Low cycle fatigue characteristics and life prediction methods for different regions of 316L welded joints

-

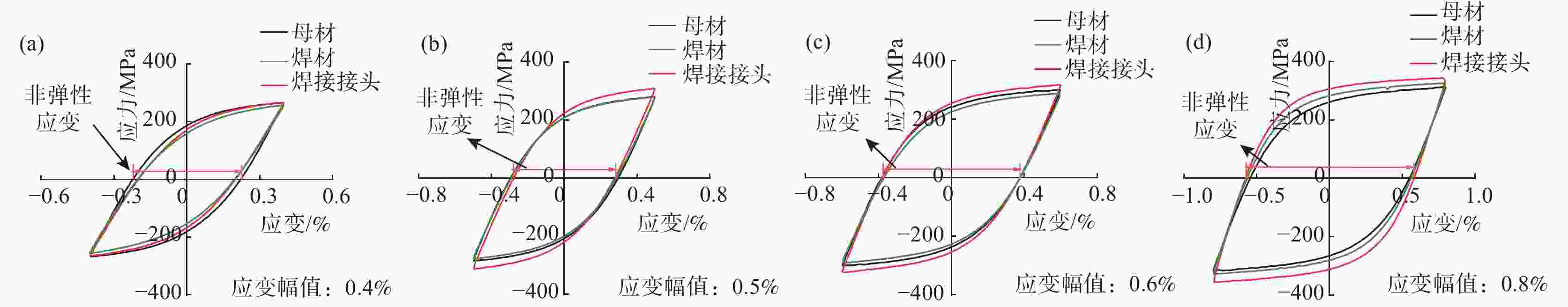

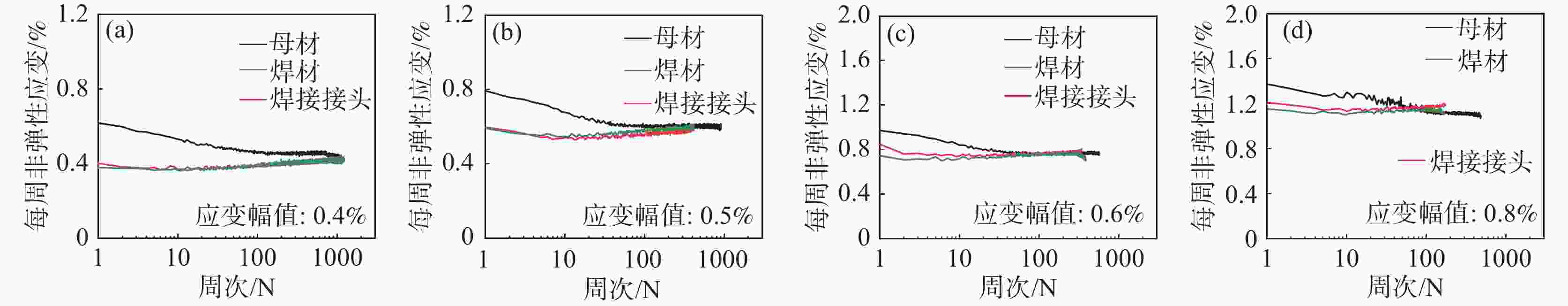

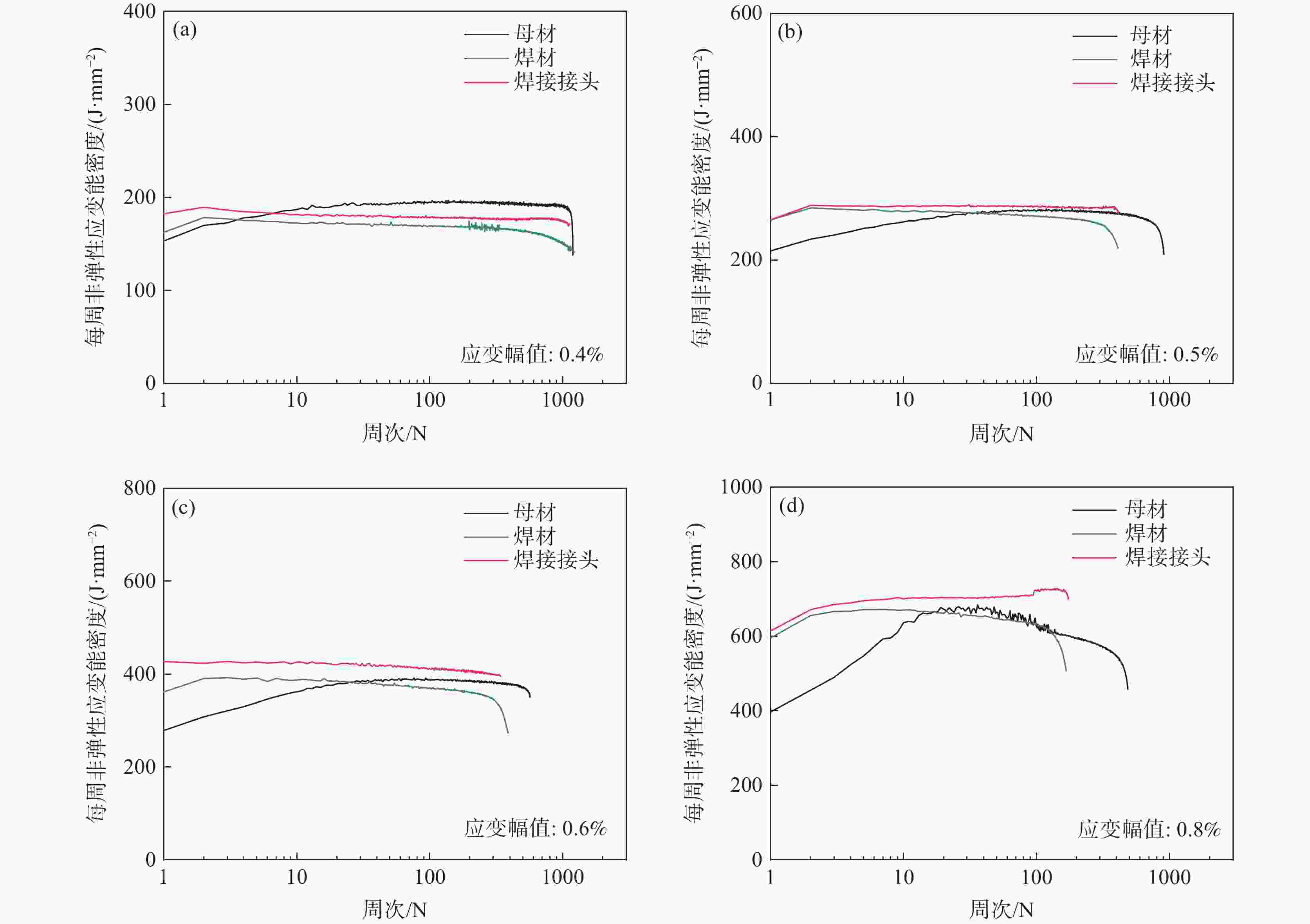

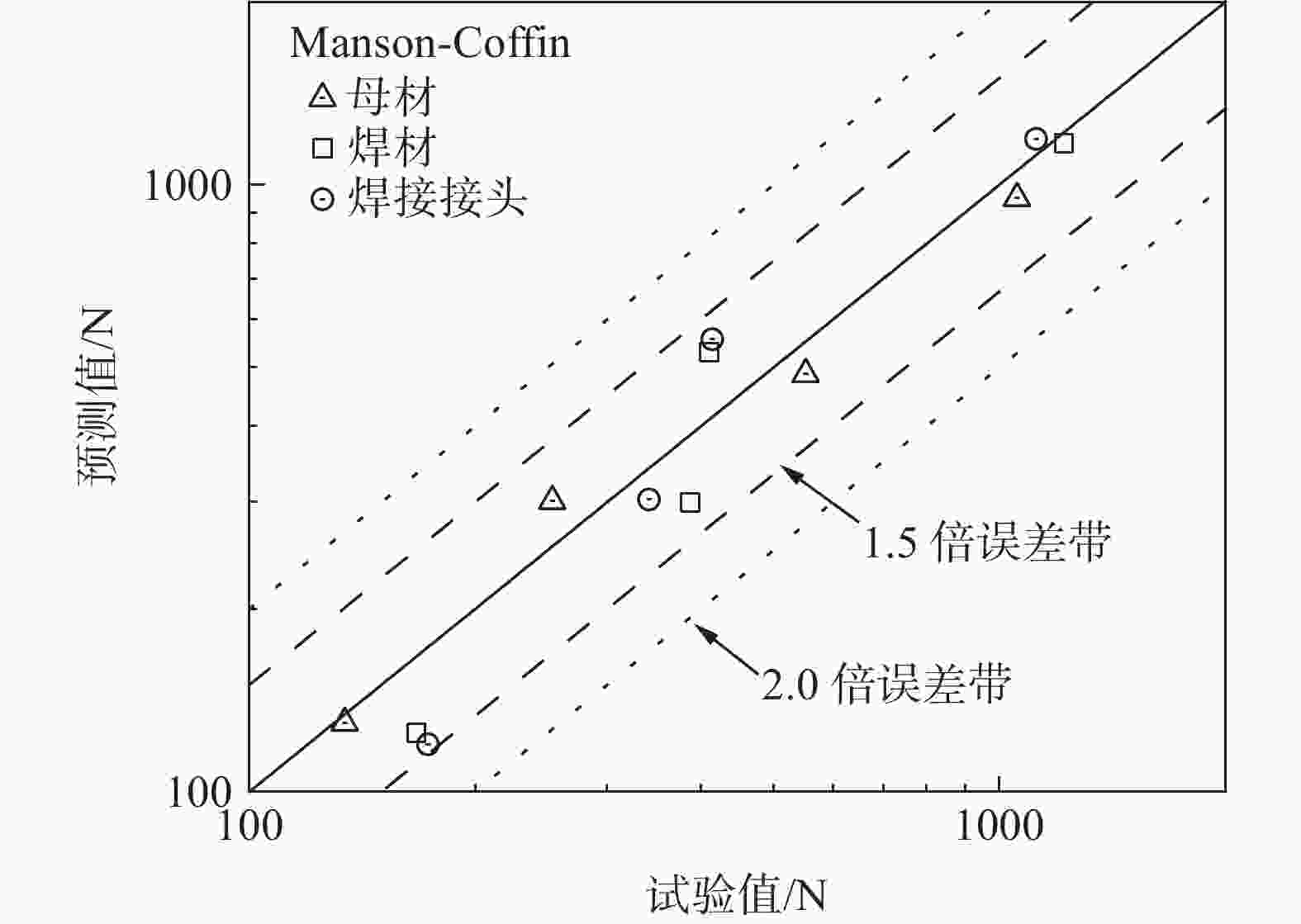

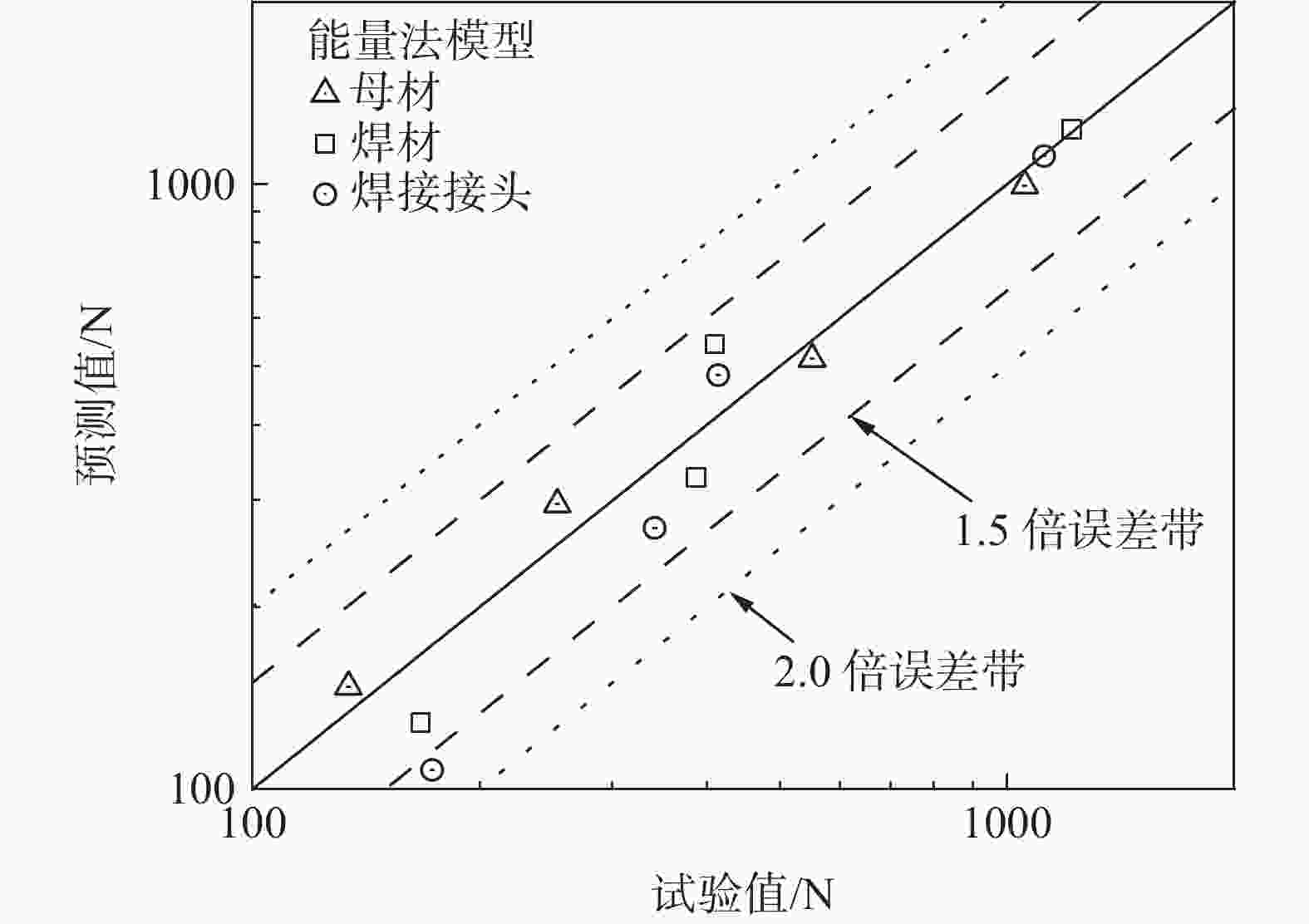

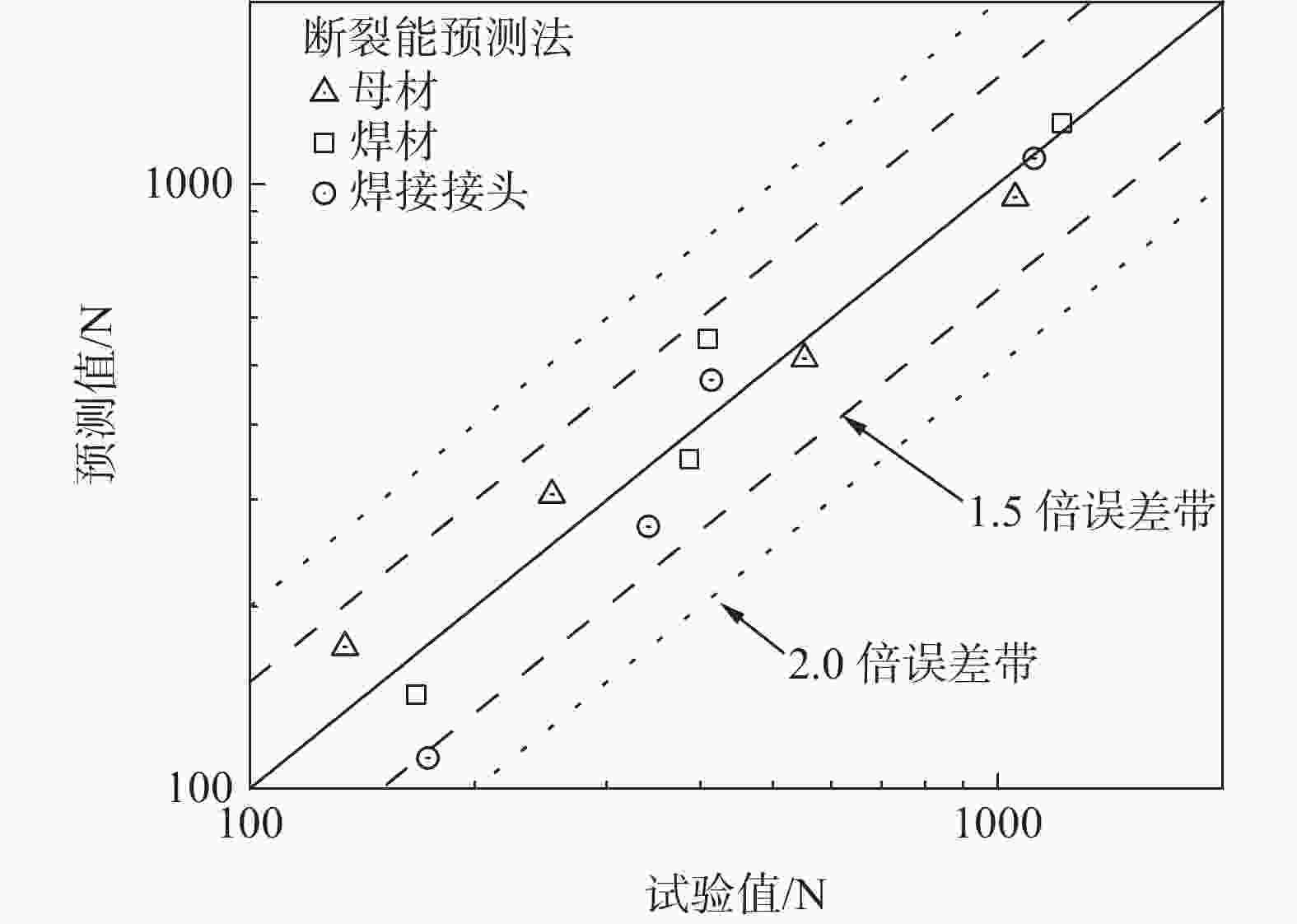

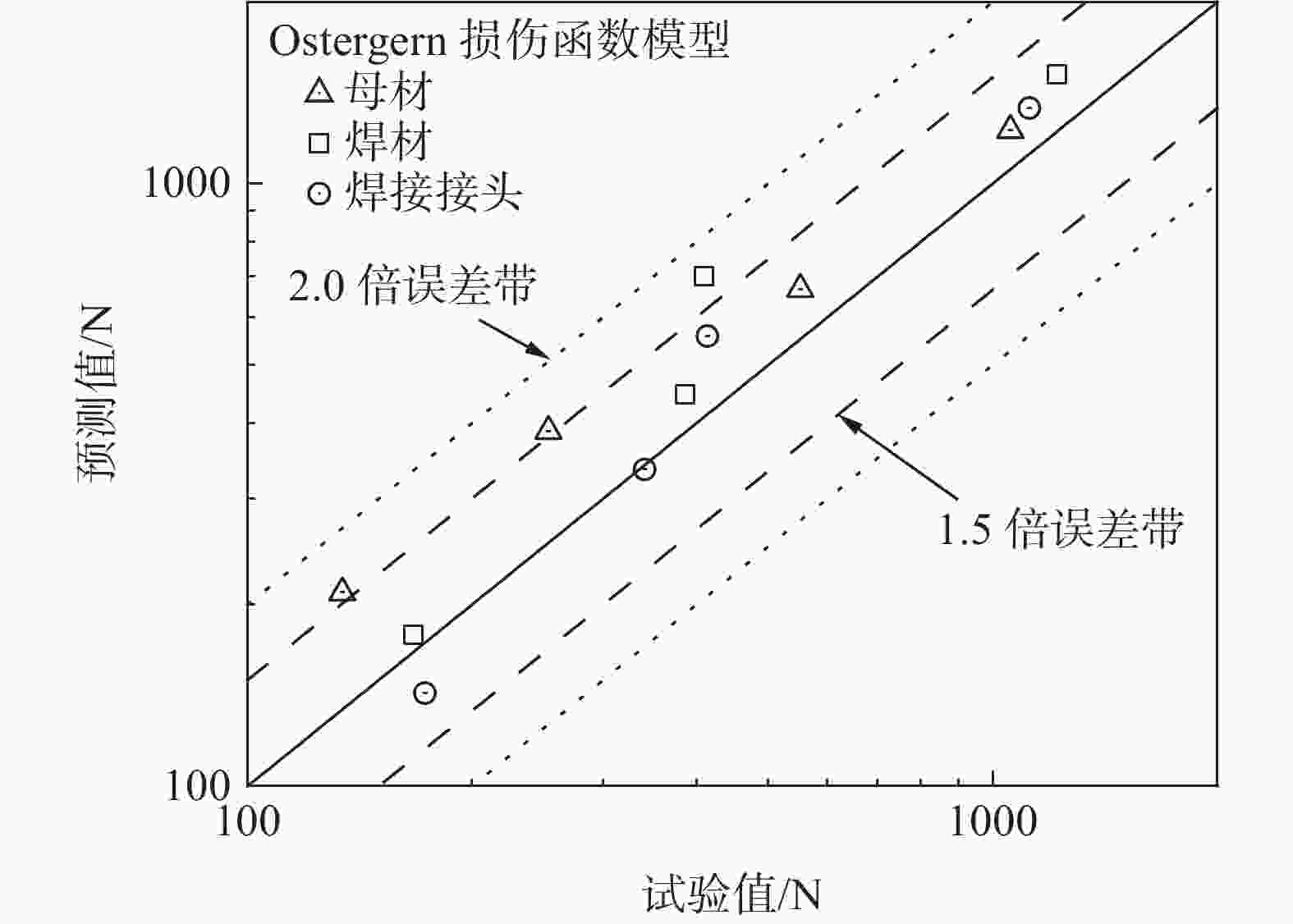

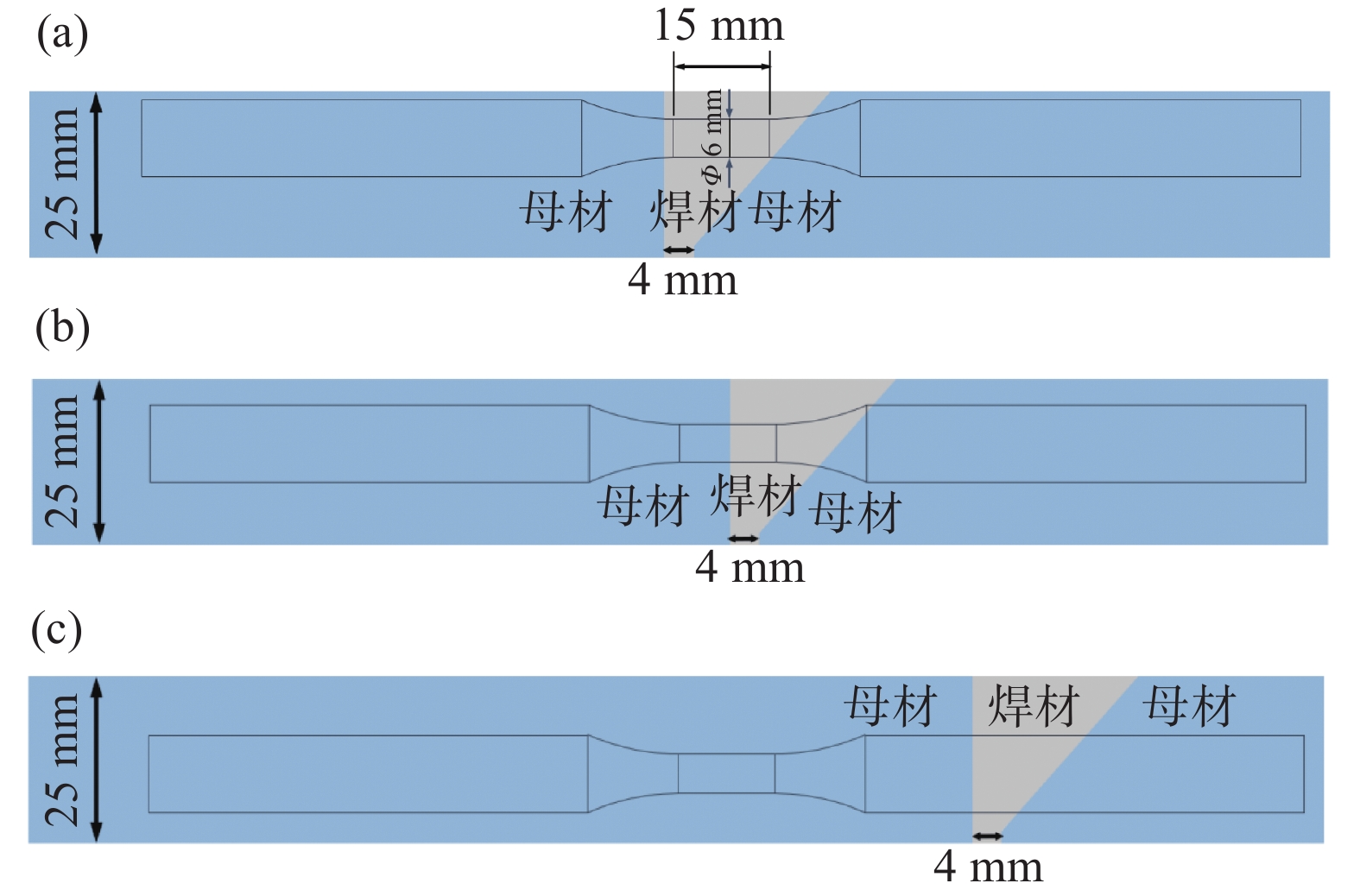

摘要: 系统研究了316L母材、焊材、焊接接头三种试样的高温低周疲劳特性,通过在传统寿命预测模型中引入疲劳寿命减损系数,实现了焊接接头不同区域的低周疲劳寿命预测。结果表明,低周疲劳过程中,三种试样均在初期快速硬化,然后进入稳定循环状态,最后峰值应力快速下降并失效,其中母材硬化持续周次最长,焊材与焊接接头的硬化持续周次相对较短。随着应变幅值的增加,三者的疲劳寿命显著降低,其中母材疲劳寿命明显高于焊材及焊接接头,焊材与焊接接头的疲劳寿命相近。基于母材低周疲劳寿命,采用寿命减损系数对不同材料的低周疲劳寿命进行等效处理,选用多种寿命预测模型对三种试样的等温疲劳寿命进行预测,其中广义应变能损伤函数法在五个模型中表现出最强的适用性。Abstract: In this paper, the high-temperature low-cycle fatigue characteristics of three types of materials: 316L base metal, welded material, and welded joints were systematically studied. By introducing a fatigue life reduction coefficient into the traditional life prediction model, the low-cycle fatigue life prediction of different regions of the welded joints has been achieved. The results show that during the low-cycle fatigue process, all three materials undergo initial rapid hardening, then enter a stable cyclic state, and finally experience a rapid decrease in peak stress followed by failure. Among them, the base metal has the longest duration of hardening, while the hardening duration of the welded material and welded joints is relatively shorter. With the increase of strain amplitude, the fatigue life of the three materials significantly decreases. The fatigue life of the base metal is significantly higher than that of the welded material and welded joints, while the fatigue lifes of the welded material and welded joints are similar. Based on the low-cycle fatigue life of the base metal, the fatigue lifes of different materials are equivalently processed using a life reduction coefficient. Multiple life prediction models are selected to predict and evaluate the isothermal fatigue life of the three materials. It is found out that Generalized Strain Energy Damage Function (GSEDF) method can achieve the best agreement with measured result.

-

Key words:

- 316L /

- welded joint /

- low cycle fatigue /

- life prediction

-

表 1 316L母材和焊材的主要化学成分

Table 1. Main chemical compositions of 316L base metal and weld metal

% 材料 C Cr Ni Mo Mn Si P S 母材 0.018 17.80 12.08 2.23 1.08 0.35 0.019 0.001 焊材 0.020 19.64 13.20 2.33 1.50 0.28 0.014 0.007 表 2 不同应变幅值下316L母材、焊材、焊接接头等温低周疲劳试验方案

Table 2. Isothermal low-cycle fatigue test scheme for 316L base material, welded metal and welded joint under different strain amplitudes

试样编号 温度/ ℃ 应变幅值/% 周期/s BMIF04550 550 ±0.4 80 BMIF05550 550 ±0.5 100 BMIF06550 550 ±0.6 120 BMIF08550 550 ±0.8 160 WJIF04550 550 ±0.4 80 WJIF05550 550 ±0.5 100 WJIF06550 550 ±0.6 120 WJIF08550 550 ±0.8 160 WMIF04550 550 ±0.4 80 WMIF05550 550 ±0.5 100 WMIF06550 550 ±0.6 120 WMIF08550 550 ±0.8 160 -

[1] Stamford L, Azapagic A. Sustainability indicators for the assessment of nuclear power[J]. Energy, 2011,36(10):6037-6057. doi: 10.1016/j.energy.2011.08.011 [2] Zhu Zhiquan, Chen Qian. Opportunities and risks confronted by the development of China’s nuclear power industry and the countermeasures[J]. Journal of East China University of Technology( Social Science), 2017,36(4):318-321. (朱志权, 陈倩. 我国核电产业发展面临的机遇、风险及其对策[J]. 东华理工大学学报(社会科学版), 2017,36(4):318-321.Zhu Zhiquan, Chen Qian. Opportunities and risks confronted by the development of China’s nuclear power industry and the countermeasures[J]. Journal of East China University of Technology( Social Science), 2017, 36(4): 318-321. [3] Fan Y, Liu T G, Xin L, et al. Thermal aging behaviors of duplex stainless steels used in nuclear power plant: A review[J]. Journal of Nuclear Materials, 2021,544:152693. doi: 10.1016/j.jnucmat.2020.152693 [4] Zinkle S J, Was G S. Materials challenges in nuclear energy[J]. Acta Materialia, 2013,61(3):735-758. doi: 10.1016/j.actamat.2012.11.004 [5] Luo Jiong. Influence of environment on fracture toughness and fracture behavior of nuclear safe-end dissimilar metal welded joint[D]. Shenyang: Northeastern University, 2014. (罗炯. 环境对核电接管安全端接头断裂行为及断裂韧性影响[D]. 沈阳: 东北大学, 2014.Luo Jiong. Influence of environment on fracture toughness and fracture behavior of nuclear safe-end dissimilar metal welded joint[D]. Shenyang: Northeastern University, 2014. [6] Li Yifei, Cai Zhipeng, Tang Zhinan, et al. Weak zone shift in welded joints for low cycle fatigue[J]. Journal of Tsinghua University(Science and Technology), 2015,55(10):1056-1060, 1066. (李轶非, 蔡志鹏, 汤之南, 等. 焊接接头低周疲劳性能薄弱区转移[J]. 清华大学学报(自然科学版), 2015,55(10):1056-1060, 1066.Li Yifei, Cai Zhipeng, Tang Zhinan, et al. Weak zone shift in welded joints for low cycle fatigue[J]. Journal of Tsinghua University(Science and Technology), 2015, 55(10): 1056-1060, 1066. [7] Veerababu J, Goyal S, Sandhya R, et al. Low cycle fatigue behaviour of grade 92 steel weld joints[J]. International Journal of Fatigue, 2017,105:60-70. doi: 10.1016/j.ijfatigue.2017.08.013 [8] Veerababu J, Goyal S, Nagesha A. Studies on creep-fatigue interaction behavior of grade 92 steel and its weld joints[J]. International Journal of Fatigue, 2021,149:106307. doi: 10.1016/j.ijfatigue.2021.106307 [9] Farragher T P, Scully S, O'Dowd N P, et al. High temperature, low cycle fatigue characterization of P91 weld and heat affected zone material[J]. Journal of Pressure Vessel Technology, 2014,136(2):021403. doi: 10.1115/1.4025943 [10] Li Haizhou, Chen Jintao, Chen Hui, et al. Cyclic plastic deformation mechanism and cyclic hardening model of sanicro 25 steel welded joint[J]. Materials Science and Engineering: A, 2021,827:141878. doi: 10.1016/j.msea.2021.141878 [11] Rao K B S, Valsan M, Mannan S L. Strain-controlled low-cycle fatigue behavior of type-304 stainless-steel base material, type-308 stainless-steel weld metal and 304-308 stainless-steel weldments[J]. Materials Science & Engineering A, 1990,130(1):67-82. [12] Rao K B S, Sandhya R, Mannan S L. Creep-fatigue interaction behavior of type-308 stainless-steel weld metal and type-304 stainless-steel base-metal[J]. International Journal of Fatigue, 1993,15(3):221-229. doi: 10.1016/0142-1123(93)90180-X [13] Brinkman C, Korth G. Heat-to-heat variations in the fatigue and creep-fatigue behavior of AISI type 304 stainless steel at 593 ℃[J]. Journal of Nuclear Materials, 1973,48(3):293-306. doi: 10.1016/0022-3115(73)90026-3 [14] Brinkman C, Koth G, Beeston J. Comparison of the strain-controlled low cycle fatigue behavior of stainless type 304/308 weld and base material[R]. Idaho Falls, ID, Aerojet Nuclear Co. , 1975. [15] Rao K B S, Valsan M, Sandhya R, et al. Influence of weld discontinuities on strain controlled fatigue behavior of 308 stainless-steel weld metal[J]. Journal of Engineering Materials & Technology, 1994,116(2):193-199. [16] Zhang Yingying, Zhang Xinning, Shi Yu. Microstructure and fracture behavior of 316L stainless steel welded joints under high temperature low cycle[J]. Journal of Materials Science and Engineering, 2019,37(3):501-504. (张莹莹, 张新宁, 师瑀. 316L不锈钢焊接接头高温低周期疲劳显微结构变化和断裂特征[J]. 材料科学与工程学报, 2019,37(3):501-504.Zhang Yingying, Zhang Xinning, Shi Yu. Microstructure and fracture behavior of 316L stainless steel welded joints under high temperature low cycle[J]. Journal of Materials Science and Engineering, 2019, 37(3): 501-504. [17] Li Mingna, Liu Feng. Effect of tensile dwell on low cycle fatigue cyclic stress response and damage mechanism of 316L austenitic stainless steel welding joint[J]. Transactions of the China Welding Institution, 2014,35(9):87-91, 95. (李明娜, 刘峰. 拉保持对316L奥氏体不锈钢焊接接头低周疲劳循环应力响应及损伤机制的影响[J]. 焊接学报, 2014,35(9):87-91, 95.Li Mingna, Liu Feng. Effect of tensile dwell on low cycle fatigue cyclic stress response and damage mechanism of 316L austenitic stainless steel welding joint[J]. Transactions of the China Welding Institution, 2014, 35(9): 87-91, 95. [18] Li Mingna, Liu Feng, Yu Hongmiao. Effect of post weld heat treatment on δ-ferrite structure and properties of 308L weldment stainless steel[J]. Hot Working Technology, 2013,42(9):9-11. (李明娜, 刘峰, 于洪淼. 焊后热处理对308L不锈钢焊缝δ-铁素体形态及性能的影响[J]. 热加工工艺, 2013,42(9):9-11.Li Mingna, Liu Feng, Yu Hongmiao. Effect of post weld heat treatment on δ-ferrite structure and properties of 308L weldment stainless steel[J]. Hot Working Technology, 2013, 42(9): 9-11. [19] Kumar T S, Nagesha A, Kumar J G, et al. Influence of thermal aging on tensile and low cycle fatigue behavior of type 316LN austenitic stainless steel weld joint[J]. Metallurgical and Materials Transactions A, 2018,49a(8):3257-3273. [20] Pham M S, Holdsworth S R. Dynamic strain ageing of AISI 316L during cyclic loading at 300 degrees C: Mechanism, evolution, and its effects[J]. Materials Science and Engineering: A, 2012,556:122-133. doi: 10.1016/j.msea.2012.06.067 [21] Mohyla, Kubon P, Cep Z, et al. Evaluation of creep properties of steel P92 and its welded joint[J]. Metalurgija, 2014,53(2):175-178. [22] Coffin L. Predictive parameters and their application to high-temperature, low-cycle fatigue[J]. Fracture London Chapman & Hall, 1969: 643-654. [23] Wen Jianbin, Zhou Changyu, Li Xin, et al. Effect of temperature range on thermal-mechanical fatigue properties of P92 steel and fatigue life prediction with a new cyclic softening model[J]. International Journal of Fatigue, 2019,129:105226. doi: 10.1016/j.ijfatigue.2019.105226 [24] Zhu Shunpeng, Huang Hongzhong, He Liping, et al. Improved generalized strain energy damage function method for high temperature low cycle fatigue-creep[J]. Acta Aeronautica et Astronautica Sinica, 2011,32(8):1445-1452. (朱顺鹏, 黄洪钟, 何俐萍, 等. 高温低周疲劳-蠕变的改进型广义应变能损伤函数方法[J]. 航空学报, 2011,32(8):1445-1452.Zhu Shunpeng, Huang Hongzhong, He Liping, et al. Improved generalized strain energy damage function method for high temperature low cycle fatigue-creep[J]. Acta Aeronautica et Astronautica Sinica, 2011, 32(8): 1445-1452. [25] Zhu S P, Huang H Z. A generalized frequency separation-strain energy damage function model for low cycle fatigue-creep life prediction[J]. Fatigue & Fracture of Engineering Materials & Structures, 2010,33(4):227-237. [26] Wang Xiaowei, Zhang Wei, Zhang Tianyu, et al. A new empirical life prediction model for 9%–12% Cr steels under low cycle fatigue and creep fatigue interaction loadings[J]. Metals, 2019,9(2):183. doi: 10.3390/met9020183 [27] Nagae Y. Evaluation of creep-fatigue life based on fracture energy for modified 9Cr-1Mo steel[J]. Materials Science & Engineering A: Structural Materials Properties Microstructure & Processing, 2013,560:752-758. [28] Nagae Y, Takaya S, Asayama T. Creep-fatigue evaluation by hysteresis energy in modified 9Cr-1Mo steel[J]. Journal of Solid Mechanics and Materials Engineering, 2009,3(3):449-456. doi: 10.1299/jmmp.3.449 [29] Yin Peng, Zhang Wei, Guo Shen, et al. Thermomechanical fatigue behaviour and damage mechanisms in a 9% Cr steel: Effect of strain rate[J]. Materials Science and Engineering: A, 2021,815:141308. doi: 10.1016/j.msea.2021.141308 -

下载:

下载: