Progress of laser additive manufactured high-performance metal structural materials

-

摘要: 高性能金属构件激光增材制造技术在重大高端装备制造中展现出巨大发展潜力和广阔的应用前景,北京航空航天大学在大型金属构件激光增材制造方面开展了深入研究,取得了许多突破性研究成果。文中综述了该团队在高性能金属结构材料激光增材制造技术方面的研究进展,揭示了激光增材制造非平衡凝固形核生长机理,建立了钛合金和镍基高温合金晶粒形态主动控制方法,提出了激光增材制造材料强韧化新机理,开发出高性能增材制造钛合金和超高强度钢。未来研究热点仍聚焦于激光/金属交互作用行为、材料凝固相变规律等基础问题研究,以及基于激光增材超常冶金的高性能全新金属结构材料设计与开发,以进一步发挥激光增材制造技术在国家重大装备大型金属构件制造方面的变革性潜力。Abstract: Laser additive manufacturing technology on high-performance metallic components has shown great potential and broad application prospects in the manufacturing of key equipment. Beihang University has conducted deep research on laser additive manufactured large metallic components and achieved many research breakthroughs. In this article, the progress of laser additive manufactured high-performance metal structural materials was summarized. The non-equilibrium solidification and nucleation growth behavior were revealed, and the active control method on grain morphologies of titanium alloys and nickel-based superalloys was established. Besides, new strengthening and toughening mechanisms for laser additive manufactured materials were proposed, while titanium alloy and ultra-high strength steel specially for additive manufacturing were developed. Future research interests will continue to focus on fundamental issues such as laser/metal interaction behavior, material solidification and phase transition laws, as well as the design and development of high-performance new alloys based on extreme metallurgical conditions of laser additive manufacturing. Thus, the transformative potential of laser additive manufacturing technology in the manufacturing of large metal components for key equipments can be further unleashed.

-

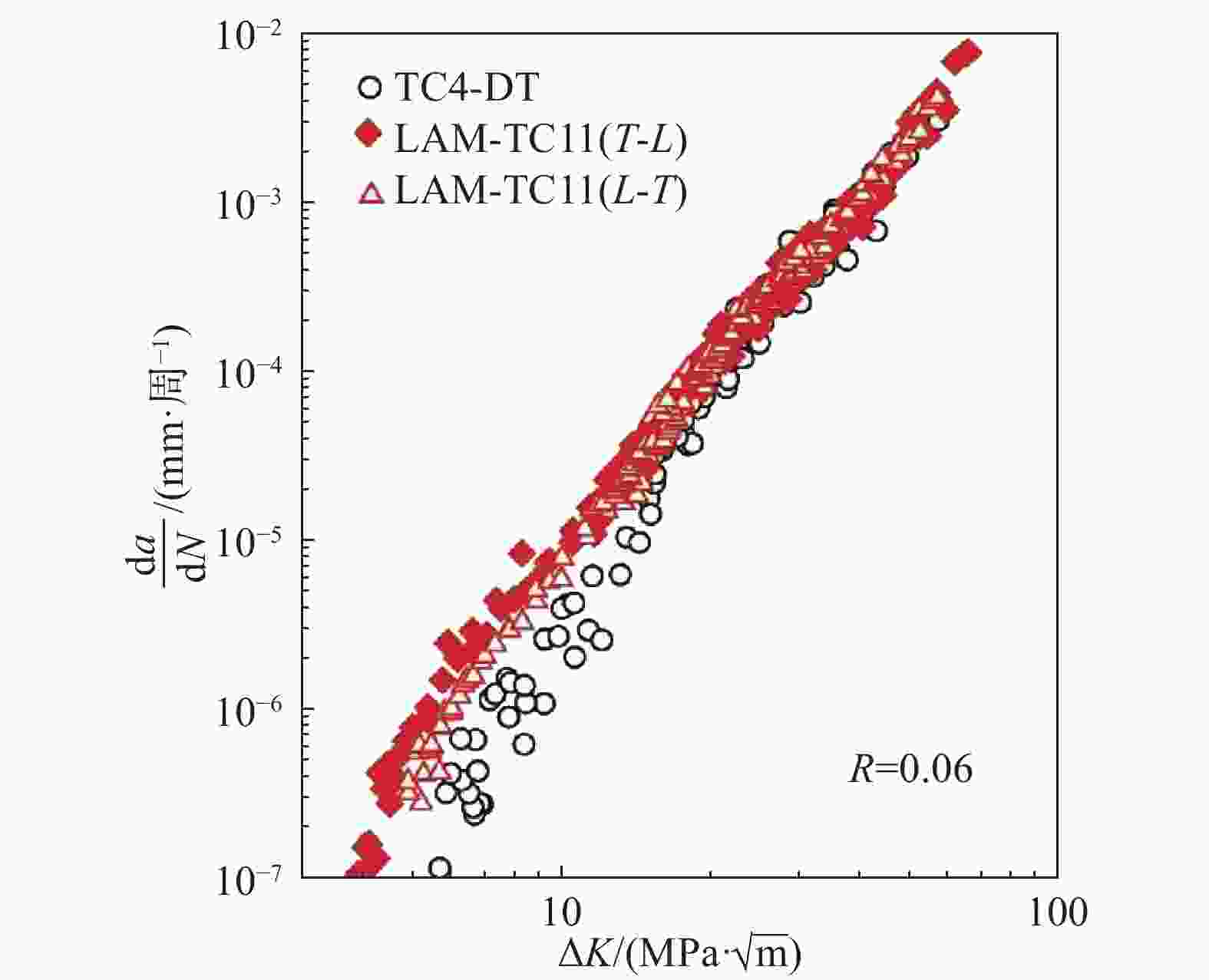

图 5 LAM-TC11与锻件TC4-DT钛合金的疲劳裂纹扩展速率相当[16]

Figure 5. Comparison of fatigue crack growth rate of LAM-TC11 titanium alloy and forged TC4-DT

表 1 LAM-TC11、TC11锻件、TC4-DT和TC4钛合金强度和断裂韧性对比[16]

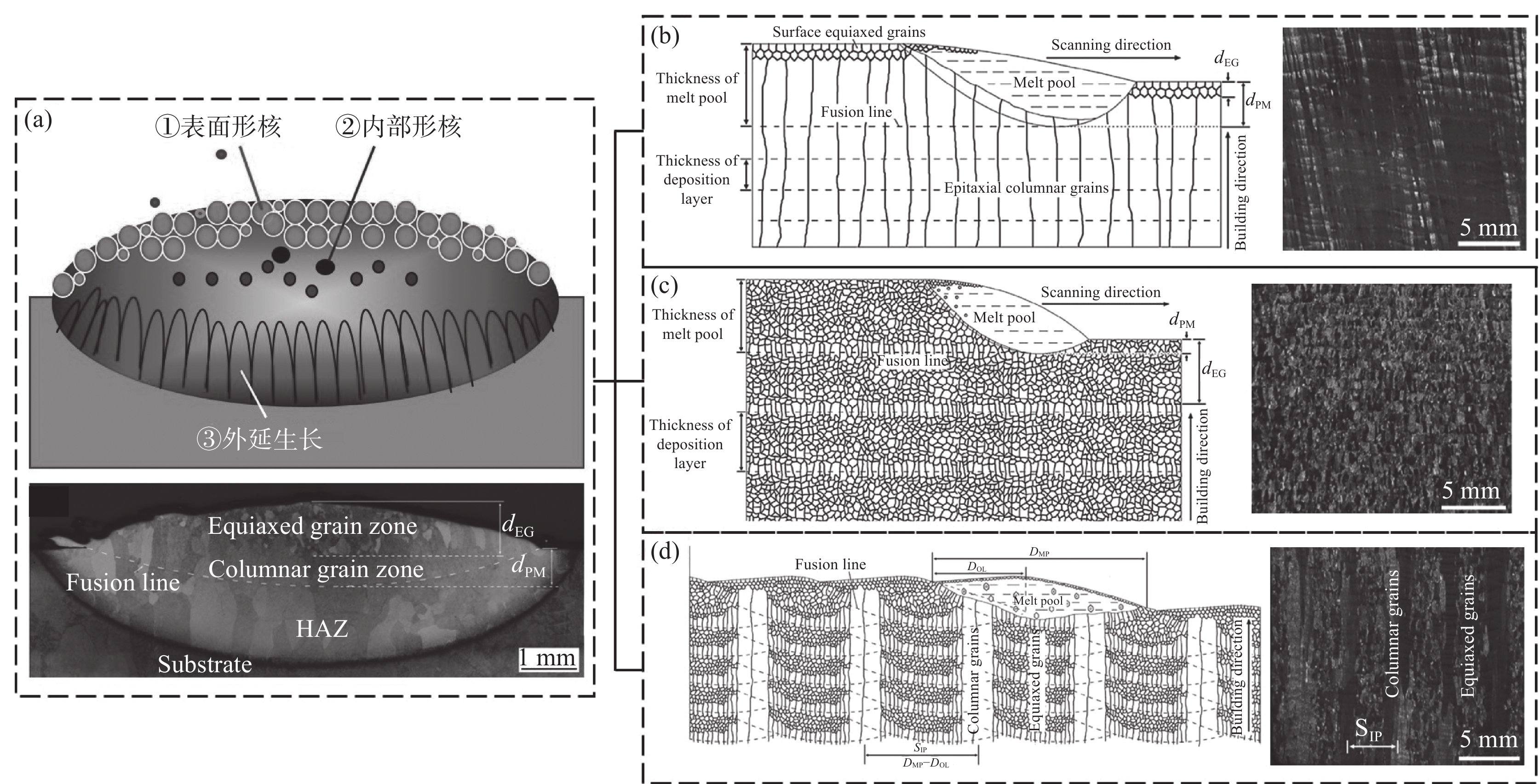

Table 1. Comparison of ultimate strength and fracture toughness of LAM-TC11, forged TC11, TC4-DT and TC4 titanium alloys[16]

试样 极限强度

σb/MPa屈服强度

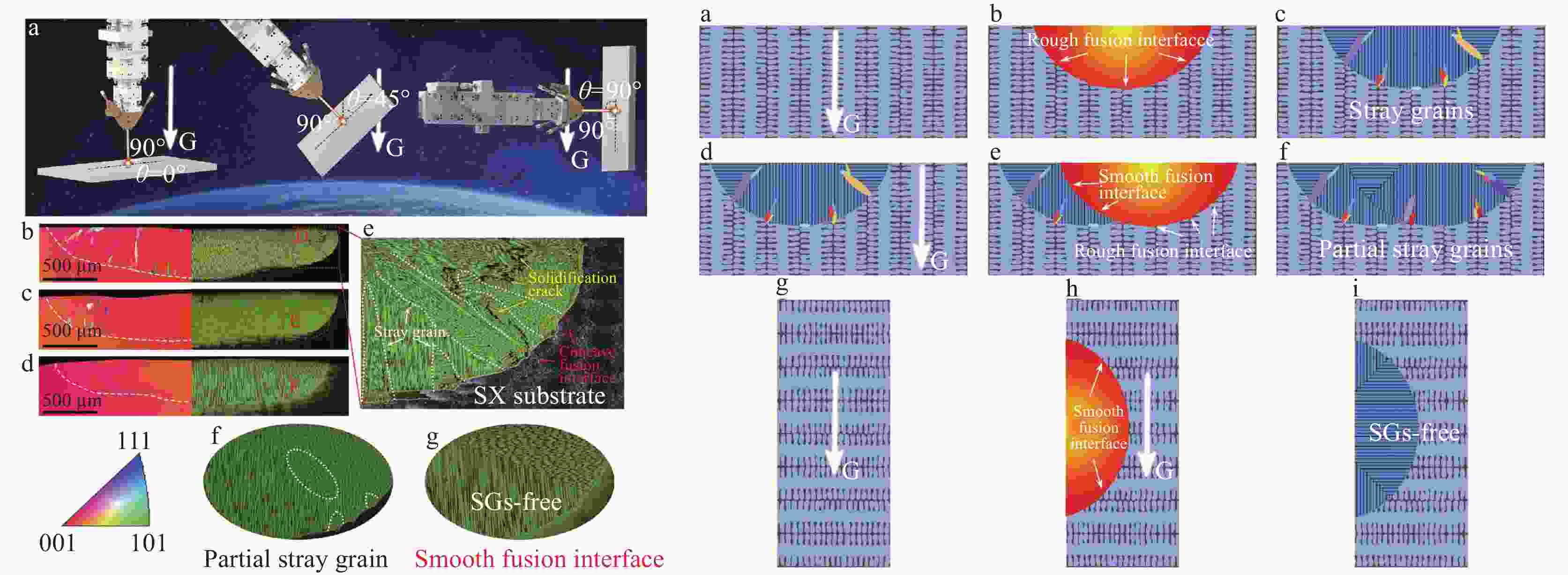

σ0.2/MPa断裂韧性

KIC/(MPa·m1/2)屈强比

σ0.2/σb(KIC/σb)/(mm)1/2 许用应力

[σ]=(σb/1.5)/MPa(KIC/σ0.2)2/mm LAM-TC11 1056 902 116 0.85 3.47 704 16.54 TC11锻件 1076 980 76 0.91 2.23 717 6.01 TC4-DT(锻造) 858 794 106 0.93 3.92 572 17.82 TC4(锻造) 922 885 64 0.96 2.19 614 5.23 -

[1] Arcella F G, Froes F H. Producing titanium aerospace components from powder using laser forming[J]. JOM, 2000,52(5):28-30. doi: 10.1007/s11837-000-0028-x [2] Wang Huaming. Materials’ fundamental issues of laser additive manufacturing for high-performance large metallic components[J]. Acta Aeronautica et Astronautica Sinica, 2014,35(10):2690-2698. (王华明. 高性能大型金属构件激光增材制造: 若干材料基础问题[J]. 航空学报, 2014,35(10):2690-2698.Wang Huaming. Materials’ fundamental issues of laser additive manufacturing for high-performance large metallic components[J]. Acta Aeronautica et Astronautica Sinica, 2014, 35(10): 2690-2698. [3] Wang Xiangming, Su Yadong, Wu Bin. Application of additive manufacturing technology on aircraft structure development[J]. Aeronautical Manufacturing Technology, 2014(22):16-20. (王向明, 苏亚东, 吴斌. 增材技术在飞机结构研制中的应用[J]. 航空制造技术, 2014(22):16-20. doi: 10.3969/j.issn.1671-833X.2014.22.002Wang Xiangming, Su Yadong, Wu Bin. Application of additive manufacturing technology on aircraft structure development[J]. Aeronautical Manufacturing Technology, 2014(22): 16-20. doi: 10.3969/j.issn.1671-833X.2014.22.002 [4] Lu Bingheng. Additive manufacturing——Current situation and future[J]. China Mechanical Engineering, 2020,31(1):19-23. (卢秉恒. 增材制造技术——现状与未来[J]. 中国机械工程, 2020,31(1):19-23. doi: 10.3969/j.issn.1004-132X.2020.01.003Lu Bingheng. Additive manufacturing——Current situation and future[J]. China Mechanical Engineering, 2020, 31(1): 19-23. doi: 10.3969/j.issn.1004-132X.2020.01.003 [5] Tang Haibo, Wu Ning, Zhang Shuquan, et al. Research status and development trend of high performance large metallic components by laser additive manufacturing technique[J]. Journal of Netshape Forming Engineering, 2019,11(4):58-63. (汤海波, 吴宇, 张述泉, 等. 高性能大型金属构件激光增材制造技术研究现状与发展趋势[J]. 精密成形工程, 2019,11(4):58-63. doi: 10.3969/j.issn.1674-6457.2019.04.008Tang Haibo, Wu Ning, Zhang Shuquan, et al. Research status and development trend of high performance large metallic components by laser additive manufacturing technique[J]. Journal of Netshape Forming Engineering, 2019, 11(4): 58-63. doi: 10.3969/j.issn.1674-6457.2019.04.008 [6] Gu Dongdong, Zhang Hongmei, Chen Hongyu, et al. Laser additive manufacturing of high-performance metallic aerospace components[J]. Chinese Journal of Lasers, 2020,47(5):32-55. (顾冬冬, 张红梅, 陈洪宇, 等. 航空航天高性能金属材料构件激光增材制造[J]. 中国激光, 2020,47(5):32-55.Gu Dongdong, Zhang Hongmei, Chen Hongyu, et al. Laser additive manufacturing of high-performance metallic aerospace components[J]. Chinese Journal of Lasers, 2020, 47(5): 32-55. [7] Wang Huaming, Zhang Shuquan, Wang Tao, et al. Progress on solidification grain morphology and microstructure control of laser additively manufactured large titanium components[J]. Journal of Xihua University(Natural Science Edition), 2018,37(4):9-14. (王华明, 张述泉, 王韬, 等. 激光增材制造高性能大型钛合金构件凝固晶粒形态及显微组织控制研究进展[J]. 西华大学学报(自然科学版), 2018,37(4):9-14. doi: 10.3969/j.issn.1673-159X.2018.04.002Wang Huaming, Zhang Shuquan, Wang Tao, et al. Progress on solidification grain morphology and microstructure control of laser additively manufactured large titanium components[J]. Journal of Xihua University(Natural Science Edition), 2018, 37(4): 9-14. doi: 10.3969/j.issn.1673-159X.2018.04.002 [8] Wang T, Zhu Y Y, Zhang S Q, et al. Grain morphology evolution behavior of titanium alloy components during laser melting deposition additive manufacturing[J]. Journal of Alloy and Compounds, 2015,632:505-513. doi: 10.1016/j.jallcom.2015.01.256 [9] Zhu Yanyan, Tang Haibo, Li Zhuo, et al. Solidification behavior and grain morphology of laser additive manufacturing titanium alloys[J]. Journal of Alloy and Compounds, 2019,777:712-716. doi: 10.1016/j.jallcom.2018.11.055 [10] Liang Yaojian, Cheng Xu, Li Jia, et al. Microstructural control during laser additive manufacturing of single-crystal nickel-base superalloys: New processing–microstructure maps involving powder feeding[J]. Materials & Design, 2017,130:197-207. [11] Wang Jiawei, Wang Huaming, Li Kangjie, et al. A new strategy to inhibit stray grain formation during laser directed solidification of single crystal superalloys[J]. Journal of Alloy and Compounds, 2022,906:163852. doi: 10.1016/j.jallcom.2022.163852 [12] Wang Jiawei, Wang Huaming, Gao Hongwei, et al. Crystal growth for different substrate orientations during laser directed solidification of single crystal superalloys[J]. Journal of Alloy and Compounds, 2023,957:170219. doi: 10.1016/j.jallcom.2023.170219 [13] Zhu Yanyan, Li Jia, Tian Xiangjun, et al. Microstructure and mechanical properties of hybrid fabricated Ti-6.5Al-3.5Mo-1.5Zr-0.3Si titanium alloy by laser additive manufacturing[J]. Materials Science and Engineering A, 2014,607:427-434. doi: 10.1016/j.msea.2014.04.019 [14] Zhu Yanyan, Liu Dong, Tian Xiangjun, et al. Characterization of microstructure and mechanical properties of laser melting deposited Ti-6.5Al-3.5Mo-1.5Zr-0.3Si titanium alloy[J]. Materials and Design, 2014,56:445-453. doi: 10.1016/j.matdes.2013.11.044 [15] Wang Yafei, Chen Rui, Cheng Xu, et al. Effects of microstructure on fatigue crack propagation behavior in a bi-modal TC11 titanium alloy fabricated via laser additive manufacturing[J]. Journal of Materials Science & Technology, 2019,35:403-408. [16] Zhang Jikui, Kong Xiangyi, Ma Shaojun, et al. Laser additive manufactured high strength-toughness TC11 titanium alloy: Mechanical properties and application in airframe load-bearing structure[J]. Acta Aeronautica et Astronautica Sinica, 2021,42(10):467-477. (张纪奎, 孔祥艺, 马少俊, 等. 激光增材制造高强高韧TC11钛合金力学性能及航空主承力结构应用分析[J]. 航空学报, 2021,42(10):467-477.Zhang Jikui, Kong Xiangyi, Ma Shaojun, et al. Laser additive manufactured high strength-toughness TC11 titanium alloy: Mechanical properties and application in airframe load-bearing structure[J]. Acta Aeronautica et Astronautica Sinica, 2021, 42(10): 467-477. [17] Ran Xianzhe, Cheng Hao, Wang Huaming, et al. Corrosion properties of laser melting-deposited corrosion-resistant ultrahigh strength steel AerMet100[J]. Transactions of Materials and Heat Treatment, 2012,33(12):126-131. (冉先喆, 程昊, 王华明, 等. 激光熔化沉积AerMet100耐蚀超高强度钢的耐蚀性[J]. 材料热处理学报, 2012,33(12):126-131.Ran Xianzhe, Cheng Hao, Wang Huaming, et al. Corrosion properties of laser melting-deposited corrosion-resistant ultrahigh strength steel AerMet100[J]. Transactions of Materials and Heat Treatment, 2012, 33(12): 126-131. [18] Ran Xianzhe, Liu Dong, Li Jia, et al. Effects of post homogeneity heat treatment processes on microstructure evolution behavior and tensile mechanical properties of laser additive manufactured ultrahigh-strength AerMet100 steel[J]. Materials Science & Engineering A, 2018,723:8-21. [19] Ran Xianzhe, Zhang Shuquan, Liu Dong, et al. Role of microstructural characteristics in combination of strength and fracture toughness of laser additively manufactured ultrahigh-strength AerMet100 steel[J]. Metallurgical and Materials Transactions A, 2021,52:1248-1259. doi: 10.1007/s11661-021-06148-1 [20] Cui Can, Wang Xiangming, Wu Bin, et al. Study on application of laser deposited additive manufacturing technology on aircraft undercarriage[J]. Aeronautical Manufacturing Technology, 2018,61(10):74-79. (崔灿, 王向明, 吴斌, 等. 激光直接沉积成形增材制造技术在飞机起落架上的应用研究[J]. 航空制造技术, 2018,61(10):74-79.Cui Can, Wang Xiangming, Wu Bin, et al. Study on application of laser deposited additive manufacturing technology on aircraft undercarriage[J]. Aeronautical Manufacturing Technology, 2018, 61(10): 74-79. -

下载:

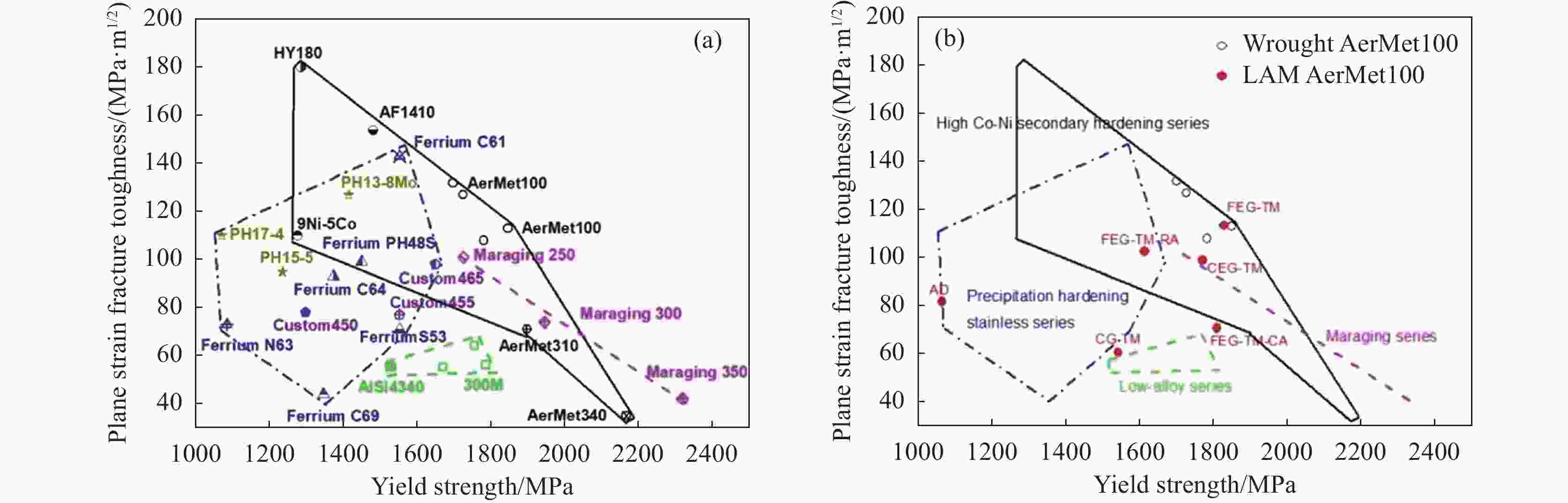

下载: