Research on the characteristics of cold-rolled deformation zone of thin strip and the applicability of contact pressure model

-

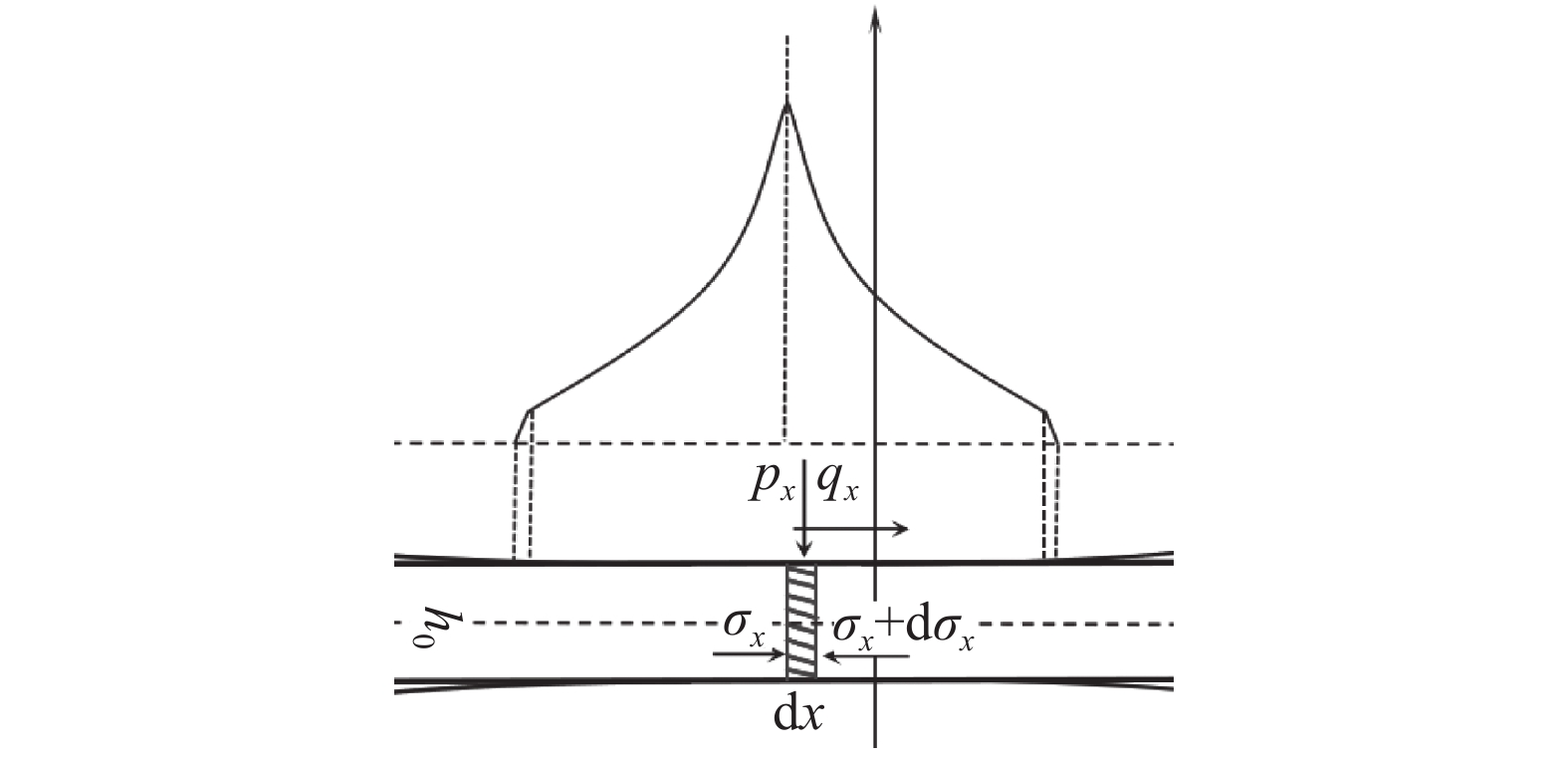

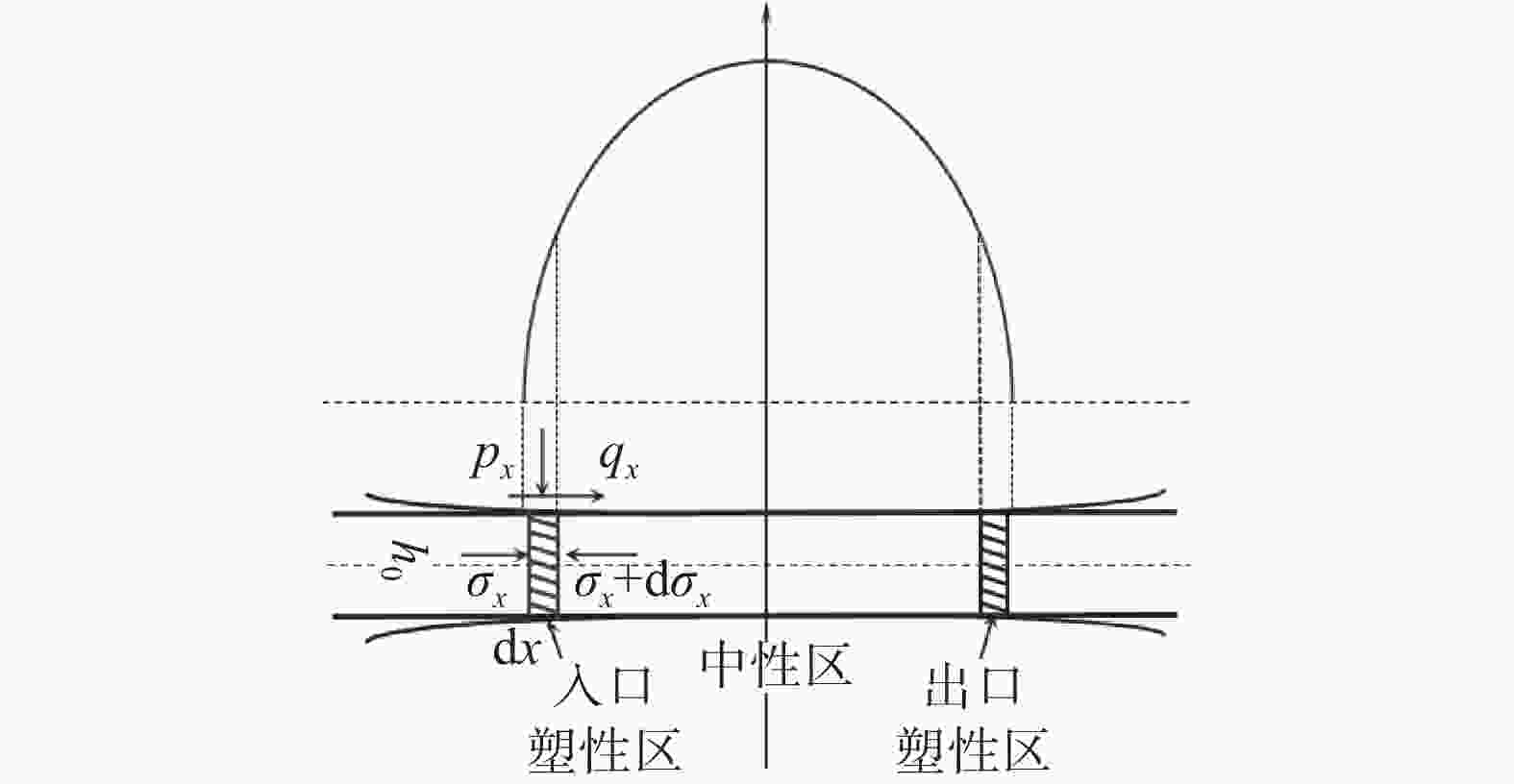

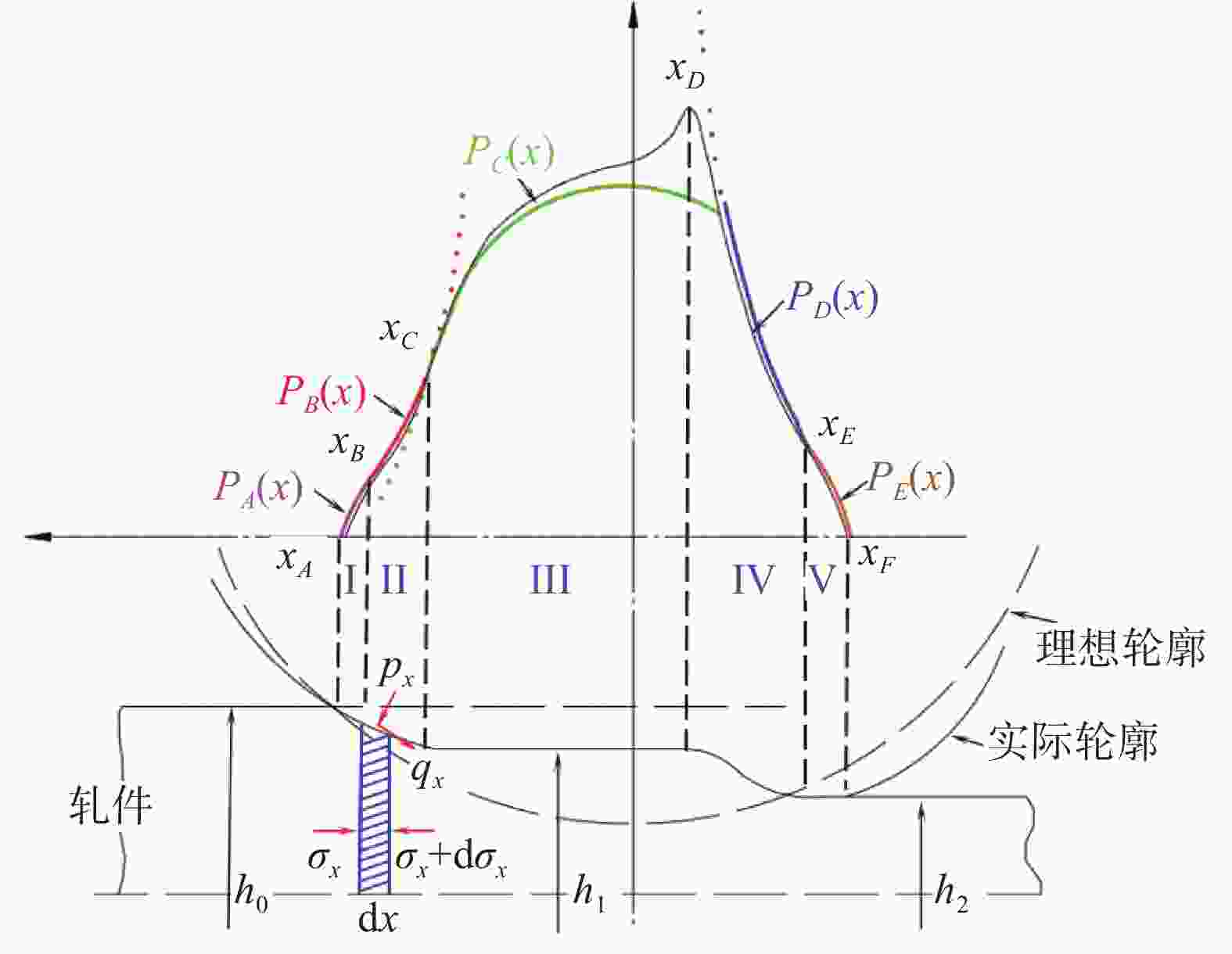

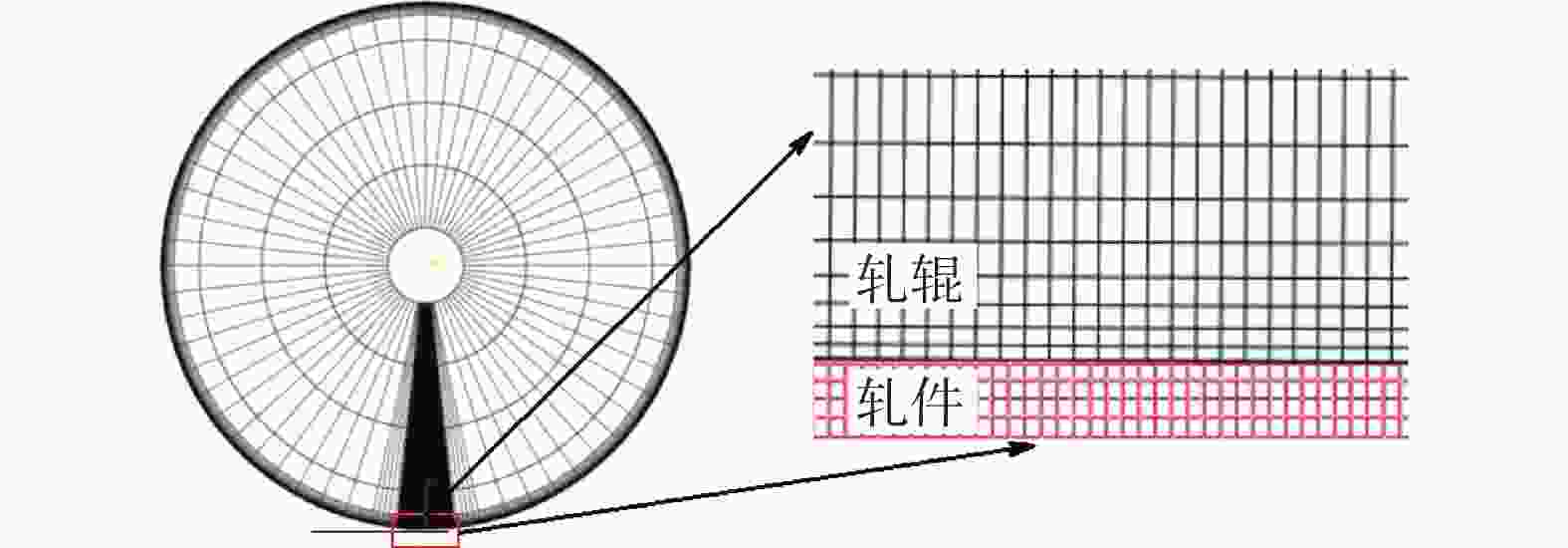

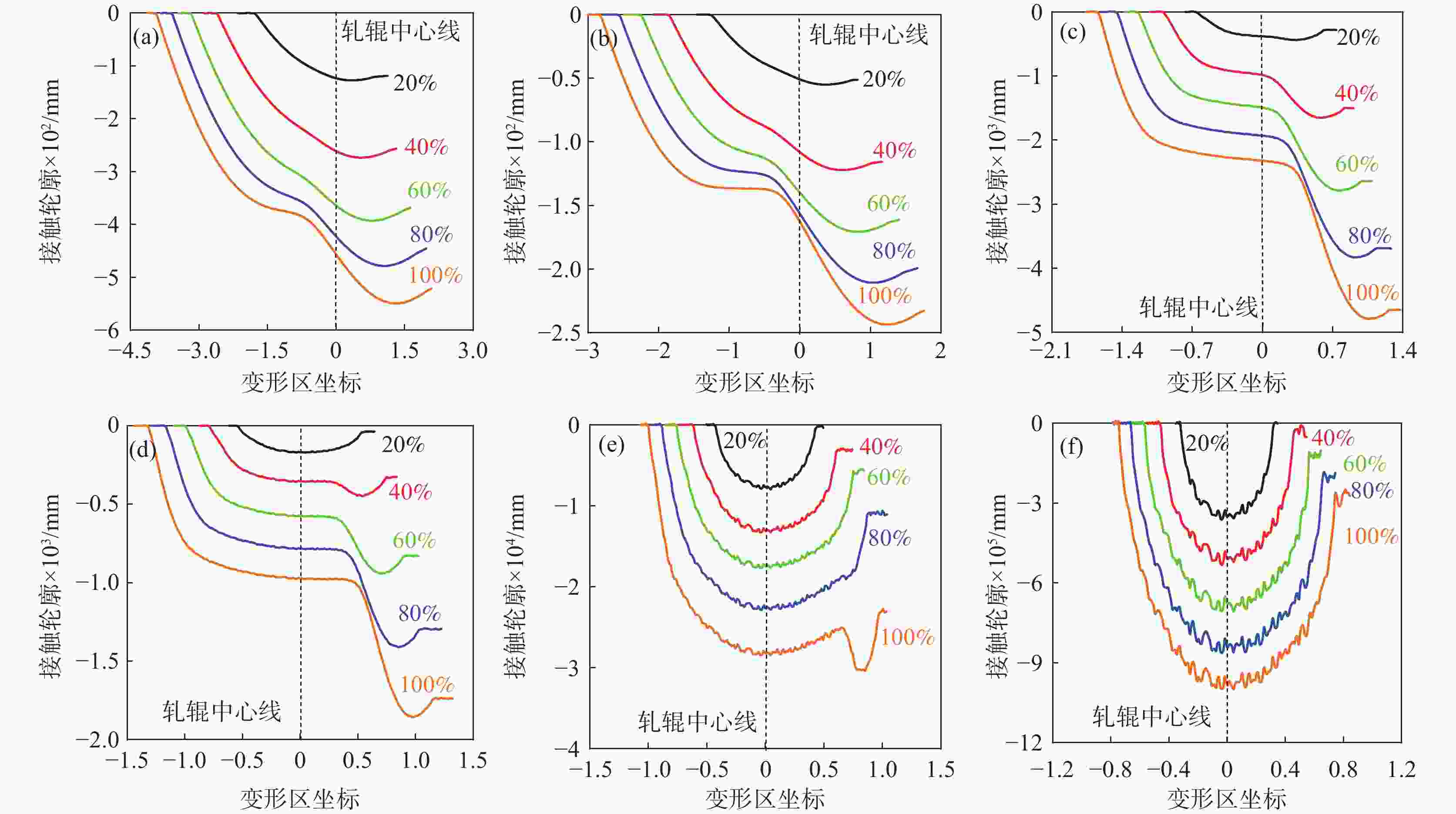

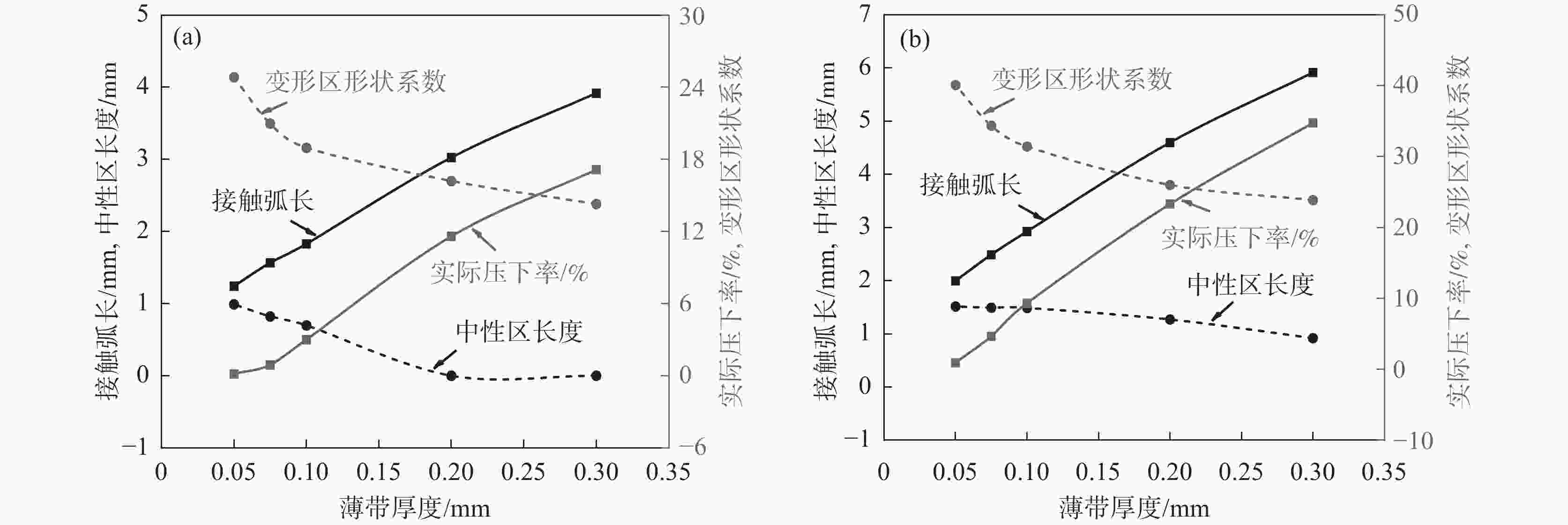

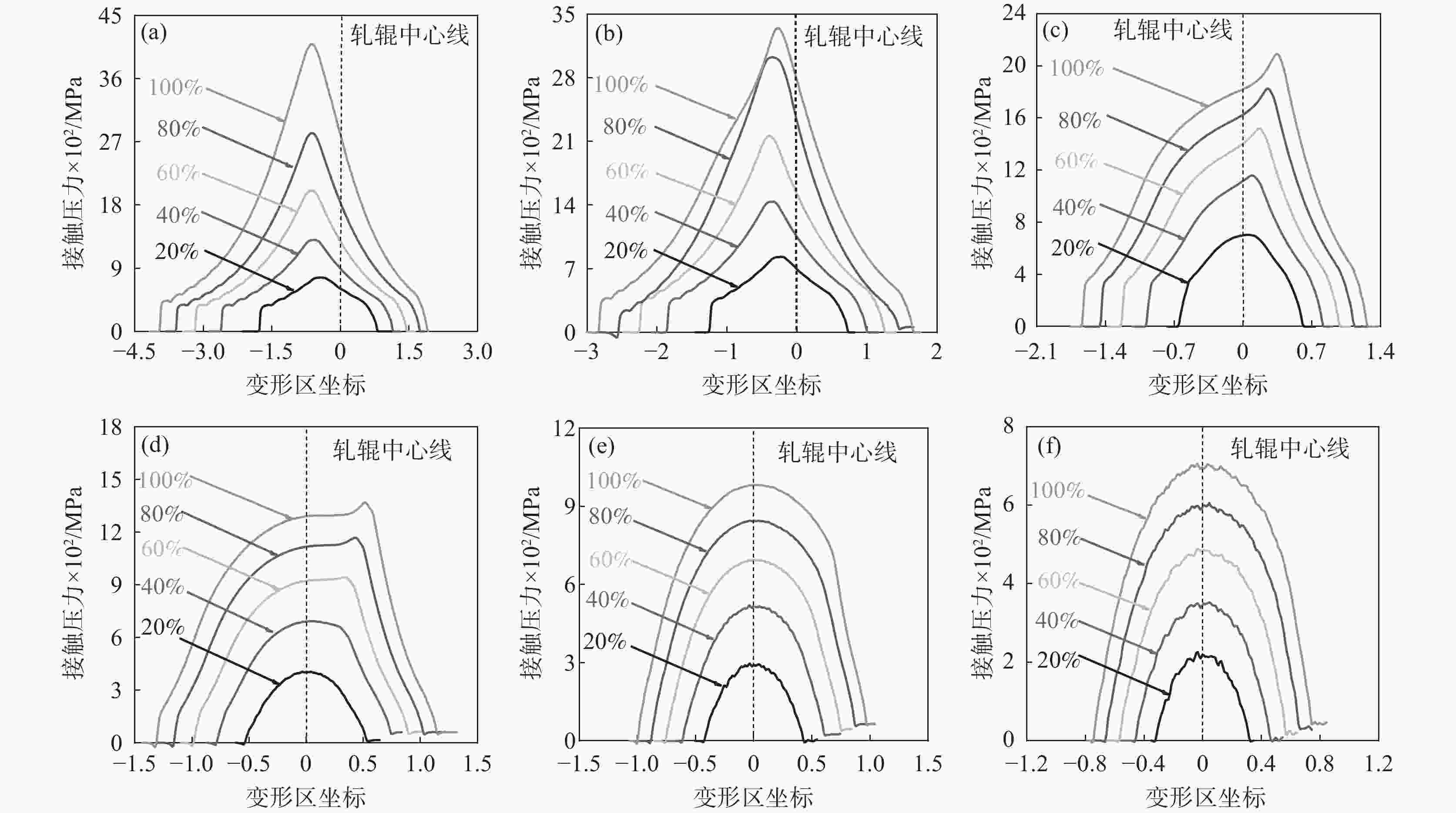

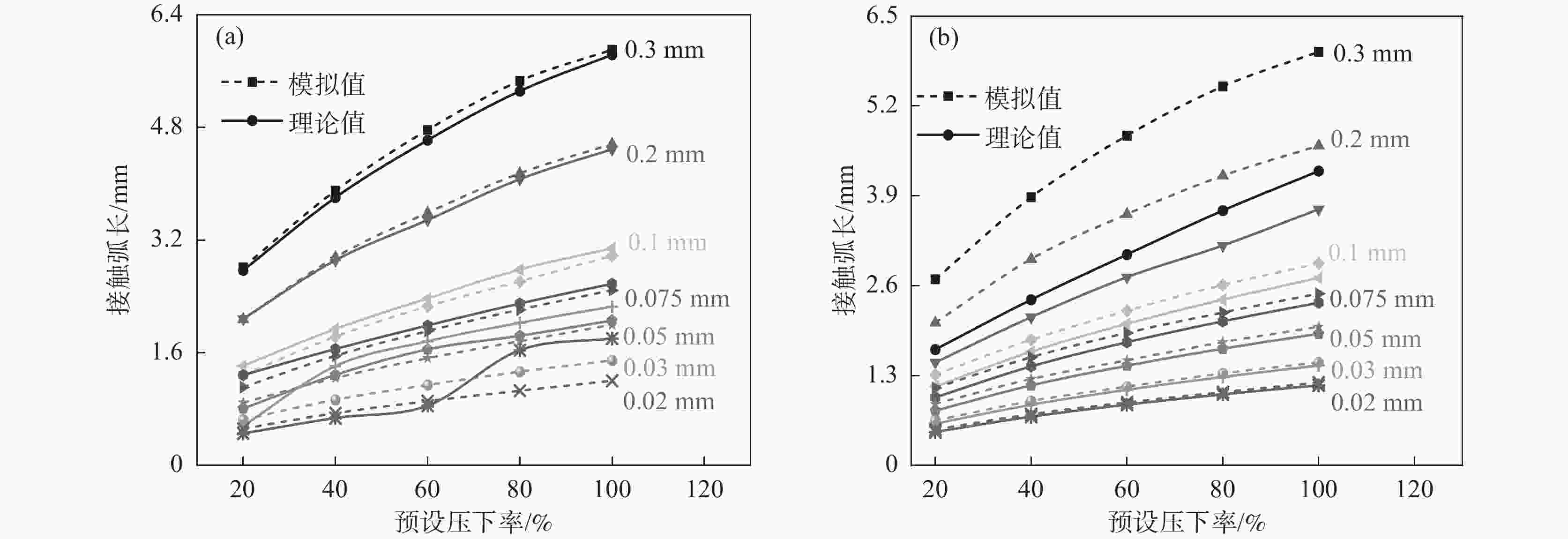

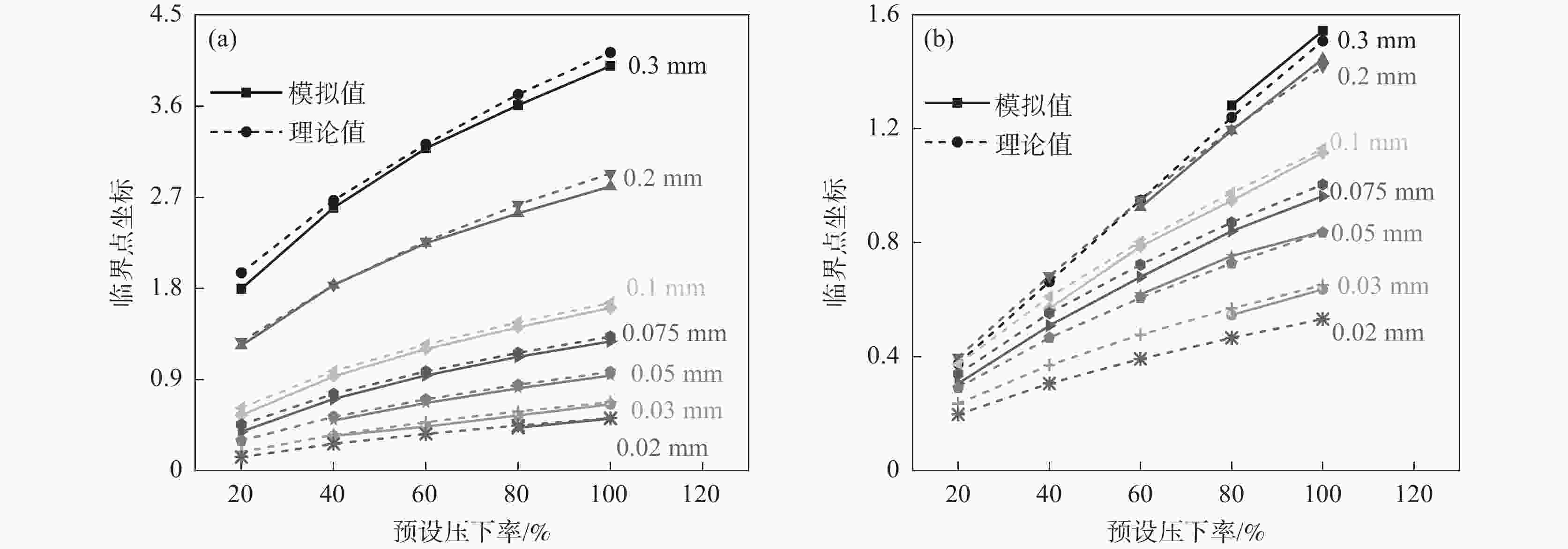

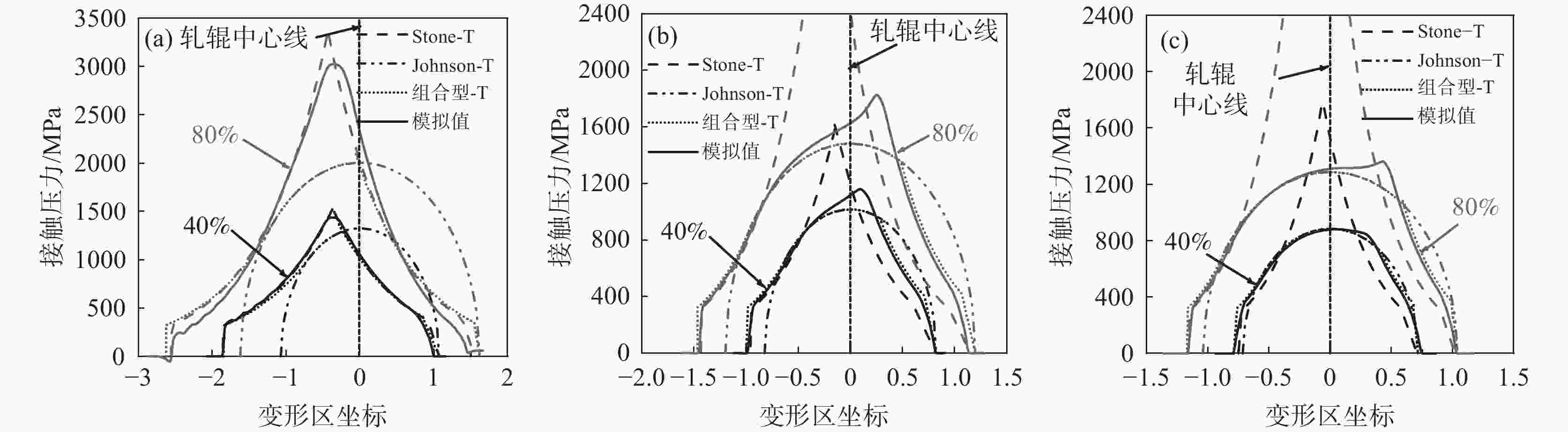

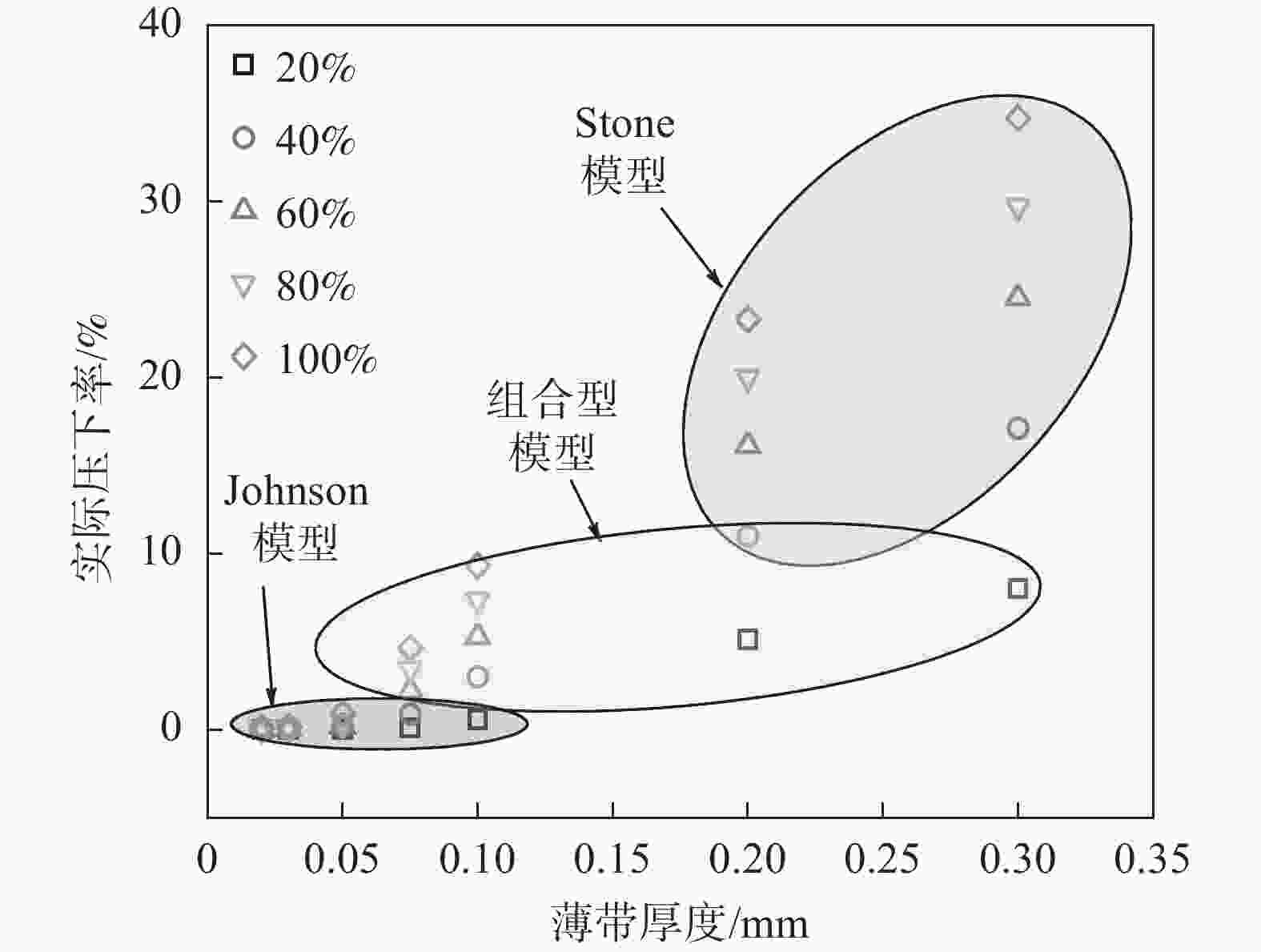

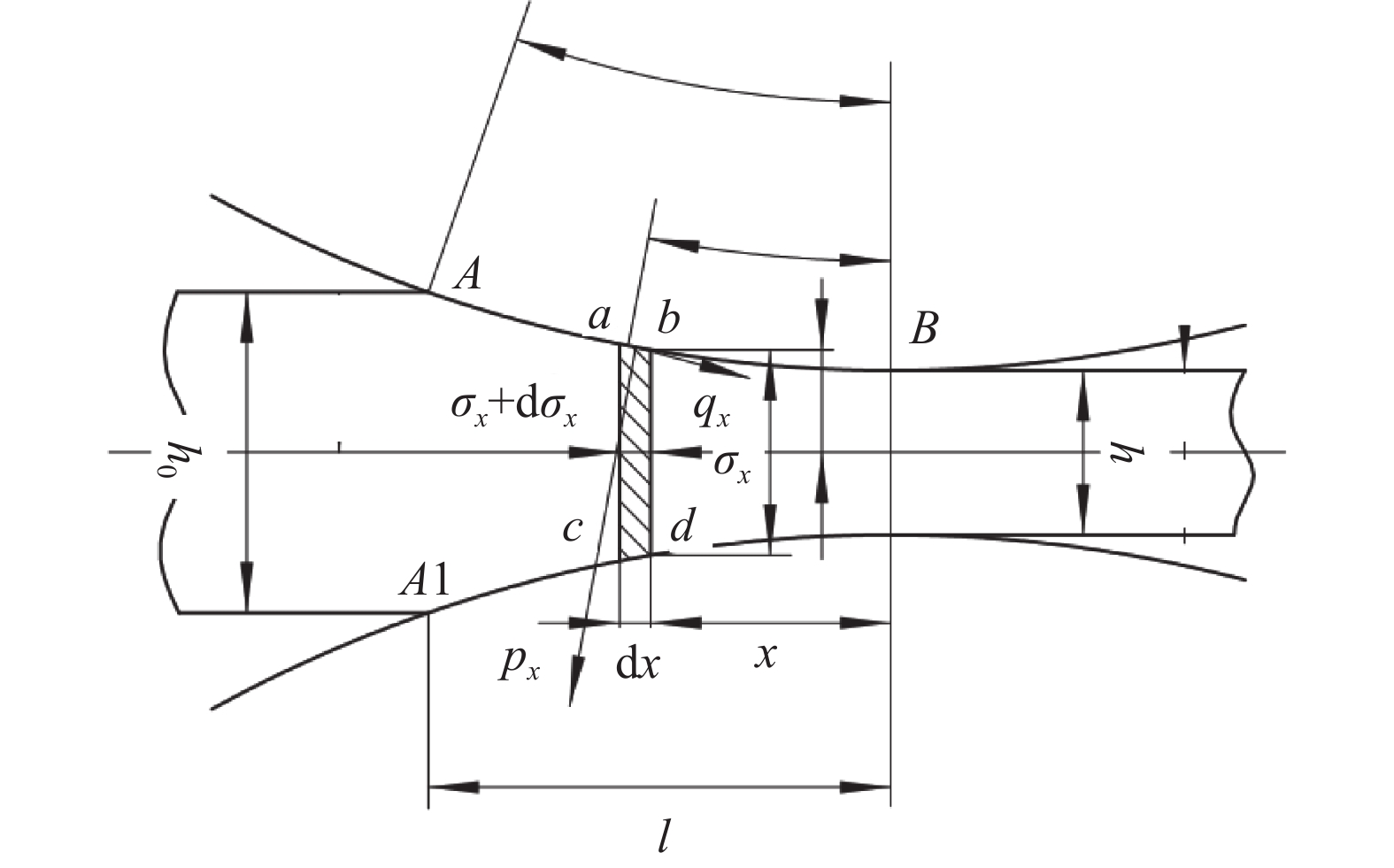

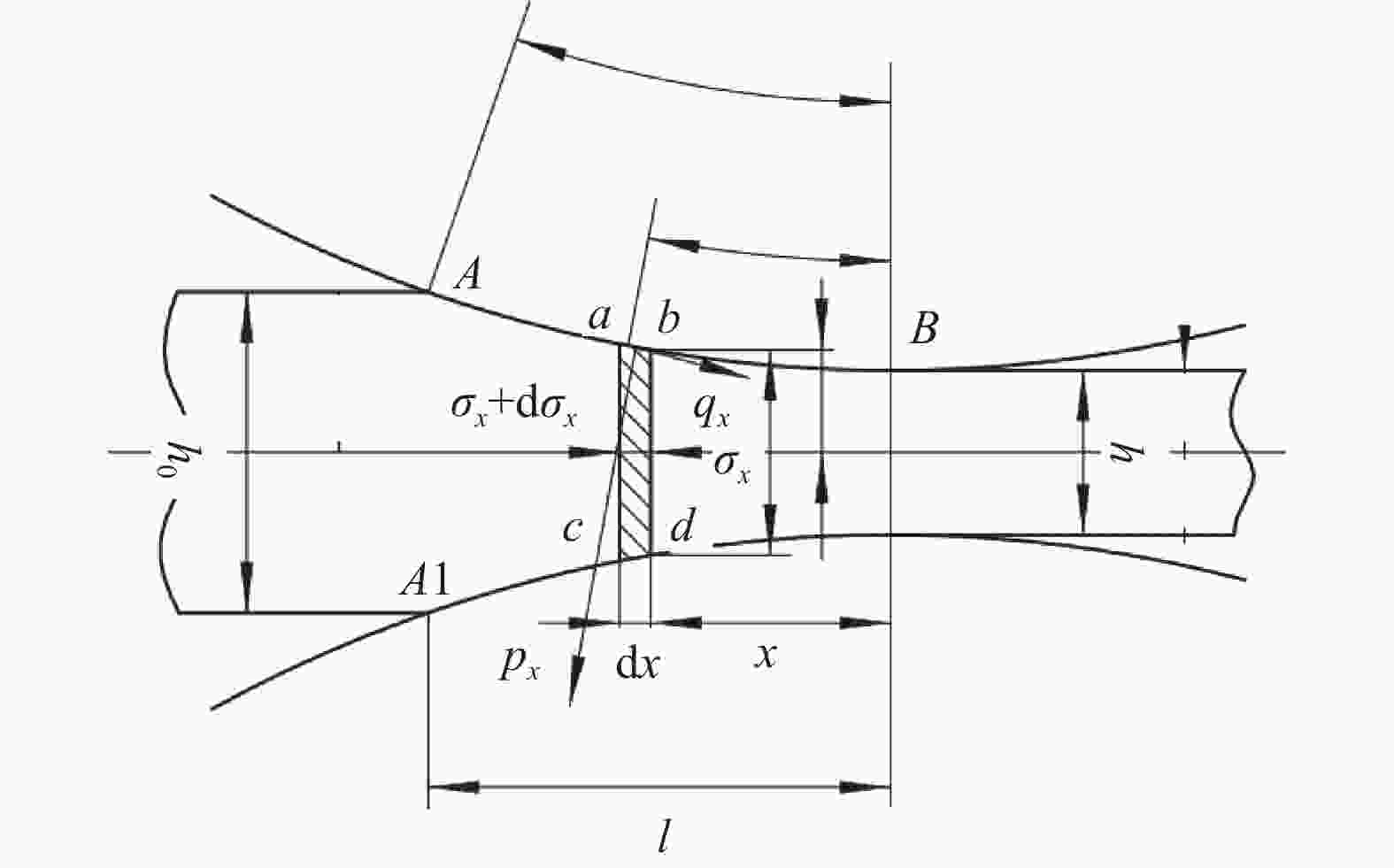

摘要: 薄带冷轧过程中轧辊会产生不同程度的弹性压扁现象,而各变形区理论对该现象认识的不同导致其计算精度和适用范围存在显著差异。为此采用有限元手段分析了薄带冷轧过程中变形区特征的变化规律,并对比探究了Stone全滑移、Johnson全弹性和组合型三种接触压力模型的推导特点、成立的先决条件和适用区间。结果表明:变形区轮廓随轧辊弹性压扁程度的加剧依次经历了圆弧形、圆弧压扁增大形、非圆弧形和近直线形,中性区的出现及其所占变形区比例的不断增加是导致实际压下率快减和变形区形状系数快增的主要原因。通过对比变形区接触压力曲线的模拟值与理论值可发现,Stone模型、Johnson模型和组合型模型分别适用于道次压下率大于10%、小于1%和1%~10%的轧制工况。Abstract: In the process of cold rolling of thin strip, the roll will produce different degrees of elastic flattening, and the different understandings of this phenomenon in each deformation in each deformation zone theory lead to significant difference in its calculation accuracy and application range. Therefore, the finite element method is used to analyze the variation law of the characteristics of the deformation zone in the process of cold rolling of thin strip, and the derivation characteristics, prerequisites and applicable intervals of the three contact pressure models of Stone total slip, Johnson full elasticity and combined type are compared and explored. The results show that with the increasing of the elastic flattening degree of the roll, the contour of the deformation zone undergoes arc shape, arc flattening enlargement, non-arc shape and nearly linear shape, and the occurrence of neutral zone and the increasing proportion of the deformation zone are the main reasons for the rapid decrease of the actual depression rate and the rapid increase of the shape coefficient of the deformation zone. By comparing the simulated and theoretical values of the contact pressure curve in the deformation zone, it can be found out that the Stone model, Johnson model and combined model are suitable for rolling conditions where the pass reduction ratio is greater than 10%, less than 1% and 1%~10%, respectively.

-

表 1 薄带轧制工艺参数

Table 1. Thin strip rolling process parameters

薄带初始厚度h0 /mm 预设压下率y/% 0.3、0.2、0.1、0.075、0.05、0.03、0.02 20、40、60、80、100 表 2 单位宽度轧制力模拟值与Johnson模型和组合模型理论值

Table 2. Rolling force per unit width from FE simulation and Johnson model & combined model

厚度/mm 预设压下率/% 模拟值/N 组合型理论值/N 组合型相对误差/% Stone理论值/N Stone相对误差/% 0.075 20 470.7 478.2 1.587 425.0 −9.717 40 995.0 1017.7 2.284 1082.6 8.808 60 1540.1 1554.0 0.905 2195.7 42.572 80 2105.7 2106.4 0.036 3649.7 73.326 100 2688.2 2674.3 −0.515 5629.7 109.424 0.1 20 632.5 645.0 1.975 552.2 −12.693 40 1313.7 1318.1 0.335 1284.0 −2.261 60 2036.2 2009.2 −1.326 2197.0 7.900 80 2790.9 2724.1 −2.394 4405.7 57.858 100 3572.0 3460.0 −3.136 5889.7 64.884 0.2 20 1077.3 1091.4 1.304 1068.5 −0.819 40 2231.0 2112.3 −5.318 2191.1 −1.787 60 3594.7 3273.2 −8.945 3690.6 2.666 80 5186.6 4561.5 −12.053 5203.1 0.318 100 6924.8 6011.9 −13.182 7627.7 10.151 -

[1] Mishra M K, Dubey V, Mishra P M, et al. MEMS technology: A review[J]. Journal of Engineering Research and Reports, 2019,4(1):1-24. [2] Fu M, Wang J, Korsunsky A M. A review of geometrical and microstructural size effects in micro-scale deformation processing of metallic alloy components[J]. International Journal of Machine Tools & Manufacture, 2016,109:94-125. [3] Xiao Hong, Ren Zhongkai, Liu Xiao, et al. Experiment and finite element simulation of roll flattening in deformation zone for ultra-thin strip rolling[J]. Iron and Steel, 2017,52(1):38-42. (肖宏, 任忠凯, 刘晓, 等. 极薄带轧制变形区轧辊压扁试验与有限元模拟[J]. 钢铁, 2017,52(1):38-42.Xiao Hong, Ren Zhongkai, Liu Xiao, et al. Experiment and finite element simulation of roll flattening in deformation zone for ultra-thin strip rolling[J]. Iron and Steel, 2017, 52(1): 38-42. [4] Liu Yaxing, Gu Qing, Zhang Wenjun, et al. Improved model for calculating rolling load of ultra-high strength steel in cold rolling process[J]. Iron and Steel, 2021,56(10):108. (刘亚星, 顾清, 张文军, 等. 超高强钢冷轧过程轧制力计算的改进模型[J]. 钢铁, 2021,56(10):108.Liu Yaxing, Gu Qing, Zhang Wenjun, et al. Improved model for calculating rolling load of ultra-high strength steel in cold rolling process[J]. Iron and Steel, 2021, 56(10): 108. [5] Karman T V. On the theory of rolling[J]. ZAMMZeitschrift fur Angewandte Mathematik und Mechanik, 1925,5:139-141. doi: 10.1002/zamm.19250050213 [6] Kuhn H A, Weinstein A S. Lateral distribution of pressure in thin strip rolling[J]. Journal of Engineering for Industry, 1970,5:453-459. [7] Kuhn H A, Weinstein A S. The minimum gauge problem in thin strip rolling[J]. Journal of Engineering for Industry, 1971,7:331-340. [8] Hitchcock J H. Roll neck bearings[R]. Report of ASME Special Research Committee. ASME, 1935: 33-41. [9] Stone M D. Rolling of thin strip part II[J]. Iron and Steel Engineer, 1956,33(12):55-76. [10] Wu Shoumin. Research of smallest permissive-rolling thickness during strip rolling[J]. China Metallurgy, 2007,17(3):10-12. (吴首民. 极薄带钢轧制过程中最小可轧厚度的研究[J]. 中国冶金, 2007,17(3):10-12. doi: 10.3969/j.issn.1006-9356.2007.03.003Wu Shoumin. Research of smallest permissive-rolling thickness during strip rolling[J]. China Metallurgy, 2007, 17(3): 10-12. doi: 10.3969/j.issn.1006-9356.2007.03.003 [11] Tateno J, Hiruta T, Katsura S, et al. Experimental analysis of thickness reduction limits in ultra-thin stainless steel foil rolling[J]. ISIJ International, 2011,51(5):788-792. doi: 10.2355/isijinternational.51.788 [12] Liu Xiao, Fu Lun, Lu Yuefeng, et al. Theory and numerical simulation of minimum rolling thickness for thin strip rolling[J]. Iron and Steel, 2021,56(11):87-95. (刘晓, 付伦, 芦跃峰, 等. 薄带材轧制的最小可轧厚度理论及数值模拟[J]. 钢铁, 2021,56(11):87-95.Liu Xiao, Fu Lun, Lu Yuefeng, et al. Theory and numerical simulation of minimum rolling thickness for thin strip rolling[J]. Iron and Steel, 2021, 56(11): 87-95. [13] Orowan E, Ing Dr. The calculation of roll pressure in hot and cold flat rolling[J]. Proceedings Institute of Mechanical Engineering, 1943,150(4):140-167. [14] Ford H, Ellis F, Bland D R. Cold rolling with strip tension[J]. Journal of the Iron and Steel Institute, 1951,168(1):57-72. [15] Ford H, Alexander J M. Simplified hot rolling calculations[J]. Institute Metals, 1959,88(6):193-197. [16] Bentall R H, Johnson K L. An elastic strip in plane rolling contact[J]. International Journal of Mechanical Science, 1968,10(8):637-663. doi: 10.1016/0020-7403(68)90070-2 [17] Johnson K L, Bentall R H. The onset of yield in the cold rolling of thin strip[J]. Journal of the Mechanics and Physics of Solids, 1969,17(4):253-264. doi: 10.1016/0022-5096(69)90015-5 [18] Fleck N A, Johnson K L. Towards a new theory of cold rolling thin foil[J]. International Journal of Mechanical Sciences, 1987,29(7):507-524. doi: 10.1016/0020-7403(87)90012-9 [19] Fleck N A, Johnson K L, Mear M E, et al. Cold rolling of foil[J]. Proceedings of The Institution of Mechanical Engineers Part B-Journal of Engineering Manufacture, 1992, 206(2): 119-131. [20] Xiao Hong, Liu Xiao. Theory and numerical simulation of gauge suitable to roll in ultra-thin strip rolling[J]. Iron and Steel, 2019,54(6):48-55. (肖宏, 刘晓. 极薄箔带轧制的适轧厚度理论及数值模拟[J]. 钢铁, 2019,54(6):48-55.Xiao Hong, Liu Xiao. Theory and numerical simulation of gauge suitable to roll in ultra-thin strip rolling[J]. Iron and Steel, 2019, 54(6): 48-55. [21] Xiao Hong, Ren Zhongkai, Liu Xiao. New mechanism describing the limiting producible thickness in ultra-thin strip rolling[J]. International Journal of Mechanical Sciences, 2017,133:788-793. doi: 10.1016/j.ijmecsci.2017.09.046 [22] Liu Xiao, Xiao Hong. Theoretical and experimental study on the producible rolling thickness in ultra-thin strip rolling[J]. Journal of Materials Processing Technology, 2020,278:116537. doi: 10.1016/j.jmatprotec.2019.116537 [23] Li Wei, Li Songsong, Yu Hui. Theoretical study on the limit rollable thickness of thin strip based upon rolling force[J/OL]. Engineering Mechanics,1-9[2024-12-02]. http://kns.cnki.net/kcms/detail/11.2595.o3.20230928.1640.014.html. (李伟, 李松松, 于辉. 基于轧制力判定的薄带材极限可轧厚度理论研究[J/OL]. 工程力学, 1-9[2024-12-02]. http://kns.cnki.net/kcms/detail/11.2595.o3.20230928.1640.014.html.Li Wei, Li Songsong, Yu Hui. Theoretical study on the limit rollable thickness of thin strip based upon rolling force[J/OL]. Engineering Mechanics,1-9[2024-12-02]. http://kns.cnki.net/kcms/detail/11.2595.o3.20230928.1640.014.html. [24] Li W, Li S S, Yu H. Research on the anisotropy of plastic behavior and deformation mechanism of textured pure titanium[J]. Materials Characterization, 2022, 194: 112483. [25] Li Wei, Yu Hui, Li Songsong, et al. Yield behavior of cold-rolled pure titanium thin strip based on anisotropy[J]. Rare Metal Materials and Engineering, 2023,52(9):3213-3220. (李伟, 于辉, 李松松, 等. 基于各向异性冷轧纯钛薄带的屈服行为研究[J]. 稀有金属材料与工程, 2023,52(9):3213-3220. doi: 10.12442/j.issn.1002-185X.20220739Li Wei, Yu Hui, Li Songsong, et al. Yield behavior of cold-rolled pure titanium thin strip based on anisotropy[J]. Rare Metal Materials and Engineering, 2023, 52(9): 3213-3220. doi: 10.12442/j.issn.1002-185X.20220739 -

下载:

下载: