Effect of vanadium on the microstructure and mechanical properties of 7Mn steel during cold rolling process

-

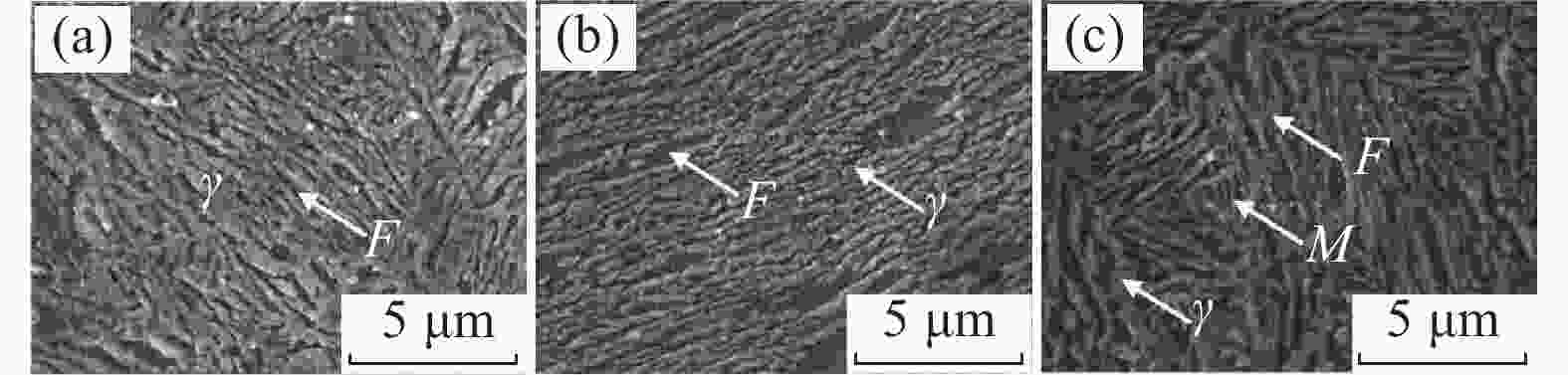

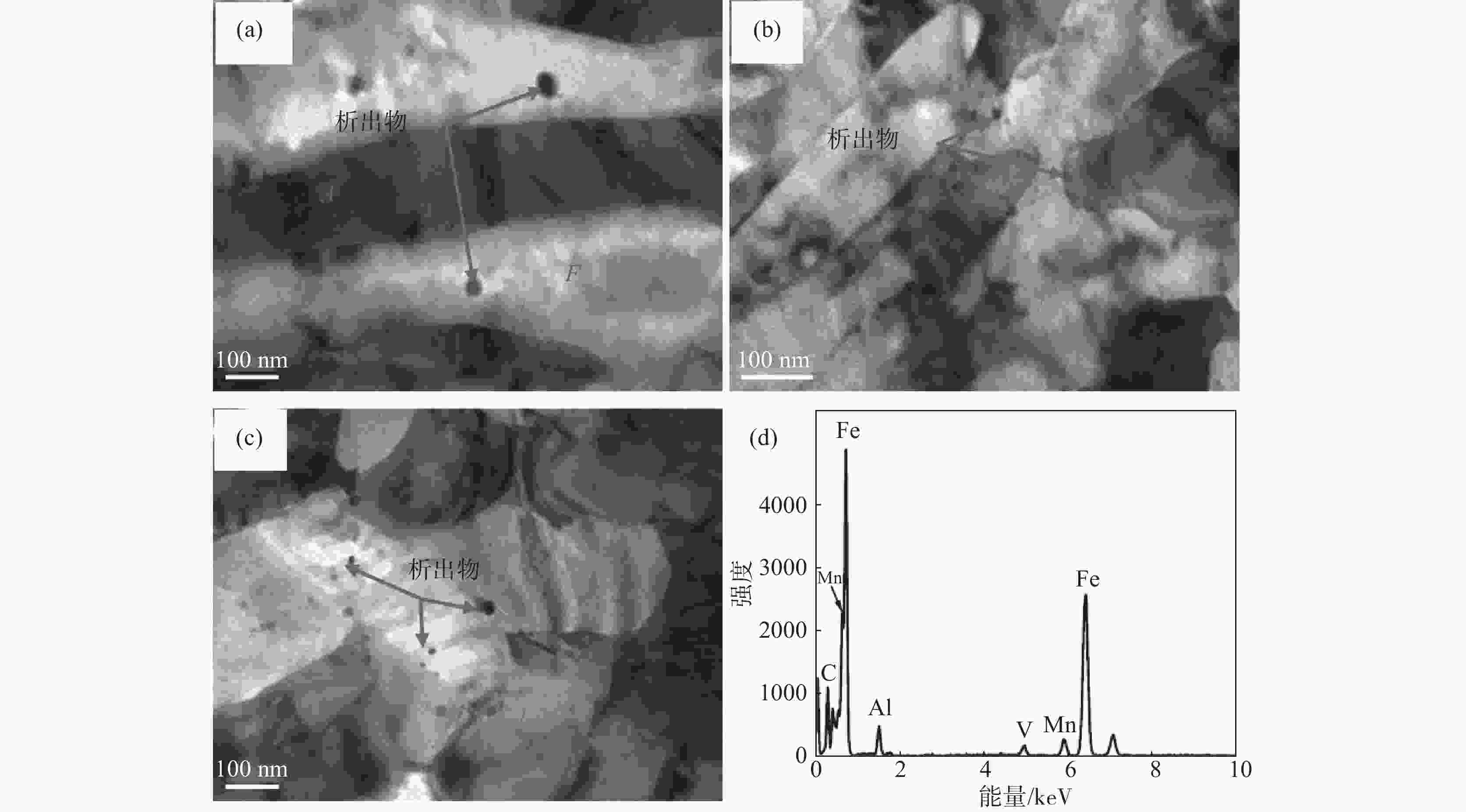

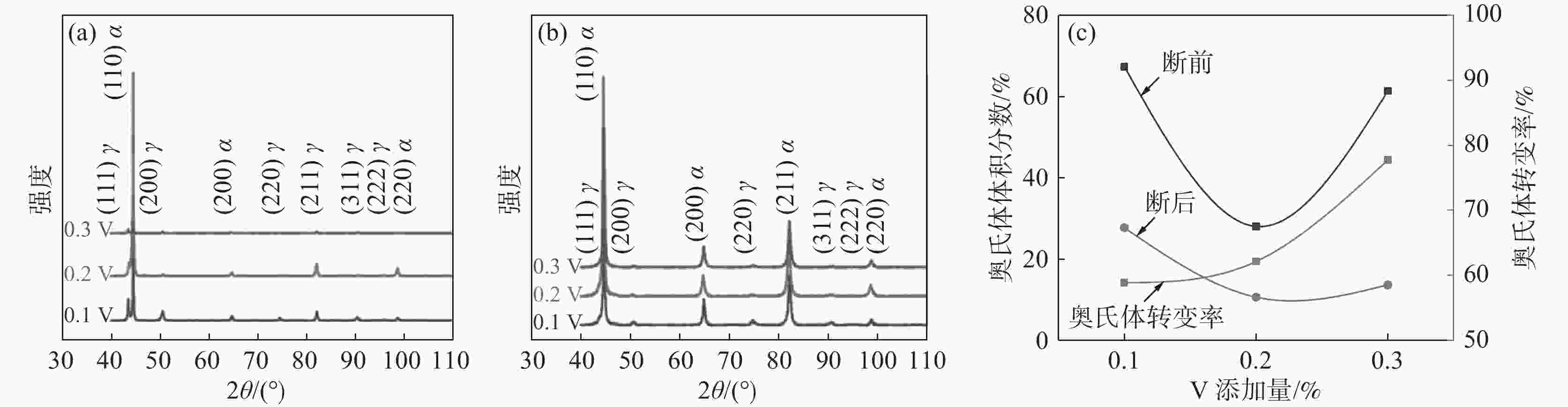

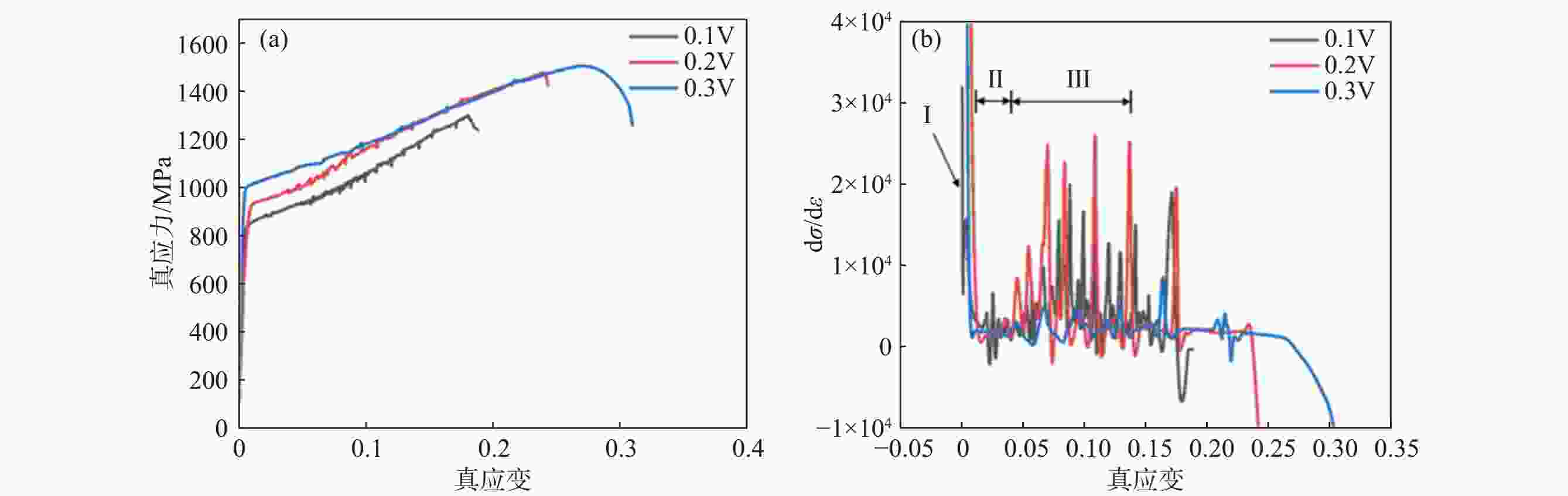

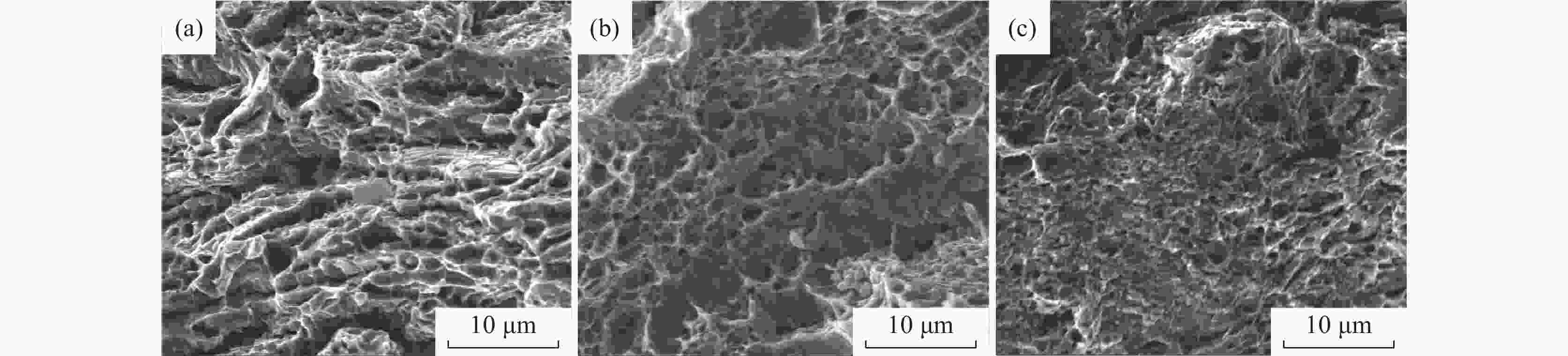

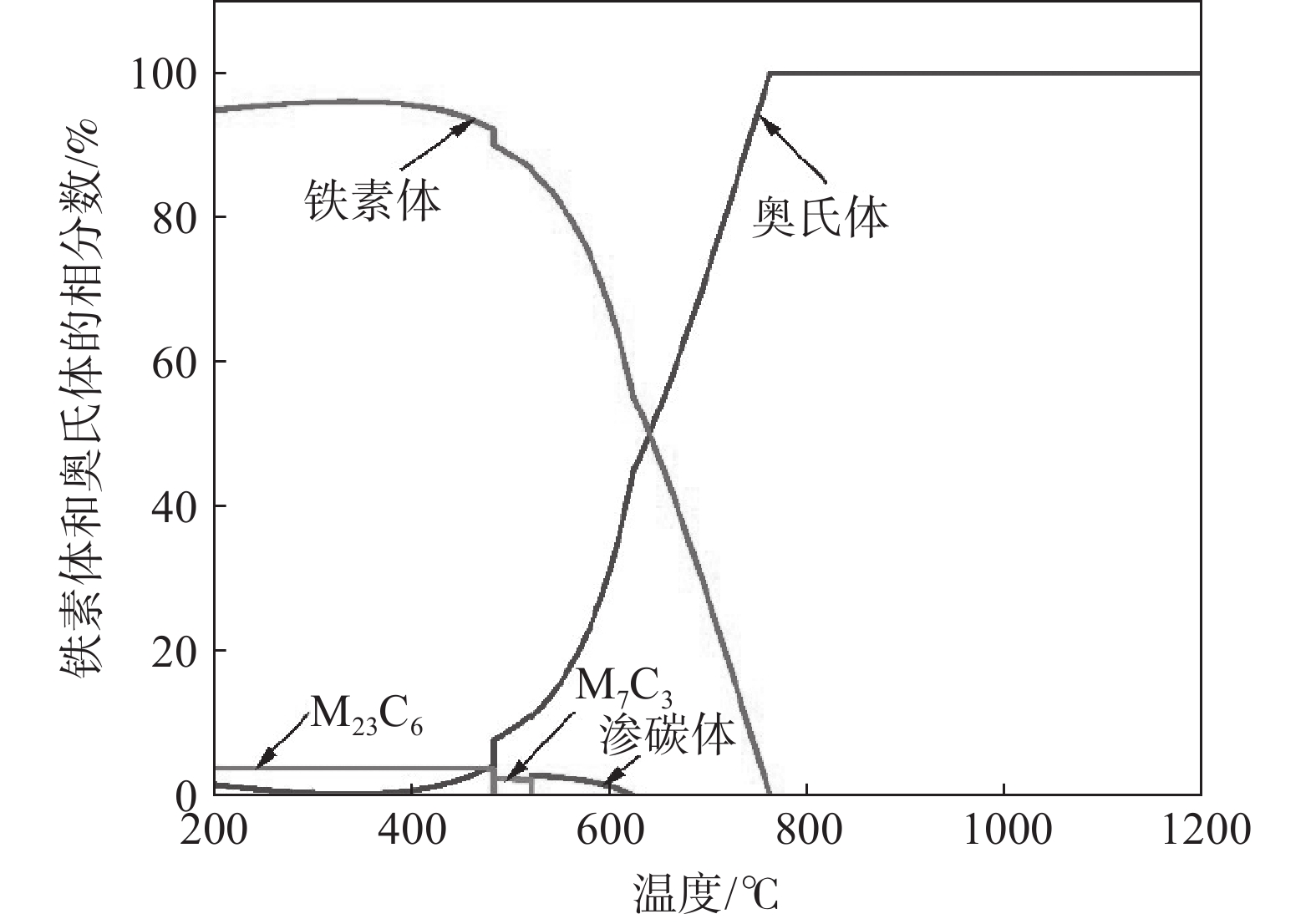

摘要: 在7Mn中锰钢的基础上,向其添加不同含量的V元素,通过冷轧及退火处理,初步探究0.1%~0.3% V添加量对其组织和力学性能的影响规律。结果表明,当V添加量为0.3%时,试验钢的综合力学性能最优,屈服强度为993.96 MPa,抗拉强度为1164.56 MPa,伸长率为37.55%,强塑积为43.73 GPa·%,这是由于V在钢中形成细小弥散的第二相,在细晶强化、第二相强化和TRIP效应的共同作用下提高了试验钢的综合力学性能。Abstract: On the basis of 7Mn medium manganese steel, different contents of V element were added. Through cold rolling and annealing treatment, the influence of 0.1%~0.3% V addition on the microstructure and mechanical properties of the steel was preliminarily explored. The experimental results show that when the content of V is 0.3%, the comprehensive mechanical properties of the experimental steel are the best. The yield strength is 993.96 MPa, with the tensile strength 1164.56 MPa, the elongation 37.55%, and the strength and elongation product 43.73 GPa·%. This is because V forms a fine and dispersed second phase in the steel, which improves the comprehensive mechanical properties of the experimental steel under the combined effects of fine grain strengthening, second phase strengthening and TRIP effect.

-

Key words:

- medium manganese steel /

- V microalloying /

- TRIP effect /

- mechanical properties

-

表 1 试验钢化学成分

Table 1. Chemical compositions of the testing steels

% 编号 V C Mn Al Si Fe 0.1 V 0.06 0.19 7.3 1.10 0.09 余量 0.2 V 0.22 0.19 7.3 1.20 0.04 余量 0.3 V 0.33 0.19 7.3 1.20 0.04 余量 表 2 不同V添加量的7Mn钢的力学性能

Table 2. Mechanical properties of 7Mn steel with different V additions

试验钢 屈服强度/MPa 抗拉强度/MPa 延伸率/% 强塑积/(GPa·%) 0.1 V 818.15 1086.40 26.20 28.46 0.2 V 909.60 1162.84 35.39 41.15 0.3 V 993.96 1164.56 37.55 43.73 -

[1] He B B, Huang X M. Simultaneous increase of both strength and ductility of medium Mn transformation-induced plasticity steel by vanadium alloying[J]. Metallurgical and Materials Transactions A, 2018,49A(5):1433-1438. [2] Lee, Sangwon, Cooman D, et al. Effect of the intercritical annealing temperature on the mechanical properties of 10 Pct Mn multi-phase steel[J]. Metallurgical and Materials Transactions A, 2014,45A(11):5009-5016. [3] Liu L, He B B, Cheng G, et al. Optimum properties of quenching and partitioning steels achieved by balancing fraction and stability of retained austenite[J]. Scripta Materialia, 2018,150:1-6. doi: 10.1016/j.scriptamat.2018.02.035 [4] Li Z, Ding H, Misra R, et al. Microstructure-mechanical property relationship and austenite stability in medium-Mn TRIP steels: The effect of austenite-reverted transformation and quenching-tempering treatments[J]. Materials Science & Engineering: A, 2017(682): 211-219. [5] Jing Songyang, Ding Hua, Liu Mingzhu. Role of Al element in tailoring the austenite mechanical stability and tensile properties of medium Mn steels[J]. Journal of Materials Research and Technology, 2022(20):1414-1427. [6] Li Junkui, Zhang Fucheng. A simultaneously improved strength and ductility on medium Mn TRIP steel designed by pre-twinning strategy based on SFE controlling[J]. Materials Letters, 2022(316):132078. [7] Lee, Seawoong, Estrin, et al. Constitutive modeling of the mechanical properties of V-added medium manganese TRIP steel[J]. Metallurgical and Materials Transactions, 2013,44(7):3136-3146. doi: 10.1007/s11661-013-1648-4 [8] Min T P, Sik M J, Chanwon J, et al. Improved strength of a medium-Mn steel by V addition without sacrificing ductility [J]. Materials Science & Engineering A, 2021, 802:140681. [9] Ye Lan, Wang Junfeng, Zeng Zhaoli, et al. Realization of selective strengthening of ferrite by Nb/V microalloying in a medium carbon lightweight δ-TRIP steel[J]. Metallurgical and Materials Transactions, 2020,51(5):2460-2468. doi: 10.1007/s11661-020-05676-6 [10] Yu Haicun, Cai Zhaochen, Fu Guiqin, et al. Effect of V-Ti addition on microstructure evolution and mechanical properties of hot-rolled transformation-induced plasticity steel[J]. Acta Metallurgica Sinica(English Letters), 2019,32(3):352-360. doi: 10.1007/s40195-018-0796-3 [11] Hu Bin, He Bingbin, Cheng Guanju, et al. Super-high-strength and formable medium Mn steel manufactured by warm rolling process[J]. Acta Materialia, 2019,174:131-141. doi: 10.1016/j.actamat.2019.05.043 [12] Jha B, Avtar R. Structure-property correlation in low carbon low alloy high strength wire rods/wires containing retained austenite[J]. Transactions of the Indian Institute of Metals, 1996,49(3):133-142. [13] Sun B, Fazeli F, Scott C, et al. Microstructural characteristics and tensile behavior of medium manganese steels with different manganese additions[J]. Materials Science & Engineering A, 2018,729:496-507. [14] Cai Z H, Ding H, Xue X, et al. Significance of control of austenite stability and three-stage work-hardening behavior of an ultrahigh strength-high ductility combination transformation-induced plasticity steel[J]. Scripta Materialia, 2013,68(11):865-868. doi: 10.1016/j.scriptamat.2013.02.010 -

下载:

下载: