Microstructure and properties of inertia friction welding joint of TA18 titanium alloy tube

-

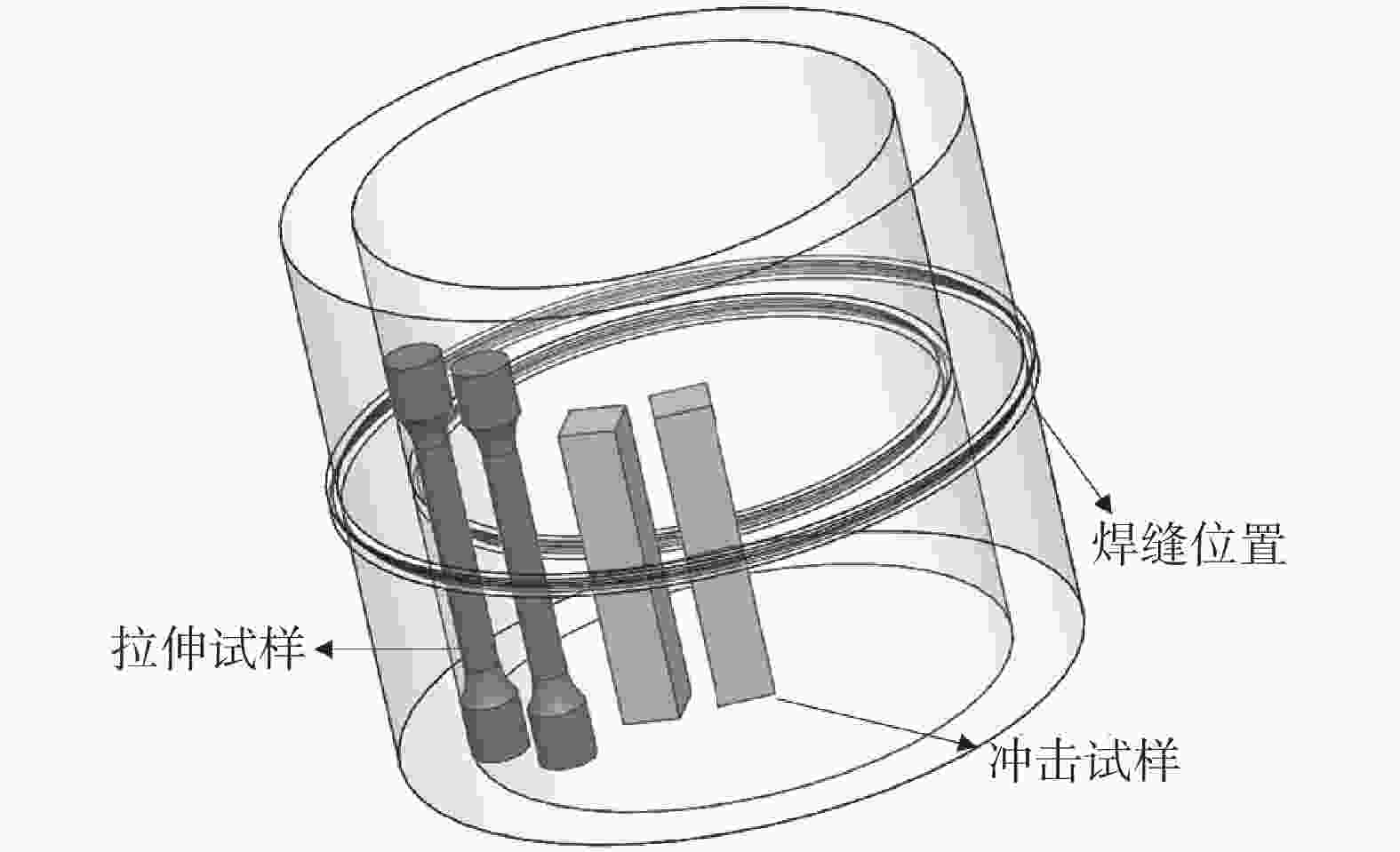

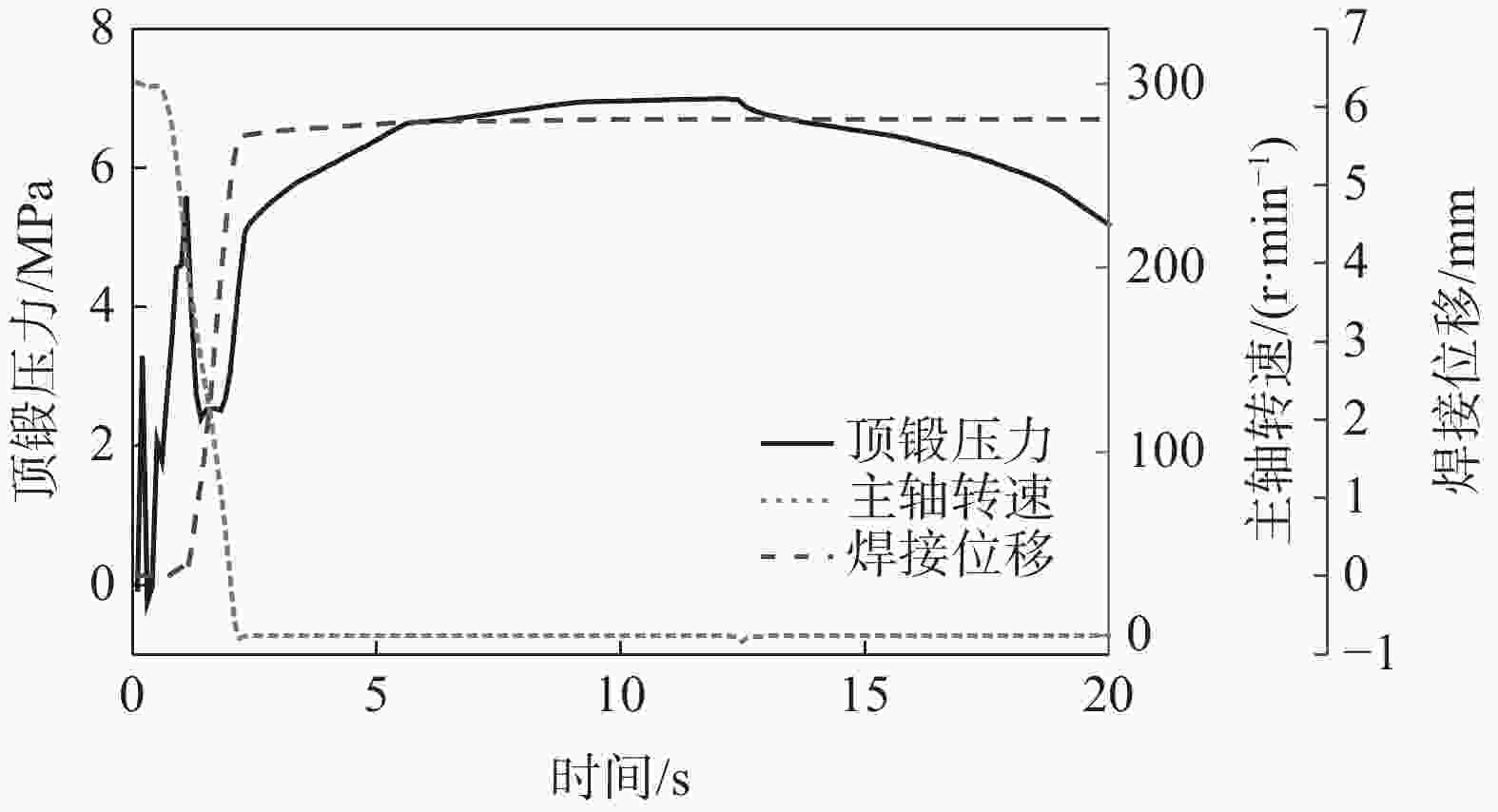

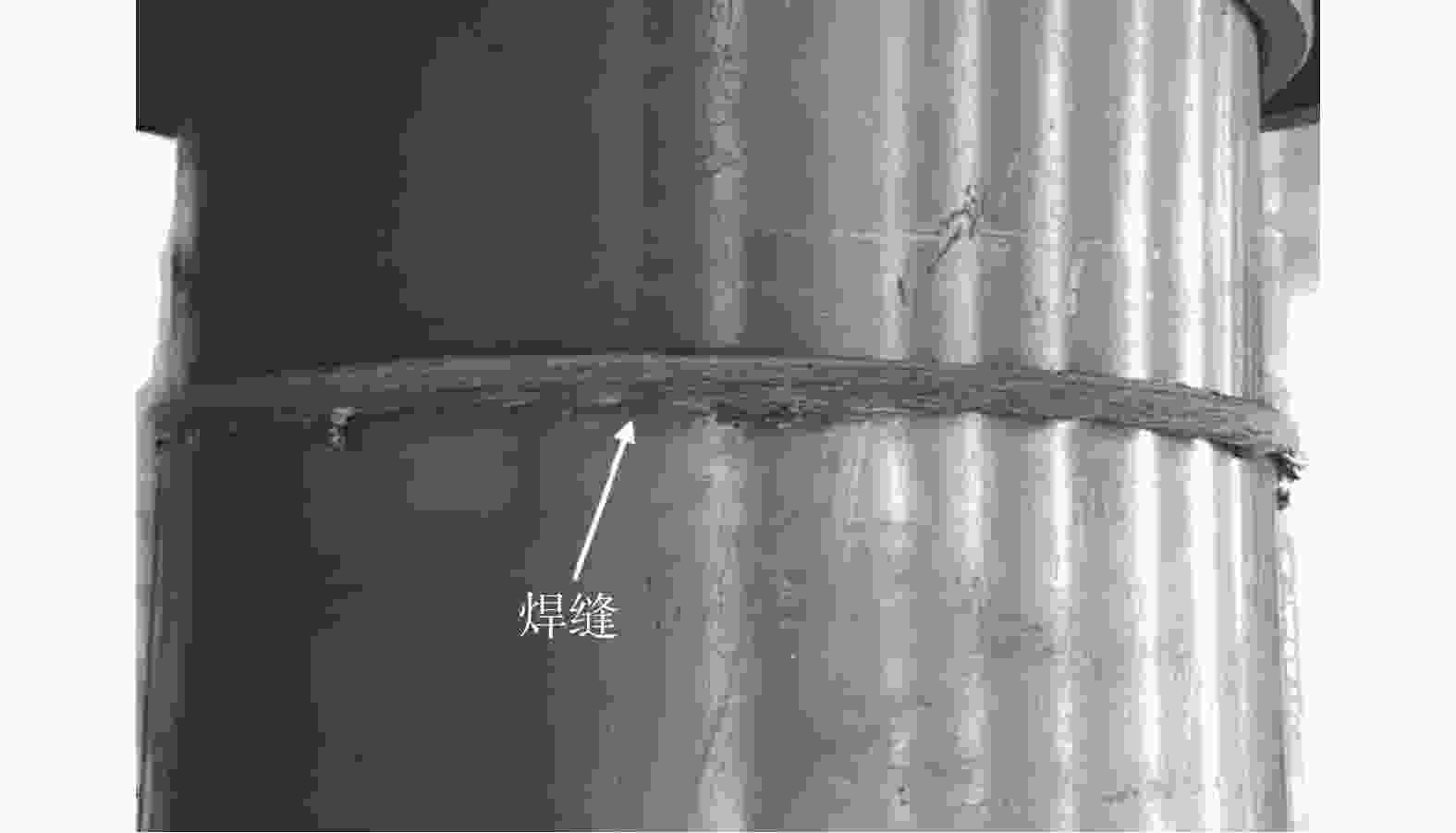

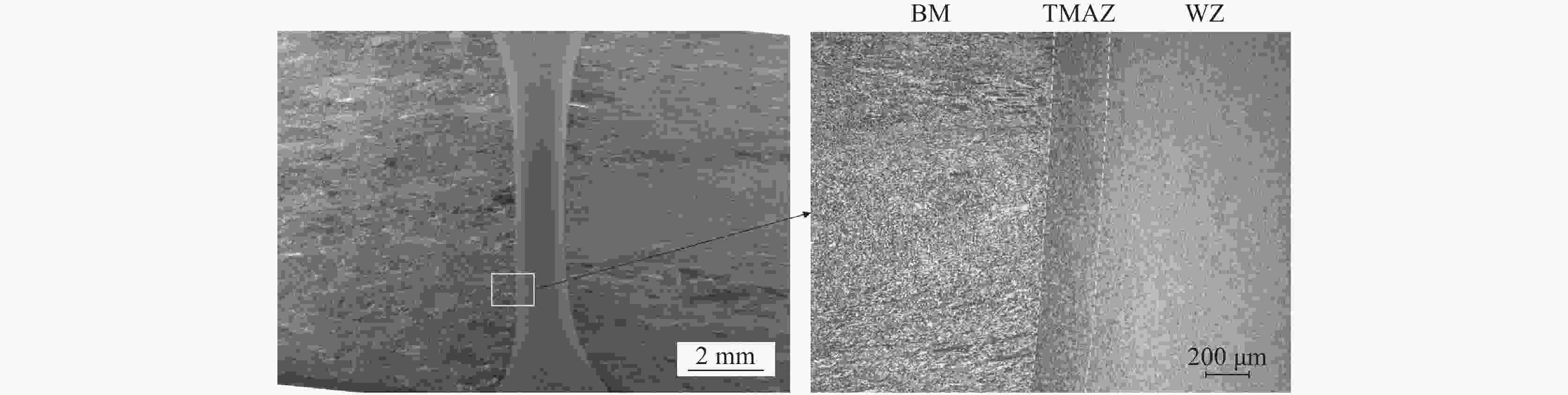

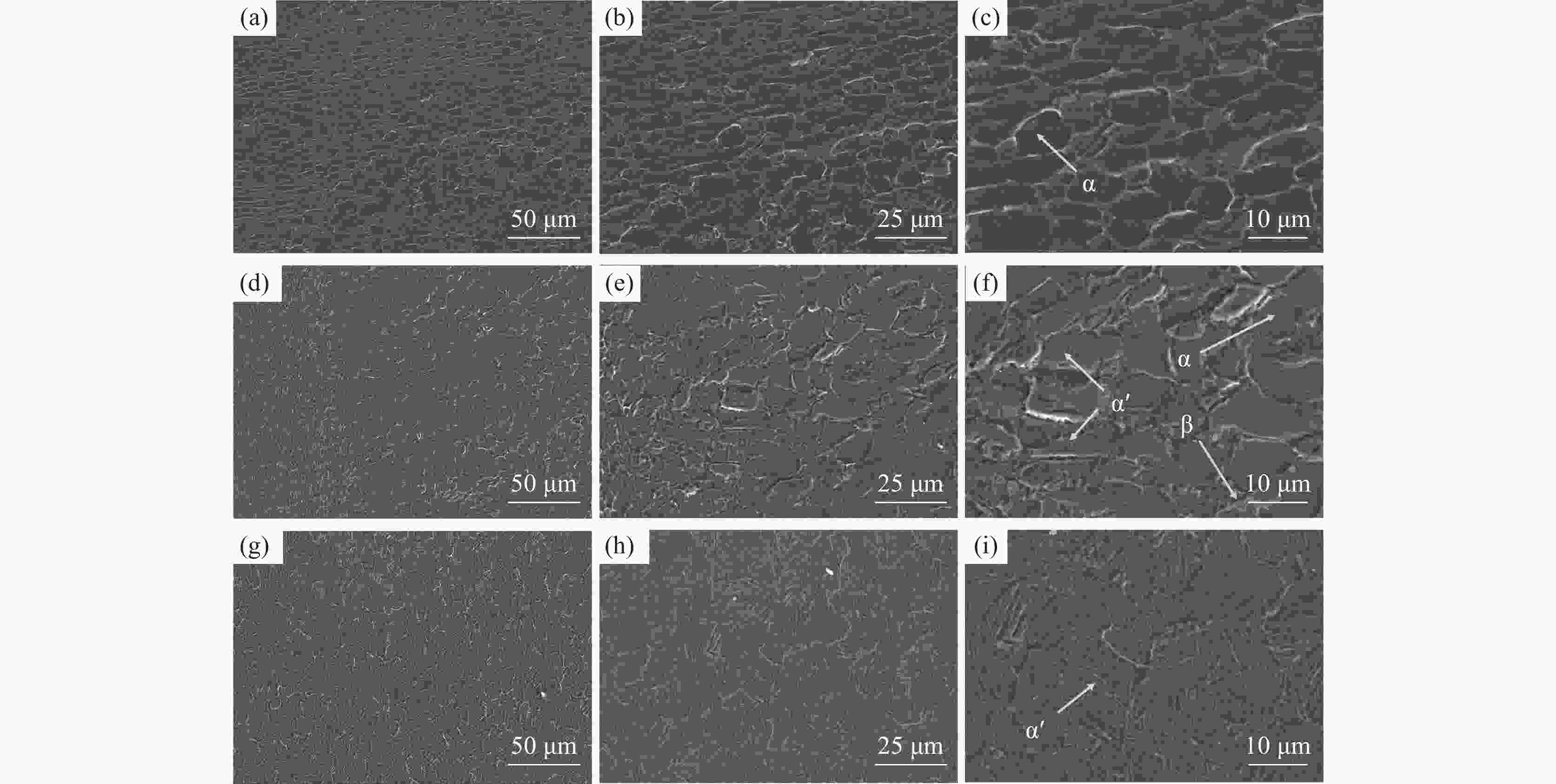

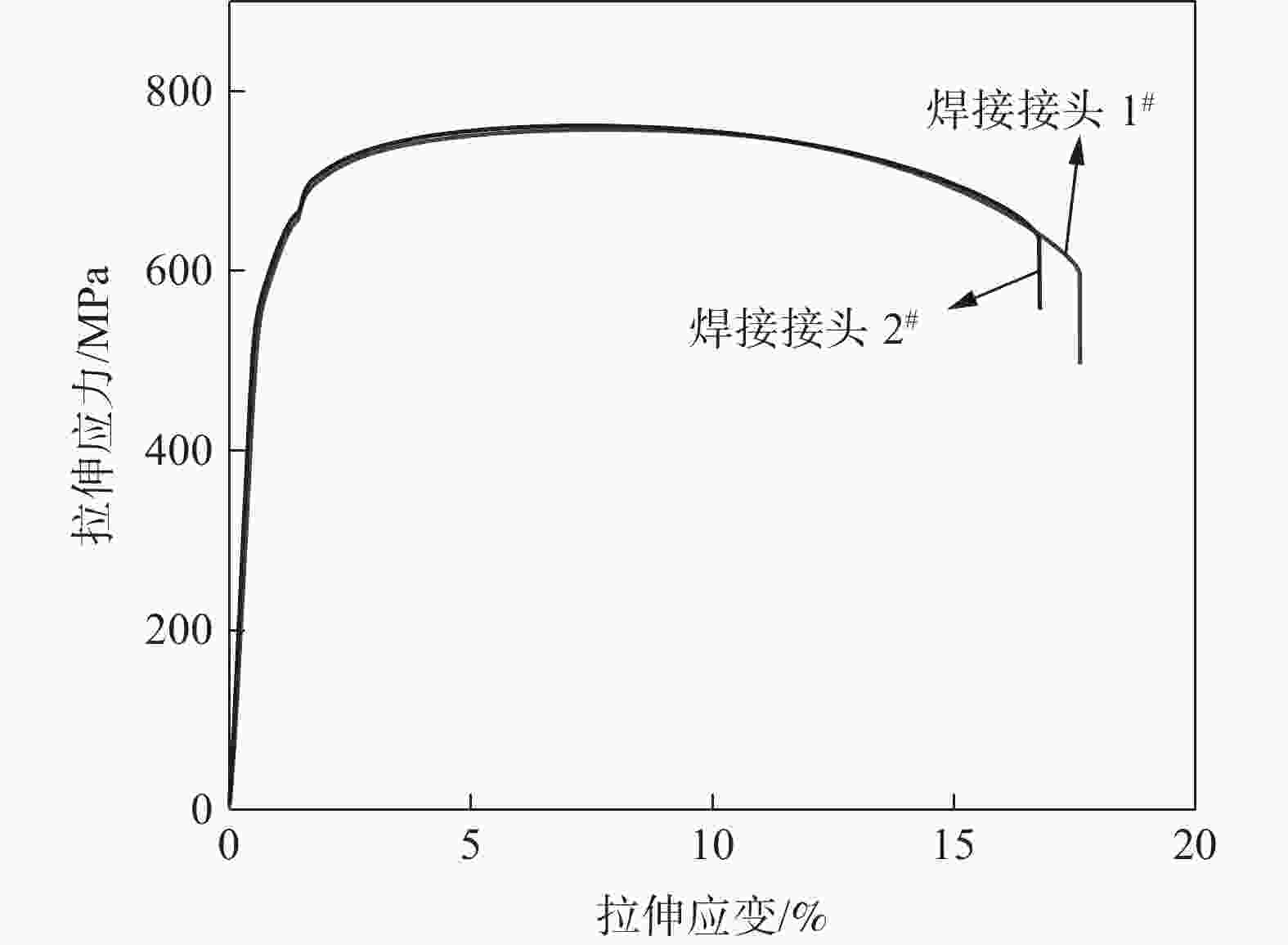

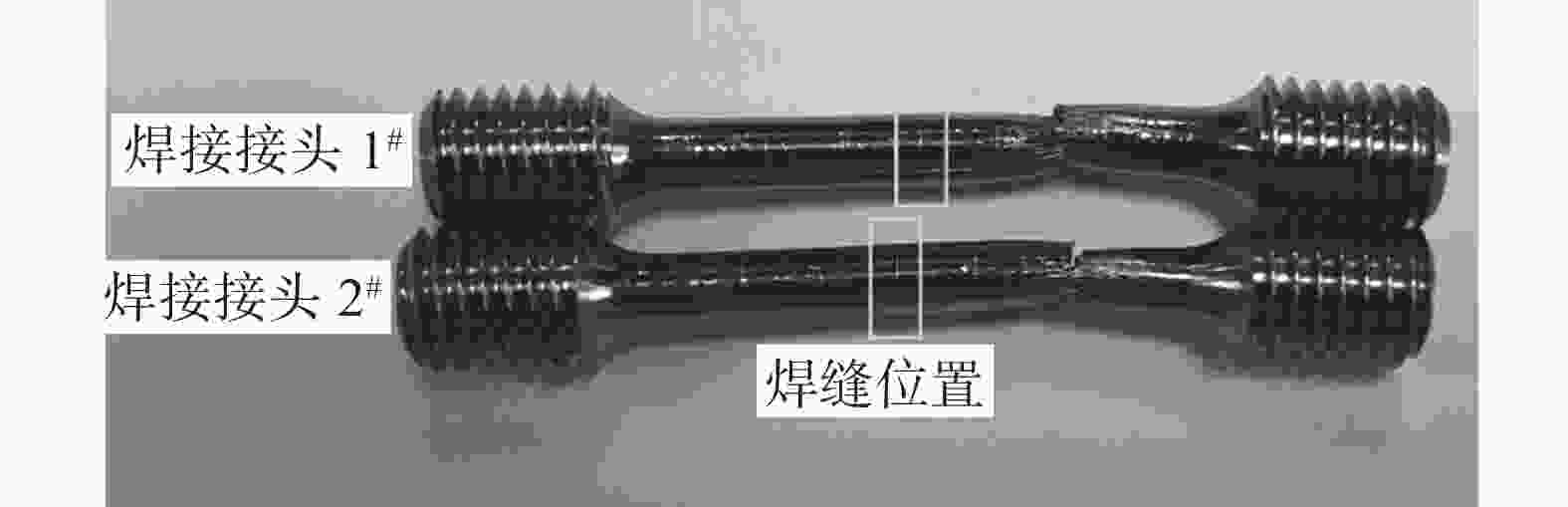

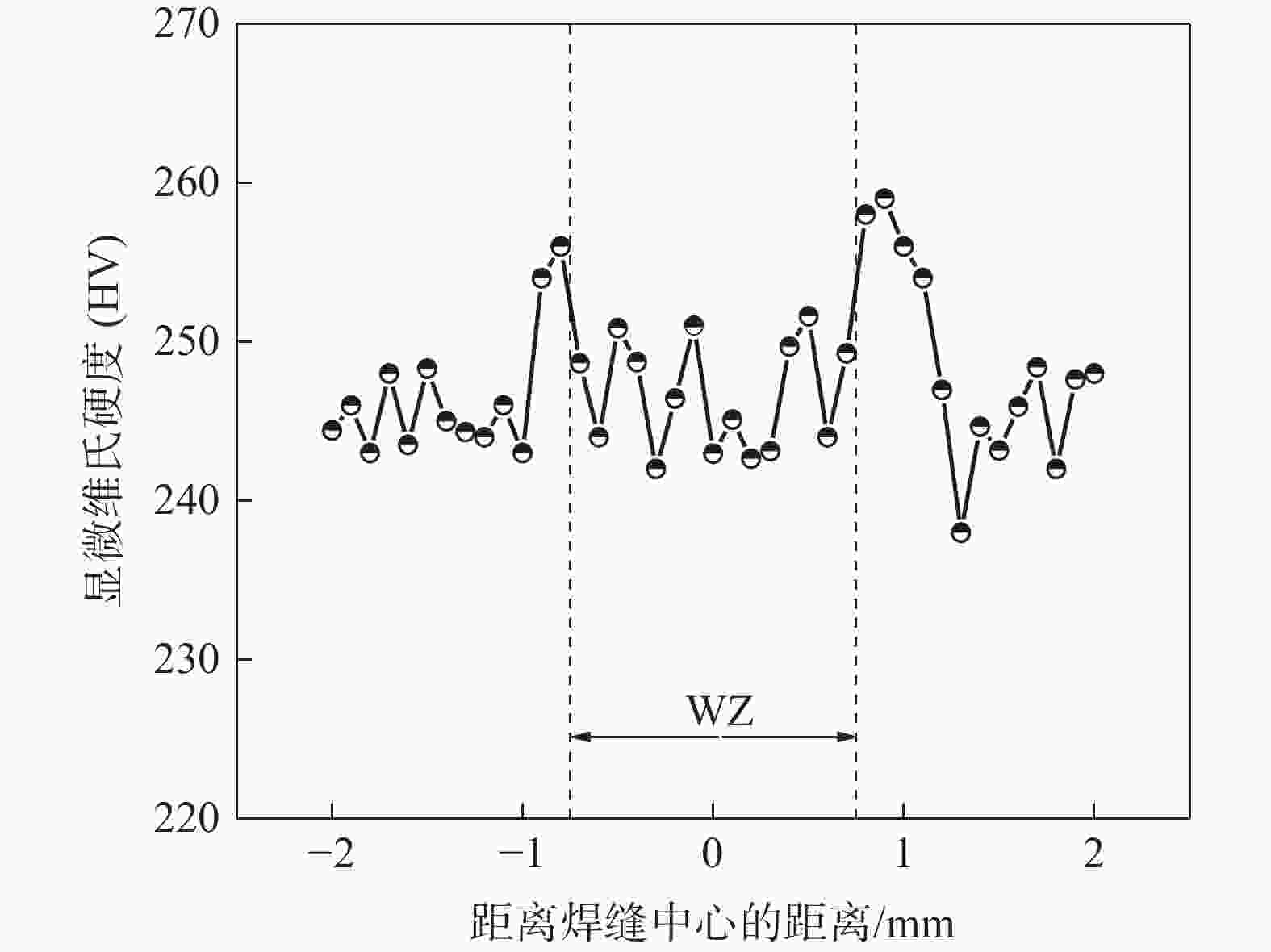

摘要: 对TA18钛合金管材开展惯性旋转摩擦焊接(IRFW)研究,采用光学显微镜与扫描电镜观察了TA18钛合金管摩擦焊接头各个区域的组织形态,结合焊接过程分析了组织的特征与演化机制,根据拉伸试验、室温冲击试验、显微硬度试验等测试结果分析了焊接接头的力学性能。结果表明,由于短时间内焊接接头处发生了强烈的塑性变形,IRFW接头焊缝处的组织为针状α′相;热影响区的组织为等轴α相、部分针状α′相和残余β相。TA18钛合金管材IRFW接头的抗拉强度与母材相当,且断裂位置均位于远离焊缝中心的位置。IRFW接头显微硬度较均匀,各区域硬度匹配性好,接头具有良好的冲击韧性,达到母材的96.85%。Abstract: Inertial rotary friction welding (IRFW) research was conducted on TA18 titanium alloy tube. The microstructure of the IRFW joint of TA18 titanium alloy tube was observed using optical microscopy and scanning electron microscopy, and the characteristics and evolution mechanism of the microstructure were analyzed in combination with the welding process. The mechanical properties of welded joints were analyzed using methods including tensile testing, impact testing, and microhardness testing. The results indicate that due to strong plastic deformation occurring at the welded joint in a short period of time, the microstructure of the welded zone of IRFW joint welded is mainly composed of needle-like α′ phase. The microstructure of the thermal mechanical affected zone of IRFW joint welded is mainly composed of equiaxed α phase, needle-like α′ phase and residual β phase. The tensile strength of the IRFW joint of TA18 titanium alloy tube is equivalent to that of the base material, and the fracture positions are all located far from the center of the weld zone. The microhardness of the IRFW joint is relatively uniform, and the hardness of each region can be matched. The impact toughness of the weld zone of the IRFW joint reached 96.85% of the base material.

-

表 1 TA18钛合金管化学成分

Table 1. Chemical composition of TA18 titanium alloy tube

% Al V Fe C O N H Ti 3.0 2.5 0.2 0.05 0.08 0.03 0.01 Balance 表 2 TA18管惯性摩擦焊接工艺参数

Table 2. Processing parameters for IRFW of TA18 tube

顶锻压力/MPa 转动惯量/(kg·m2) 主轴转速/(r·min-1) 保压时间/s 7 990 300 15 表 3 TA18管摩擦焊接头与母材的拉伸性能

Table 3. Tensile test result of BM and IRFW joint of TA18 tube

试样 抗拉强度/MPa 屈服强度/MPa 断后伸长率/% 断面收缩率/% 焊接接头1# 757 585 15.5 44 焊接接头2# 762 586 14.5 38 母材1# 747 635 13.5 41 母材2# 758 651 16.0 44 表 4 TA18管摩擦焊接头与母材的冲击韧性

Table 4. Impact toughness of BM and IRFW joint of TA18 tube

试样 冲击功/J 冲击韧性/(J·cm−2) 焊接接头1# 47.3 78.5 焊接接头2# 45.2 75 母材1# 45.8 76 母材2# 49.8 82.6 -

[1] Zhao Yongqing, Ge Peng, Xin Shewei. Progresses of R&D on Ti-alloy materials in recent 5 years[J]. Materials China, 2020,39(Z1):527-534, 557-558. (赵永庆, 葛鹏, 辛社伟. 近五年钛合金材料研发进展[J]. 中国材料进展, 2020,39(Z1):527-534, 557-558.Zhao Yongqing, Ge Peng, Xin Shewei. Progresses of R&D on Ti-alloy materials in recent 5 years[J]. Materials China, 2020, 39(Z1): 527-534, 557-558. [2] Zhao Heng, Li Lanyun, Xin Chao, et al. Application and research status of titanium alloy in oil and gas exploitation[J]. Hot Working Technology, 2023(4):1-4, 15. (赵恒, 李兰云, 辛超, 等. 钛合金在油气开采中的应用及研究现状[J]. 热加工工艺, 2023(4):1-4, 15.Zhao Heng, Li Lanyun, Xin Chao, et al. Application and research status of titanium alloy in oil and gas exploitation[J]. Hot Working Technology, 2023(4): 1-4, 15. [3] Zhang Xuesong, Chen Yongjun, Hu Junling. Recent advances in the development of aerospace materials[J]. Progress in Aerospace Sciences, 2018,97:22-34. doi: 10.1016/j.paerosci.2018.01.001 [4] Zheng Pengfei, Wang Wenbo, Zhang Xiaolong, et al. The effect of heat treatment system on the structure and properties of TA18 bar[J]. Forging & Metalforming, 2022(21):53-55. (郑鹏飞, 王文波, 张晓龙, 等. 热处理制度对TA18棒材组织与性能的影响[J]. 锻造与冲压, 2022(21):53-55.Zheng Pengfei, Wang Wenbo, Zhang Xiaolong, et al. The effect of heat treatment system on the structure and properties of TA18 bar[J]. Forging & Metalforming, 2022(21): 53-55. [5] Yang Jianchao, Xi Jinhui, Yang Yashe, et al. Research and application of TA18 titanium alloy tube in aerospace industry[J]. Titanium Industry Progress, 2014,31(4):6-10. (杨建朝, 席锦会, 杨亚社, 等. 航空航天用TA18钛合金管材的研发及应用[J]. 钛工业进展, 2014,31(4):6-10.Yang Jianchao, Xi Jinhui, Yang Yashe, et al. Research and application of TA18 titanium alloy tube in aerospace industry[J]. Titanium Industry Progress, 2014, 31(4): 6-10. [6] Huang Tao, Yang Fangfang, Zhan Mei, et al. Section flattening in numerical control bending process of TA18 high strength tube[J]. Rare Metal Materials and Engineering, 2018,47(8):2347-2352. doi: 10.1016/S1875-5372(18)30190-5 [7] Luo Dengchao, Nan Li, Yang Yashe, et al. Effect of annealing temperature on mechanical properties and microstructure of TA18 tubes[J]. Hot Working Technology, 2012,41(20):206-208. (罗登超, 南莉, 杨亚社, 等. 退火温度对TA18管材性能和组织的影响[J]. 热加工工艺, 2012,41(20):206-208.Luo Dengchao, Nan Li, Yang Yashe, et al. Effect of annealing temperature on mechanical properties and microstructure of TA18 tubes[J]. Hot Working Technology, 2012, 41(20): 206-208. [8] Li Junzhao, Yu Hang, Fan Cheng, et al. Comparative study on welding process of TA18 titanium alloy sheet[J]. Titanium Industry Progress, 2023,40(2):30-34. (李军兆, 于航, 樊程, 等. TA18钛合金板材焊接工艺对比研究[J]. 钛工业进展, 2023,40(2):30-34.Li Junzhao, Yu Hang, Fan Cheng, et al. Comparative study on welding process of TA18 titanium alloy sheet[J]. Titanium Industry Progress, 2023, 40(2): 30-34. [9] Guo Jilong, Fu Juan, Zhao Yong, et al. Study on microstructure and corrosion resistance of TA18 titanium alloy TIG welding joint[J]. Hot Working Technology, 2024(7):11-15. (郭纪龙, 付娟, 赵勇, 等. TA18钛合金TIG焊接头组织及耐腐蚀性能研究[J]. 热加工工艺, 2024(7):11-15.Guo Jilong, Fu Juan, Zhao Yong, et al. Study on microstructure and corrosion resistance of TA18 titanium alloy TIG welding joint[J]. Hot Working Technology, 2024(7): 11-15. [10] Chen Wei, Zhang Yupeng, Dong Yong, et al. Effect of laser welding parameters on microstructure and mechanical properties of titanium alloy sheet[J]. Journal of Netshape Forming Engineering, 2022,14(5):100-108. (陈伟, 张宇鹏, 董勇, 等. 激光焊接参数对钛合金薄板组织及力学性能影响[J]. 精密成形工程, 2022,14(5):100-108.Chen Wei, Zhang Yupeng, Dong Yong, et al. Effect of laser welding parameters on microstructure and mechanical properties of titanium alloy sheet[J]. Journal of Netshape Forming Engineering, 2022, 14(5): 100-108. [11] Long Jian, Zhang Linjie, Zhang Long, et al. Effect of post-welding heat treatment on microstructure and properties of electron beam welding joint of new high-strength TB18 titanium alloy[J]. Welding in the World, 2024,68(1):155-162. doi: 10.1007/s40194-023-01644-x [12] Zhang Chunbo, Wu Yanquan, Piao Dongguang, et al. Inertia friction welding procedure of TA19 titanium alloy[J]. Transactions of the China Welding Institution, 2018,39(12):44-48, 131. (张春波, 乌彦全, 朴东光, 等. TA19钛合金惯性摩擦焊接工艺[J]. 焊接学报, 2018,39(12):44-48, 131.Zhang Chunbo, Wu Yanquan, Piao Dongguang, et al. Inertia friction welding procedure of TA19 titanium alloy[J]. Transactions of the China Welding Institution, 2018, 39(12): 44-48, 131. [13] Zhao Zhanglong, Song Xuyang, Cao Lanchuan, et al. Effect of isothermal deforming on the microstructure and property of inertial friction welding IMI834/Ti6246 dual titanium alloy[J]. Rare Metal Materials and Engineering, 2020,49(7):2388-2392. (赵张龙, 宋旭阳, 曹澜川, 等. 等温变形对惯性摩擦焊IMI834/Ti6246双钛合金组织与性能的影响[J]. 稀有金属材料与工程, 2020,49(7):2388-2392.Zhao Zhanglong, Song Xuyang, Cao Lanchuan, et al. Effect of isothermal deforming on the microstructure and property of inertial friction welding IMI834/Ti6246 dual titanium alloy[J]. Rare Metal Materials and Engineering, 2020, 49(7): 2388-2392. [14] Liu Yingying, Tian Wantao, Yang Qihao, et al. Inertia radial friction welding of Ti60(near-α)/TC18(near-β) bimetallic components: Interfacial bonding mechanism, heterogenous microstructure and mechanical properties[J]. Materials Characterization, 2024,208:113598. doi: 10.1016/j.matchar.2023.113598 [15] Ho Thi My Nu, Truyen The Le, Luu Phuong Minh, et al. A study on rotary friction welding of titanium alloy (Ti6Al4V)[J]. Advances in Materials Science and Engineering, 2019,2019(1):1-9. [16] Zhou Feng, Cao Yuxin, Wan Xiangliang. Effect of rare earth lanthanum addition on toughness of coarse-grained heat-affect zone of high strength low alloy steel[J]. Transactions of Materials and Heat Treatment, 2021, 42(12):84-92. (周峰, 曹羽鑫, 万响亮. 稀土镧的添加对低合金高强钢粗晶热影响区韧性的影响[J]. 材料热处理学报, 2021, 42(12):84-92.Zhou Feng, Cao Yuxin, Wan Xiangliang. Effect of rare earth lanthanum addition on toughness of coarse-grained heat-affect zone of high strength low alloy steel[J]. Transactions of Materials and Heat Treatment, 2021, 42(12): 84-92. [17] Wang Shiqing, Ma Tiejun, Li Wenya, et al. Microstructure and fatigue properties of linear friction welded TC4 titanium alloy joints[J]. Science and Technology of Welding and Joining, 2017,22(3):177-181. doi: 10.1080/13621718.2016.1212971 [18] Gavalec M, Barenyi I, Krbata M, et al. The effect of rotary friction welding conditions on the microstructure and mechanical properties of Ti6Al4V titanium alloy welds[J]. Materials, 2023,16(19):6492. doi: 10.3390/ma16196492 -

下载:

下载: