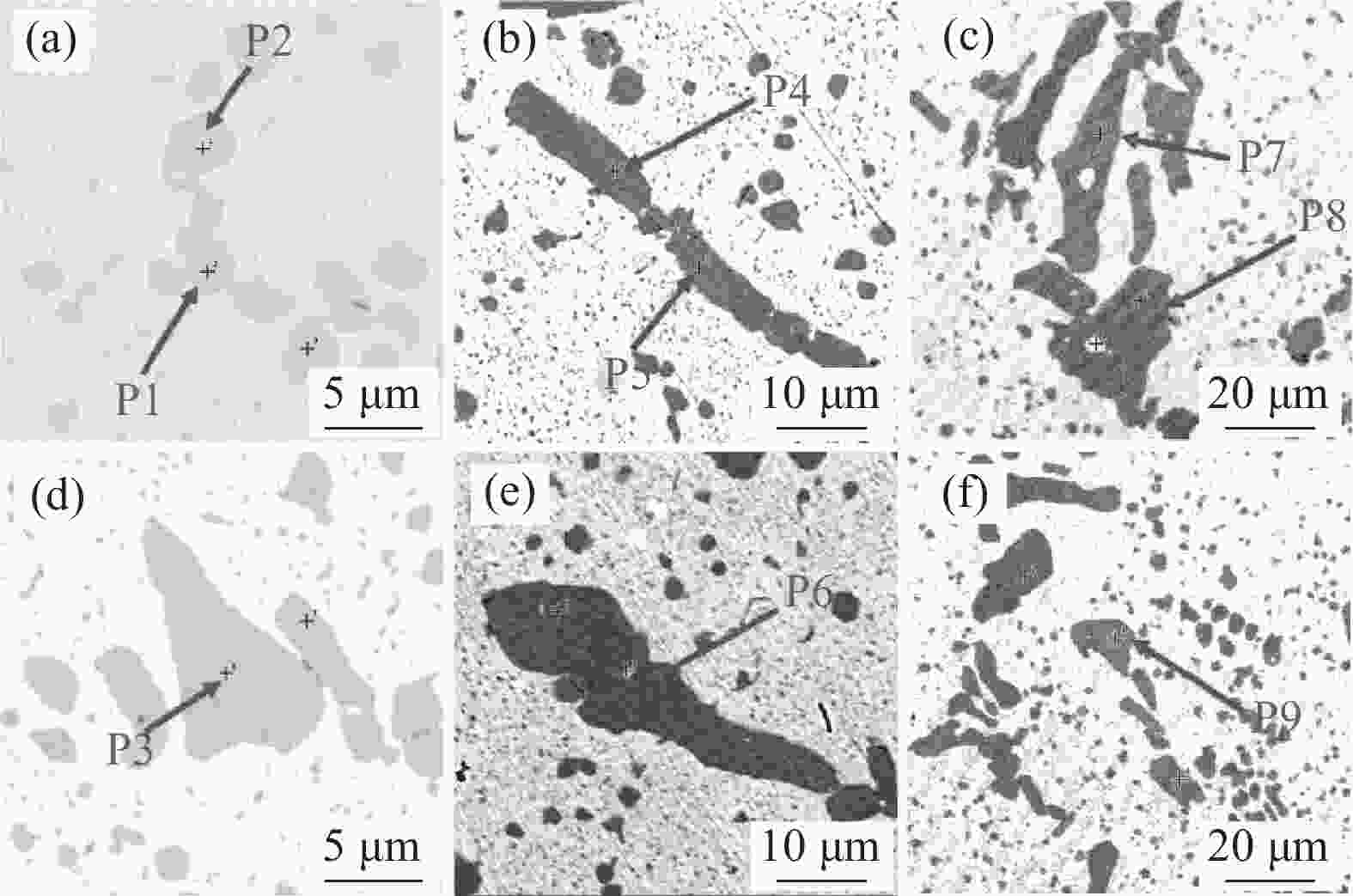

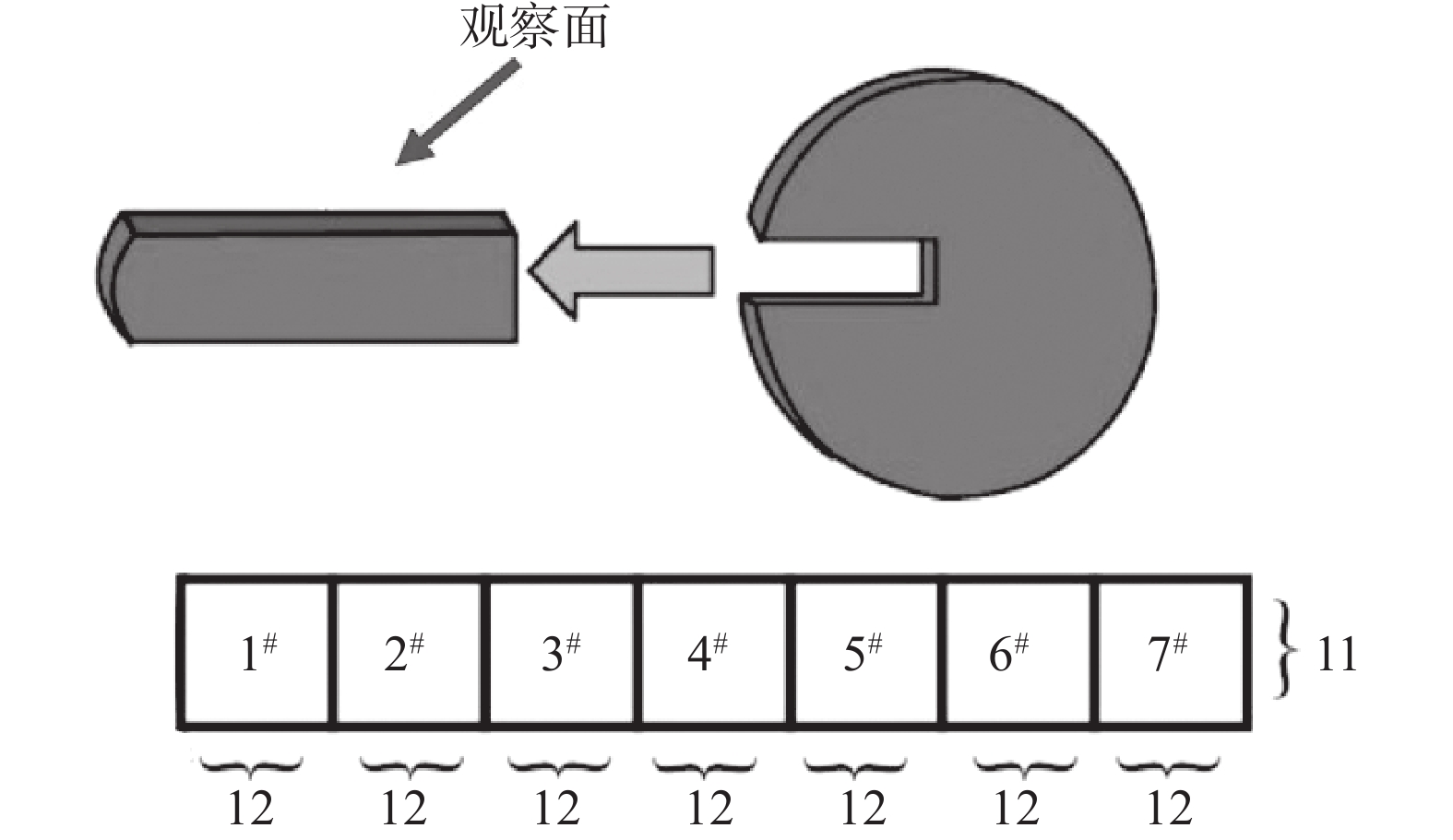

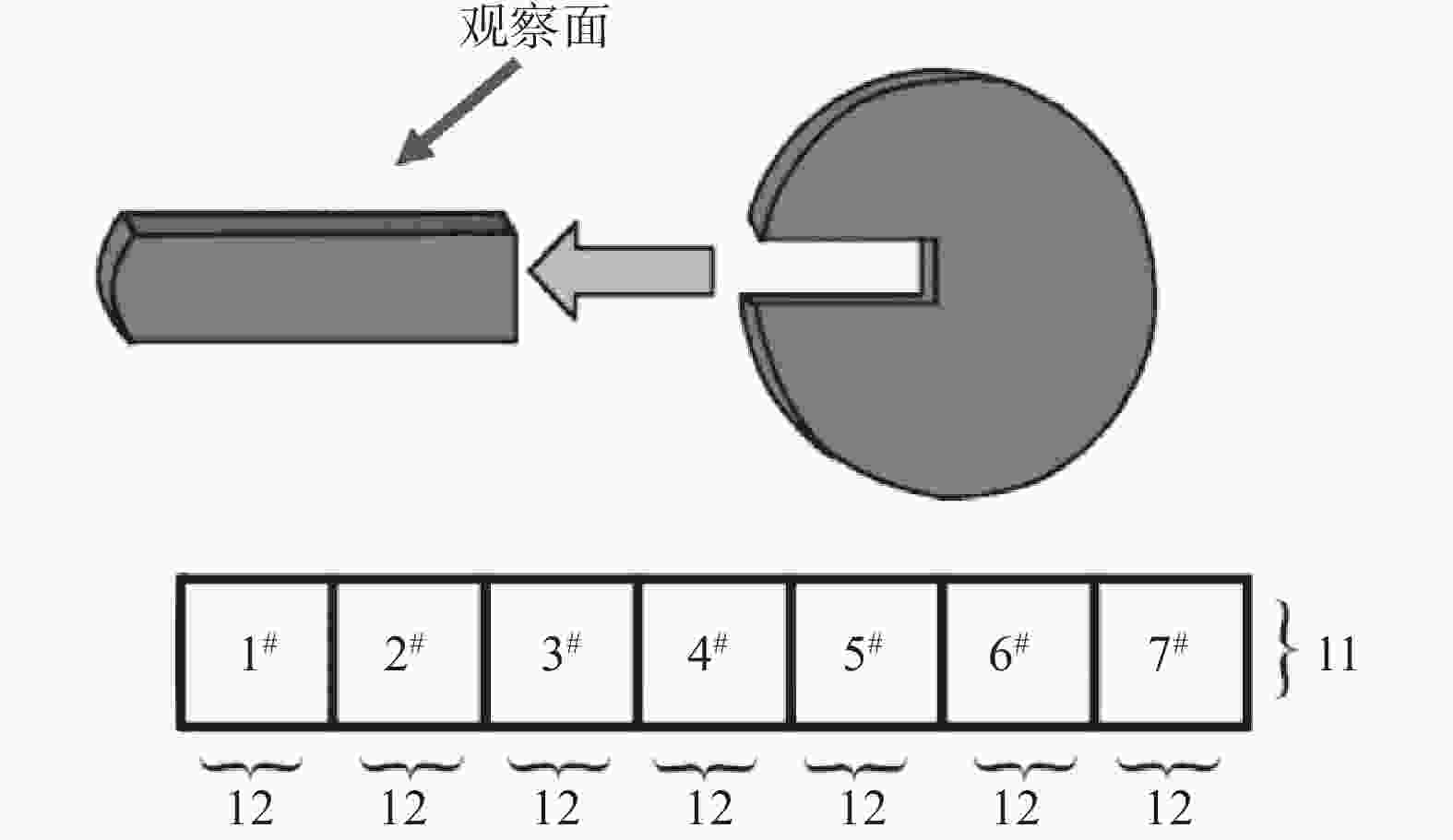

摘要: 使用Factsage热力学软件计算Cr12MoV冷作模具钢中不同相的转变、不同夹杂物和碳化物析出情况,OM与SEM等对模铸坯的夹杂物与碳化物进行解析。研究表明,Cr12MoV钢中主要是不规则稀土复合氧硫化物和硫化物夹杂,具体为Ce2S3、Ce2O2S和La2S3夹杂,而Al2O3和MnS夹杂经过稀土元素的改质后,几乎都以稀土复合氧硫化物和硫化物夹杂形式存在于模铸坯中,夹杂物密度和面积比例分别为102~136个/mm2和0.06%~0.15%,夹杂物等效直径集中分布于2.5~3.0 μm。Cr12MoV冷作模具钢中含有大量碳化物,其类型为富Fe和Cr的M23C6型的共晶碳化物,铸坯心部的碳化物平均等效直径为4.9 μm,边部化物平均等效直径为3.7 μm,从铸坯边部到心部碳化物面积比例为2.94%~4.31%。Abstract: The transformation of different phases, the precipitation of inclusions and carbides in the Cr12MoV cold work die steel were calculated using Factsage thermodynamic software. The inclusions and carbides of the mold casting billets were analyzed using OM and SEM. It is shown that Cr12MoV steel is dominated by irregular rare-earth complex oxygen sulfide and sulfide inclusions, specifically Ce2S3, Ce2O2S and La2S3 inclusions. The Al2O3 and the MnS inclusions exist in the mold-cast billet in the form of rare-earth complex oxygen sulfide and sulfide inclusions after modification by rare earth elements. The density and area ratio of inclusions are 102~136 pieces /mm2 and 0.06%~0.15%, respectively. The equivalent diameters of inclusions are mainly in the range of 2.5~3.0 μm. Cr12MoV cold work mold steel contains a large number of carbides, in which the carbides are Fe-riched and Cr-riched eutectic carbides of M23C6 type. The average equivalent diameter of carbides in the center of billets is 4.9 μm and 3.7 μm at the edge. The area proportion of carbides from the edge to the center of billets ranges from 2.94% to 4.31%.

-

Key words:

- Cr12MoV /

- mold casting billets /

- rare earth /

- inclusions /

- carbides

-

表 1 Cr12MoV钢主要化学成分

Table 1. Main chemical composition of Cr12MoV steel

% C Si Mn P S Cr Mo V La Ce 1.55 0.26 0.30 0.02 0.0025 11.75 0.50 0.25 0.002 0.003 表 2 Cr12MoV钢不同碳化物中的元素成分

Table 2. Energy spectrum composition of typical carbides in Cr12MoV steel

% 能谱点 Fe Cr Mo C P1 54.46 40.52 1.44 6.38 P2 56.76 40.81 1.80 5.64 P3 51.05 40.00 1.23 5.50 P4 53.36 38.74 1.15 5.61 P5 53.54 39.42 1.61 5.43 P6 52.98 42.67 0.63 3.73 P7 53.89 37.50 1.91 5.51 P8 51.62 42.57 2.05 4.96 P9 51.62 40.33 1.94 4.69 -

[1] Du Simin, Li Xiong, Lin Faju. Effect of heat treatment process on microstructure and hardness of Cr12MoV steel[J]. Iron Steel Vanadium Titanium, 2021,42(3):148-154. (杜思敏, 李雄, 林发驹. 热处理工艺对Cr12MoV钢组织及硬度的影响[J]. 钢铁钒钛, 2021,42(3):148-154.Du Simin, Li Xiong, Lin Faju. Effect of heat treatment process on microstructure and hardness of Cr12MoV steel[J]. Iron Steel Vanadium Titanium, 2021, 42(3): 148-154. [2] Zhang Jingguo, Xu Hanbin, Shi Haisheng, et al. Microstructure and properties of spray formed Cr12MoV steel for rolls[J]. Journal of Materials Processing Technology, 2001, 111(1): 79-84. [3] Chen Geng, Miao Jingguo, Fang Qin, et al. Quenching and tempering process of Cr12MoV stee[J]. Modern Salt and Chemical Industry, 2022,49(3):19-21. (陈庚, 苗景国, 方琴, 等. Cr12MoV钢的淬火回火工艺[J]. 现代盐化工, 2022,49(3):19-21.Chen Geng, Miao Jingguo, Fang Qin, et al. Quenching and tempering process of Cr12MoV stee[J]. Modern Salt and Chemical Industry, 2022, 49(3): 19-21. [4] Sun Xiuhua, Liu Ming, Ma Ye, et al. Analysis of heat treatment process and property of Cr12MoV cold work die steel[J]. Mold Materials and Heat Treatment Technology, 2022,22(6):86-88. (孙秀华, 刘明, 马野, 等. Cr12MoV冷作模具钢热处理工艺及性能分析[J]. 模具制造, 2022,22(6):86-88.Sun Xiuhua, Liu Ming, Ma Ye, et al. Analysis of heat treatment process and property of Cr12MoV cold work die steel[J]. Mold Materials and Heat Treatment Technology, 2022, 22(6): 86-88. [5] Wieczerzak K, Bala P, Stepien M, et al. Formation of eutectic carbides in Fe–Cr–Mo–C alloy during non-equilibrium crystallization[J]. Materials & Design, 2016, 94: 61-68. [6] Venkatraman M, Neumann J P. The C-Cr (carbon-chromium) system[J]. Bulletin of Alloy Phase Diagrams, 1990,11(2):152-159. doi: 10.1007/BF02841701 [7] Tao Yong. Effects of heat treatment on microstructure and mechanical property of Cr12MoV[J]. Hot Working Technology, 2014,43(16):201-203. (陶勇. 热处理对Cr12MoV组织和力学性能的影响[J]. 热加工工艺, 2014,43(16):201-203.Tao Yong. Effects of heat treatment on microstructure and mechanical property of Cr12MoV[J]. Hot Working Technology, 2014, 43(16): 201-203. [8] Yang Chaoyun, Luan Yikun, Li Dianzhong, et al. Effects of rare earth elements on inclusions and impact toughness of high-carbon chromium bearing steel[J]. Journal of Materials Science & Technology, 2019,35(7):1298-1308. [9] Xing Zhixiang, Wang Xianxian, Ning Mengshuai, et al. Micromagnetic and robust evaluation of surface hardness in Cr12MoV steel considering repeatability of the instrument[J]. Sensors, 2023,23(3):1273. doi: 10.3390/s23031273 [10] Wang Xigang. Effect of heat treatment on properties of Cr12MoV forging cold working die steel[J]. Hot Working Technology, 2018,47(12):149-152. (王喜刚. 热处理对Cr12MoV锻造冷作模具钢性能的影响[J]. 热加工工艺, 2018,47(12):149-152.Wang Xigang. Effect of heat treatment on properties of Cr12MoV forging cold working die steel[J]. Hot Working Technology, 2018, 47(12): 149-152. [11] Wu Baoye, Liu Peng, Wang Xizhao, et al. Effect of laser absorption on picosecond laser ablation of Cr12MoV mold steel, 9Cr18 stainless steel and H13A cemented carbide[J]. Optics & Laser Technology, 2018,101:11-20. [12] Xu Peiyu, Zhao Zuofu, Zhao Yuqing, et al. Effects of electric pulse assisted nitriding treatment on microstructure and properties of Cr12MoV steel[J]. Hot Working Technology, 2023(22):81-84. (徐培育, 赵作福, 赵宇擎, 等. 电脉冲辅助渗氮处理对Cr12MoV钢组织和性能的影响[J]. 热加工工艺, 2023(22):81-84.Xu Peiyu, Zhao Zuofu, Zhao Yuqing, et al. Effects of electric pulse assisted nitriding treatment on microstructure and properties of Cr12MoV steel[J]. Hot Working Technology, 2023(22): 81-84. [13] Hu Fengrong. Study on wear resistance of Cr12MoV steel and optimization of heat treatment process[J]. Special Steel Technology, 2022,28(2):4-8. (胡峰荣. Cr12MoV钢耐磨性能研究及热处理工艺优化[J]. 特钢技术, 2022,28(2):4-8.Hu Fengrong. Study on wear resistance of Cr12MoV steel and optimization of heat treatment process[J]. Special Steel Technology, 2022, 28(2): 4-8. [14] Gao Zhiyu, He Wei, Jing Xiukun, et al. Failure analysis and heat treatment process optimization of Cr12MoV steel blanking die[J]. Heat Treatment of Metals, 2021,46(3):206-212. (高志玉, 何维, 景秀坤, 等. Cr12MoV钢冲裁模的失效分析与热处理工艺优化[J]. 金属热处理, 2021,46(3):206-212.Gao Zhiyu, He Wei, Jing Xiukun, et al. Failure analysis and heat treatment process optimization of Cr12MoV steel blanking die[J]. Heat Treatment of Metals, 2021, 46(3): 206-212. [15] Hamidzadeh M A, Meratian M, Saatchi A. Effect of cerium and lanthanum on the microstructure and mechanical properties of AISI D2 tool steel[J]. Materials Science and Engineering: A, 2013,571:193-198. doi: 10.1016/j.msea.2013.01.074 [16] Wang Longmei. Role and application prospects of rare earth elements in the new generation of high strength steels[J]. Journal of the Chinese Rare Earth Society, 2004(1):48-54. (王龙妹. 稀土元素在新一代高强韧钢中的作用和应用前景[J]. 中国稀土学报, 2004(1):48-54. doi: 10.3321/j.issn:1000-4343.2004.01.008Wang Longmei. Role and application prospects of rare earth elements in the new generation of high strength steels[J]. Journal of the Chinese Rare Earth Society, 2004(1): 48-54. doi: 10.3321/j.issn:1000-4343.2004.01.008 [17] Liu Beibei, Sun Han, Xu Xiangyu, et al. Effect of Mg content on solidification structure refinement of 21-4N gas valve steel[J]. Shanghai Metals, 2022,44(1):67-73. (刘贝贝, 孙晗, 徐翔宇, 等. Mg含量对21-4N气阀钢凝固组织细化作用的研究[J]. 上海金属, 2022,44(1):67-73.Liu Beibei, Sun Han, Xu Xiangyu, et al. Effect of Mg content on solidification structure refinement of 21-4N gas valve steel[J]. Shanghai Metals, 2022, 44(1): 67-73. [18] Su Mengmeng, Ji Dengping, Yan Daocong, et al. Effect of tellurium on machinability of 303Cu free cutting stainless steel[J]. China Metallurgy, 2023,33(4):65-72. (苏蒙蒙, 季灯平, 严道聪, 等. 碲对303Cu易切削不锈钢切削性能的影响[J]. 中国冶金, 2023,33(4):65-72.Su Mengmeng, Ji Dengping, Yan Daocong, et al. Effect of tellurium on machinability of 303Cu free cutting stainless steel[J]. China Metallurgy, 2023, 33(4): 65-72. [19] Li Gen. Effect of lanthanum on the inclusion, microstructure and mechanical properties of Cr12 steel[D]. Shenyang: Northeastern University, 2013. (李根. 镧对Cr12钢夹杂物、组织及力学性能的影响[D]. 沈阳: 东北大学, 2013.Li Gen. Effect of lanthanum on the inclusion, microstructure and mechanical properties of Cr12 steel[D]. Shenyang: Northeastern University, 2013. [20] Wu B, Liu P, Duan J, et al. Study on picosecond pulse laser ablation of Cr12MoV cold work mold steel[J]. Materials & Design, 2016,110:549-557. [21] Zhu Haoran, Zhou Maohua, Hu Tao, et al. Effect of magnesium on primary carbides and microstructure of H13 steel[J]. Journal of Iron and Steel Research, 2022,34(11):1278-1285. (朱浩然, 周茂华, 胡涛, 等. 镁对H13钢液析碳化物及组织的影响[J]. 钢铁研究学报, 2022,34(11):1278-1285.Zhu Haoran, Zhou Maohua, Hu Tao, et al. Effect of magnesium on primary carbides and microstructure of H13 steel[J]. Journal of Iron and Steel Research, 2022, 34(11): 1278-1285. [22] Gong Lichao, Pan Yongzhi, Peng Chao , et al. Effect of ultrasonic surface rolling processing on wear properties of Cr12MoV steel[J]. Materials Today Communications, 2022, 33: 104762. [23] Chen Guangjun, Hou Shuai, Han Songxi, et al. Optimization of machining parameters and electrochemical corrosion behavior of hardened Cr12MoV mold steel[J]. International Journal of Electrochemical Science, 2020,15(5):3646-3659. doi: 10.20964/2020.05.49 [24] Song Guangjie, Zhu Haoran, Ji Dengping, et al. Analysis of inclusions and carbides in 102Cr17Mo[J]. Iron and Steel, 2023,58(8):157-168. (宋光洁, 朱浩然, 季灯平, 等. 102Cr17Mo轴承钢铸坯夹杂物及碳化物解析[J]. 钢铁, 2023,58(8):157-168.Song Guangjie, Zhu Haoran, Ji Dengping, et al. Analysis of inclusions and carbides in 102Cr17Mo[J]. Iron and Steel, 2023, 58(8): 157-168. [25] Shi Xuehong, Yang Lilin, Xia Ming, et al. Modification effect of rare earth Ce content on inclusions in 4Cr5MoSiV1 steel[J]. Heat Treatment of Metals, 2022,47(11):223-229. (史学红, 杨礼林, 夏明, 等. 稀土Ce含量对4Cr5MoSiV1钢中夹杂物的变质作用[J]. 金属热处理, 2022,47(11):223-229.Shi Xuehong, Yang Lilin, Xia Ming, et al. Modification effect of rare earth Ce content on inclusions in 4Cr5MoSiV1 steel[J]. Heat Treatment of Metals, 2022, 47(11): 223-229. [26] Jin Lei. Study on process of stable control of inclusion in G95Cr18 steel[J]. Special Steel Technology, 2021,27(2):18-21. (金磊. G95Cr18钢夹杂物稳定控制的工艺研究[J]. 特钢技术, 2021,27(2):18-21.Jin Lei. Study on process of stable control of inclusion in G95Cr18 steel[J]. Special Steel Technology, 2021, 27(2): 18-21. [27] Han Jie, Wang Yi, Liu Chengbao, et al. Analysis on modification behavior of rare earth to inclusions in GCr15 bearing stee[J]. Continuous Casting, 2023(2):70-77. (韩杰, 王毅, 刘成宝, 等. 稀土对GCr15轴承钢夹杂物的变质行为分析[J]. 连铸, 2023(2):70-77.Han Jie, Wang Yi, Liu Chengbao, et al. Analysis on modification behavior of rare earth to inclusions in GCr15 bearing stee[J]. Continuous Casting, 2023(2): 70-77. [28] Zhang Dong, Shen Ping, Xie Jianbo, et al. A method for observing tridimensional morphology of sulfide inclusions by non-aqueous solution electrolytic etching[J]. Journal of Iron and Steel Research International, 2019,26(3):10. [29] Pang G X, Li Z L, Chen Z Y. Research on ion nitriding temperature effect on wear resistance of Cr12MoV steel[J]. Physics Procedia, 2013,50:120-123. doi: 10.1016/j.phpro.2013.11.020 [30] Bai Xuxu, Zhang Min, Zeng Jianhua, et al. Analysis of inclusions in the whole process of 20MnCr5 gear steel[J]. Iron Steel Vanadium Titanium, 2022,43(6):143-148. (白旭旭, 张敏, 曾建华, 等. 20MnCr5齿轮钢全流程夹杂物分析[J]. 钢铁钒钛, 2022,43(6):143-148. doi: 10.7513/j.issn.1004-7638.2022.06.021Bai Xuxu, Zhang Min, Zeng Jianhua, et al. Analysis of inclusions in the whole process of 20MnCr5 gear steel[J]. Iron Steel Vanadium Titanium, 2022, 43(6): 143-148. doi: 10.7513/j.issn.1004-7638.2022.06.021 [31] Wu Xiaofeng, Xu Na, Shi Junbo, et al. Control of eutectic carbides in Cr12MoV mold steel and progress in domestic research[J]. Metal Working, 2009(9):72-74. (吴晓峰, 徐娜, 时军波, 等. Cr12MoV模具钢中共晶碳化物的控制及国内研究进展[J]. 金属加工(热加工), 2009(9):72-74.Wu Xiaofeng, Xu Na, Shi Junbo, et al. Control of eutectic carbides in Cr12MoV mold steel and progress in domestic research[J]. Metal Working, 2009(9): 72-74. [32] Huang Hongtao. Study on hot deformation behavior and microstructure-mechanical properties of Cr12MoV steel[D]. Shenyang: Northeastern University, 2009. (黄洪涛. Cr12MoV钢热变形行为及组织性能研究[D]. 沈阳: 东北大学, 2009.Huang Hongtao. Study on hot deformation behavior and microstructure-mechanical properties of Cr12MoV steel[D]. Shenyang: Northeastern University, 2009. -

下载:

下载: