Effect of V content on microstructure and properties of laser cladding Fe-Cr alloy coatings

-

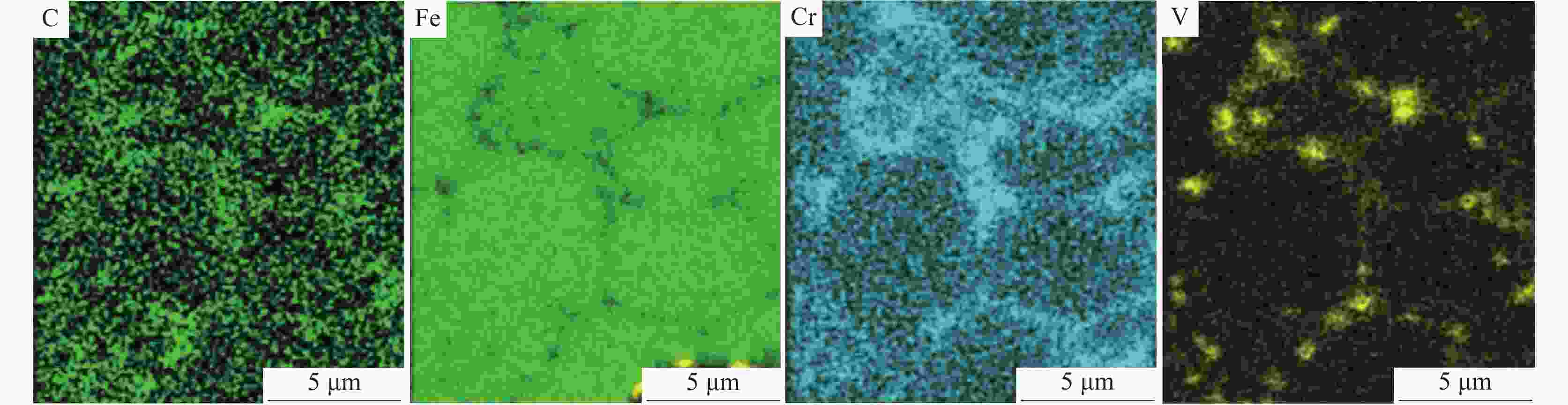

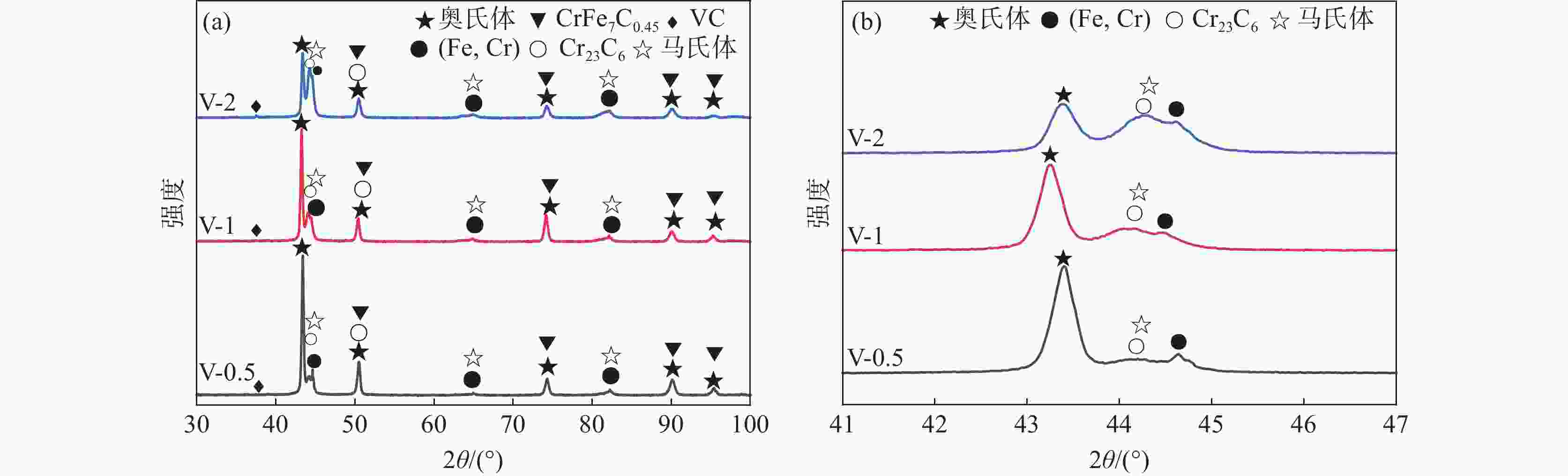

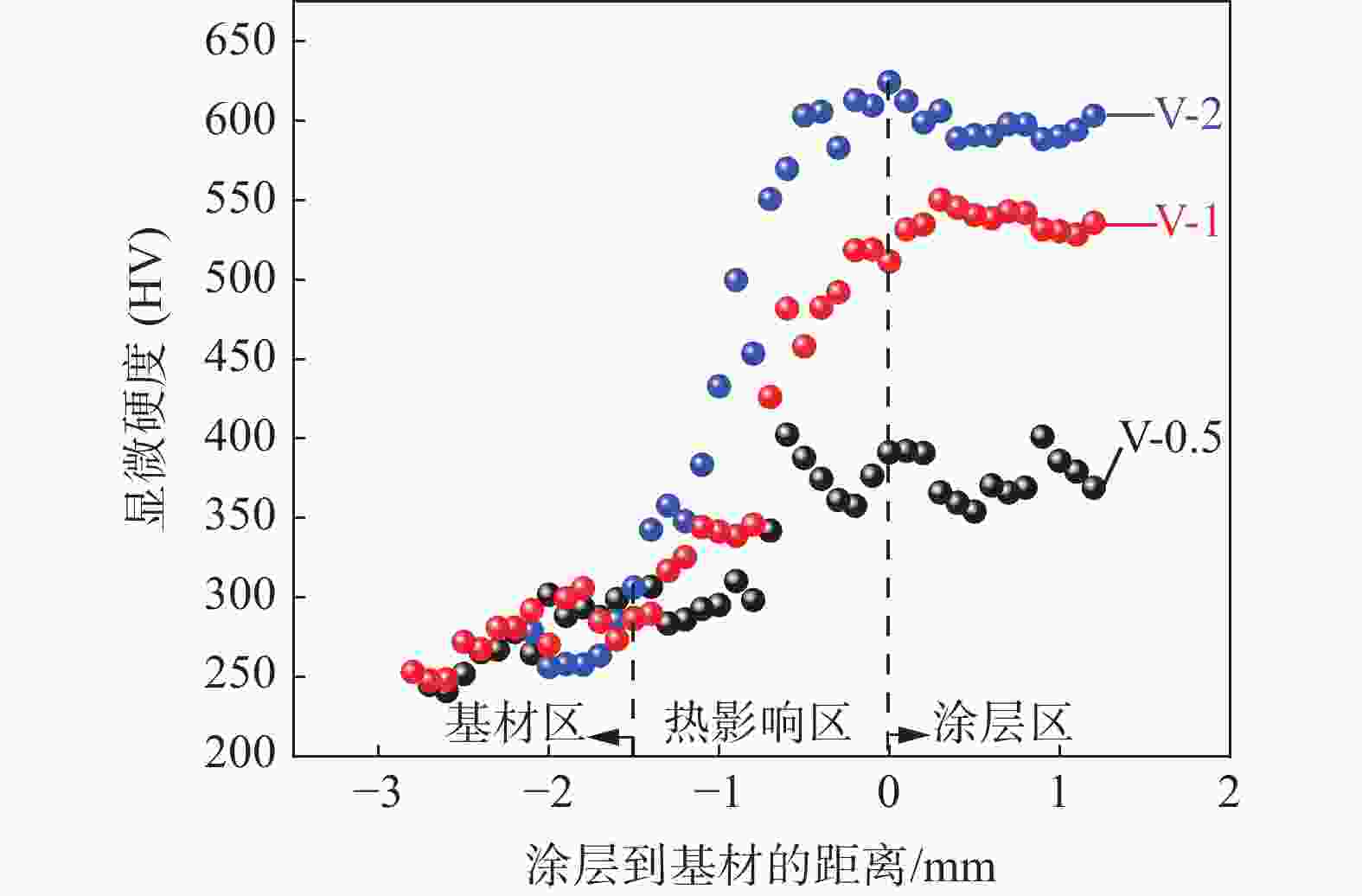

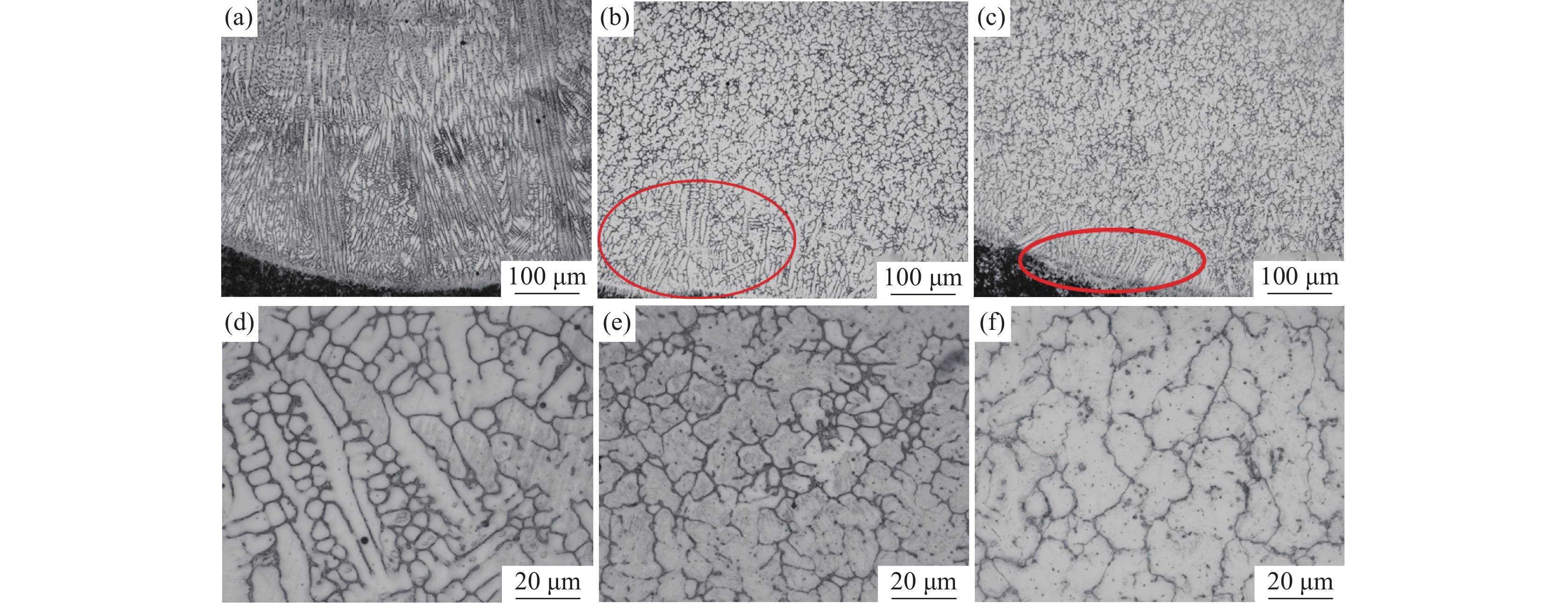

摘要: 采用激光熔覆技术制备了不同V含量的铁铬合金涂层,结合金相观察、SEM & EDS、X-射线衍射等分析方法研究了V含量变化时激光熔覆铁铬合金涂层的显微组织与性能的变化规律。结果表明,V含量较低时铁铬合金涂层以树枝晶生长模式为主,涂层界面的树枝晶生长过程中Cr元素来不及完全固溶到基体中,引起基体衍射峰向高角度处偏移。增加V含量能够促进树枝晶向胞状晶转变,有效改善了Cr元素在基体中不能完全固溶的现象。VC的形成促进了凝固过程中γ-Fe向马氏体的转变,涂层硬度提升,但当V含量增加到2%时,原料中高熔点钒铁含量增加,导致涂层中气孔缺陷增加,引起涂层耐磨性能降低。当V含量为1%时涂层性能最佳。Abstract: Iron-chromium alloy coatings with varying V content were fabricated using laser cladding. The microstructural and performance variations of the laser-cladded iron-chromium alloy coatings with different V contents were investigated using metallographic observation, SEM & EDS, and X-ray diffraction analysis. The results indicate that at lower V content, the iron-chromium alloy coating predominantly exhibits a dendritic growth mode. At the coating interface, the dendritic grew rapidly, Cr elements do not have sufficient time to completely dissolve into the matrix, causing the matrix diffraction peaks to shift to higher angles. Increasing V content promotes the transition from dendritic to cellular growth, effectively improving the incomplete dissolution of Cr elements in the matrix and leading to a more uniform coating structure. The formation of VC promotes the transformation of γ-Fe to martensite during solidification, and the hardness of the coating increases. However, when the V content increases to 2%, the ferrovanadium content with a higher melting point increases, resulting in an increase in pore defects, which makes the wear resistance of the coating decrease. When the V content in the coating is 1 %, the hardness and wear resistance are the best.

-

Key words:

- laser cladding /

- VC /

- iron-chromium alloy coating /

- microstructure /

- performance

-

表 1 60CrMnMo基材成分

Table 1. Elemental composition of 60CrMnMo basic materials

% Ni C Si Mn Cr Mo Fe 0.3 0.56 0.25 0.75 1.12 0.25 余量 表 2 各种混合粉末的元素组成

Table 2. Elemental compositions of various mixed powders

% 试验样品 Fe V Si Cr C V-0.5 87.80 0.50 1.00 9.70 1.00 V-1 87.30 1.00 1.00 9.70 1.00 V-2 86.30 2.00 1.00 9.70 1.00 -

[1] Nie Huiwen, Zeng Songsheng, Nie Junhong, et al. Influence of VC addition amount on microstructure and properties of laser clad Fe50Mn30Cr10Co10 high-entropy alloy coating[J]. Journal of Mechanical Engineering Materials, 2023,47(4):7-11, 27. (聂辉文, 曾松盛, 聂俊红, 等. VC添加量对激光熔覆Fe50Mn30Cr10Co10高熵合金涂层组织和性能的影响[J]. 机械工程材料, 2023,47(4):7-11, 27. doi: 10.11973/jxgccl202304002Nie Huiwen, Zeng Songsheng, Nie Junhong, et al. Influence of VC addition amount on microstructure and properties of laser clad Fe50Mn30Cr10Co10 high-entropy alloy coating[J]. Journal of Mechanical Engineering Materials, 2023, 47(4): 7-11, 27. doi: 10.11973/jxgccl202304002 [2] Wang Haomin, Wang Guoqing, Xiong Yangkai, et al. Microstructure and mechanical properties of laser cladded VC-Cr7C3 composite cladding layer[J]. Heat Treatment of Metals, 2022,47(11):245-252. (王皓民, 汪国庆, 熊杨凯, 等. 激光熔覆VC-Cr7C3复合熔覆层的组织与力学性能[J]. 金属热处理, 2022,47(11):245-252.Wang Haomin, Wang Guoqing, Xiong Yangkai, et al. Microstructure and mechanical properties of laser cladded VC-Cr7C3 composite cladding layer[J]. Heat Treatment of Metals, 2022, 47(11): 245-252. [3] Zhang Wei, Feng Qiuhong, Wang Eryi, et al. Microstructure and hardness of laser cladded in-situ synthesized VC reinforced Fe-Ni based composite coating[J]. Heat Treatment of Metals, 2019,44(7):190-193. (张伟, 冯秋红, 王尔亦, 等. 激光熔覆原位生成VC增强Fe-Ni基复合涂层的组织与硬度[J]. 金属热处理, 2019,44(7):190-193.Zhang Wei, Feng Qiuhong, Wang Eryi, et al. Microstructure and hardness of laser cladded in-situ synthesized VC reinforced Fe-Ni based composite coating[J]. Heat Treatment of Metals, 2019, 44(7): 190-193. [4] Lü Yufang, Xu Peng, Liang Rou, et al. Corrosion resistance of VC-reinforced Fe-based SMA coatings by laser cladding[J]. Surface Coatings Technology, 2024,478(2024):130457. [5] Rahman U N, Capuano L, Cabeza S, et al. Directed energy deposition and characterization of high-carbon high speed steels[J]. Additive Manufacturing, 2019, 30(2019): 1-12. [6] Cheng Heng, Liu Shuai, Jiang Shaoteng, et al. Effect of CeO2 on the Microstructure and properties of in situ nano-VC reinforced sub-micron Fe-based laser cladding layers[J]. Journal of Materials Engineering and Performance, 2024,33:1-11. [7] Shi Kao, Zhou Wenqian, Sun Yufu, et al. Effect of vanadium carbide reinforced particles on wear resistance of laser cladding Fe-Co duplex coating[J]. Journal of Thermal Spray Technology, 2023,32(1):124-134. doi: 10.1007/s11666-022-01477-y [8] Zhang Hui, Wu Dongting, Luan Tao, et al. Effects of graphite particle size on microstructure and properties of in-situ Ti-V carbides reinforced Fe-based laser cladding layers[J]. International Journal of Electrochemical Science, 2019, 14(3): 2208-2215. [9] Zhuo Yan, Li Chengxiang, Shi Xin, et al. Evaluation model of electromagnetic pulse welding effect based on Vc-β trajectory curve[J]. Journal of Materials Research and Technology, 2022,20:616-626. [10] Li Xuejun, Liu Ying, Zhou Tingchuan. Improvement in microstructure and wear-resistance of high chromium cast iron/medium carbon steel bimetal with high vanadium[J]. Materials Research Express, 2021, 8(4): 1-9. [11] Ren Yiqun, Li Liqun, Zhou Yuandong, et al. In situ synthesized VC reinforced Fe-based coating by using extreme high-speed laser cladding[J]. Materials Letters, 2022, 315: 131962. [12] Peng Zhiliang, Zhang Jian, Zhang Mingjun, et al. Laser in-situ preparation and mechanical properties of VC reinforced Fe-based wear-resistant composite cladding[J]. Ceramics International, 2022, 48(19): 28240-28249. [13] Gao Yu, Liu Ying, Wang Lu, et al. Microstructure evolution and wear resistance of laser cladded 316L stainless steel reinforced with in-situ VC-Cr7C3[J]. Surface Coatings Technology, 2022, 435: 128264. [14] Kirchgaßner M, Badisch E, Franek F. Behaviour of iron-based hardfacing alloys under abrasion and impact[J]. Wear, 2008,265(5):772-779. [15] Liang Z G, Zhan J M, Shi W Q, et al. Parameters optimization of the laser cladding of a Fe-based VC composite coating using response surface methodology (RSM)[J]. Lasers in Engineering, 2021,49:179-203. [16] Liu Changyu, Xu Peng, Pang Chi, et al. Phase transformation in Fe–Mn–Si SMA/WC composite coating developed by laser cladding[J]. Materials Chemistry and Physics, 2021,267:124595. [17] Chung R J, Tang X, Li D Y, et al. Microstructure refinement of hypereutectic high Cr cast irons using hard carbide-forming elements for improved wear resistance[J]. Wear, 2013, 301(1-2): 695-706. [18] Eremin E N, Losev A, Ponomarev I A, et al. Structure and properties of the weld metal N8G6M3FTB after aging[J]. AIP Conference Proceedings, 2019, 214: 40004. [19] Yang Xiong, Chen Yarong, Zhang Zhenlin, et al. Study on microstructure and properties of laser-clad Fe-based (Ti, V)C composite coatings[J]. Surface Coatings Technology, 2023,464:129552. [20] Kannan Rajesh G, Sathiya P, Bharathi D T K, et al. Welding parameter optimization by whale optimization algorithm and experimental investigation on microstructure and mechanical properties of spin arc welded 15CDV6 HSLA steel[J]. Metals and Materials International, 2023,29(9):2743-2759. doi: 10.1007/s12540-023-01406-w [21] Wang Haiyang, Zhang Song, Zhang Chunhua, et al. Effects of V and Cr on laser cladded Fe-based coatings[J]. Coatings, 2018,8(3):107-118. doi: 10.3390/coatings8030107 [22] Cao Yabin, Ma Zeming, Zhu Hao, et al. Evolution behavior regulation of carbide in Fe-based laser cladding coating[J]. Materials Research Express, 2019,6(11):116590-116590. doi: 10.1088/2053-1591/ab4c5f [23] Zong Weian, Zhang Song, Zhang Chunhua, et al. Preparation and characterization of in situ carbide particle reinforced Fe-based gradient materials by laser melt deposition[J]. Coatings, 2019,9(8):467-481. doi: 10.3390/coatings9080467 [24] Wang Yanfang, Zhou Xuejing, Song Zihan, et al. Microstructure and tribocorrosion properties of Cr-W-Mo-V coating fabricated via laser hot-wire cladding[J]. China Surface Engineering 2024, 37(3): 1-12. (王彦芳, 周雪景, 宋子翰, 等. 热丝激光熔覆Cr-W-Mo-V钢涂层组织与腐蚀磨损性能[J]. 中国表面工程, 2024, 37(3): 1-12.Wang Yanfang, Zhou Xuejing, Song Zihan, et al. Microstructure and tribocorrosion properties of Cr-W-Mo-V coating fabricated via laser hot-wire cladding[J]. China Surface Engineering 2024, 37(3): 1-12. -

下载:

下载: