Analysis of factors affecting the gloss of titanium dioxide in coatings

-

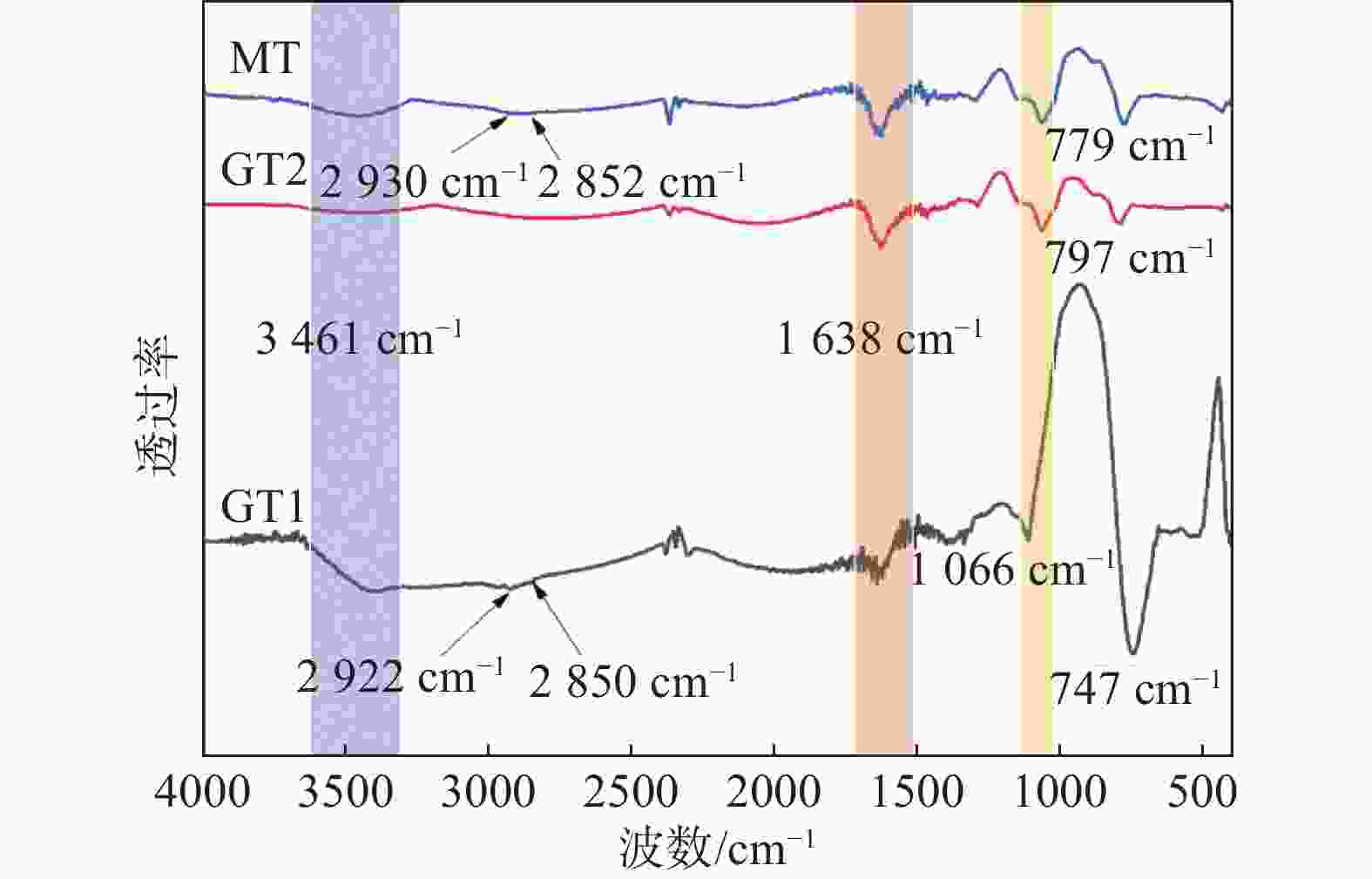

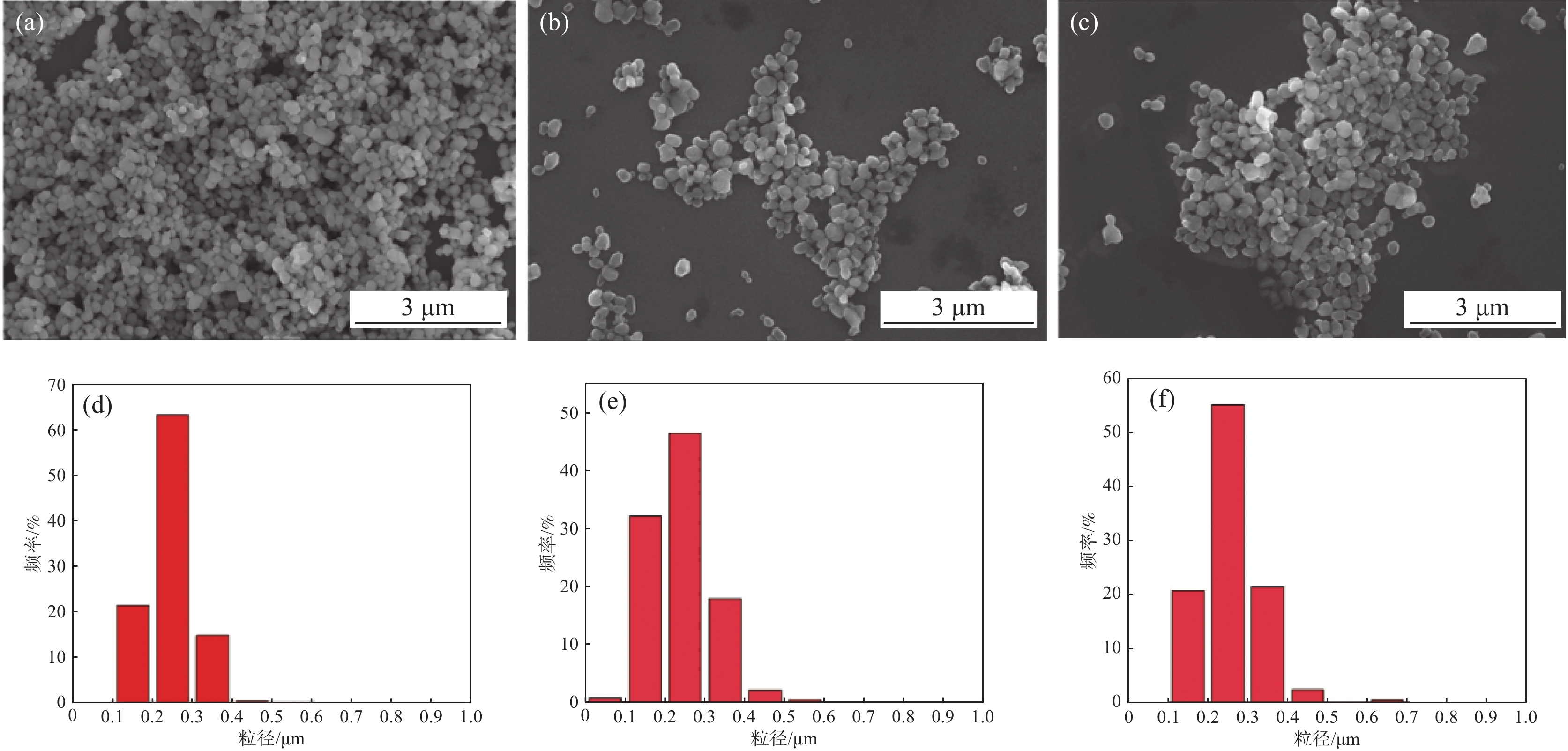

摘要: 针对国内外钛白粉在应用性能上的差异,采用SEM、TEM、EDS、XPS和FTIR等分析手段对不同钛白粉产品GT1,GT2和MT的微观结构进行表征,研究钛白粉在涂料中光泽度的影响因素。结果表明,MT粒径集中分布在0.1~0.5 μm,平均粒径为0.249 μm;表面包膜完整度高,包膜层厚度为1.2~4.5 nm;表面羟基含量较高,吸油量和比表面积低,在涂料中的分散性较好。正是因为国外钛白粉MT的表面结构优于GT1和GT2,从而使得MT在涂料中的光泽度高于国内钛白粉产品GT1和GT2。Abstract: Aiming at the differences in the application performance of titanium dioxide at home and abroad, the morphology of different titanium dioxide products including GT1, GT2 and MT were analyzed by SEM, TEM, EDS, XPS and FTIR. The influencing factors of the glossiness of titanium dioxide in coatings were studied. The results show that the MT particle size is centrally distributed in the range of 0.1-0.5 μm, with a mean particle size of 0.249 μm. The MT surface envelope has a high degree of integrity, with the thickness of the envelope layer ranging from 1.2 to 4.5 nm. The MT surface has a high hydroxyl content, with low oil absorption and specific surface area, and good dispersion in the coating. This is because the surface structure of foreign titanium dioxide MT is better than that of GT1 and GT2, so that the gloss of MT in coatings is higher than that of domestic titanium dioxide products GT1 and GT2.

-

Key words:

- titanium dioxide /

- surface composition /

- gloss /

- envelope integrity /

- particle size

-

表 1 不同钛白粉样品的表面氧物种

Table 1. Surface oxygen species of different titanium dioxide samples

样品名称 Ti-OH结合能/eV 表面羟基个数/(个·nm−2) GT1 530.77 2.37 GT2 530.39 3.00 MT 530.15 3.19 表 2 不同钛白粉比表面积和吸油量数据

Table 2. Specific surface area and oil absorption of different titanium dioxide

样品名称 比表面积/(m2·g−1) 100 g吸油量/g 分散性/μm GT1 15.5 19.1 11.7 GT2 13.9 19.0 18.3 MT 12.1 19.7 10 -

[1] Wei B X, Zhao L, Wang T J, et al. Photo-stability of TiO2 particles coated with several transition metal oxides and its measurement by rhodamine-B degradation[J]. Adv. Powder Technol, 2013,24(3):708−713. [2] Godnjavec J, Zabre J, Znoj B, et al. Investigation of surface modification of rutile TiO2 nanoparticles with SiO2/Al2O3 on the properties of polyacrylic composite coating[J]. Prog. Org. Coat, 2014,77(1):47−52. [3] Fotou G P, Kodas T T, Anderson B. Coating titania aerosol particles with ZrO2, Al2O3/ZrO2, and SiO2/ZrO2 in a gas-phase process[J]. Aerosol Sci. Tech, 2000,33(6):557−571. [4] Fu Zhengyan, Liang Yan. Effects of properties of titanium dioxide on the gloss of coatings[J]. Chemical Engineering Design Communications, 2022,48(6):43−45. (傅正彦, 梁艳. 钛白粉性能对涂膜光泽度的影响[J]. 化工设计通讯, 2022,48(6):43−45.Fu Zhengyan, Liang Yan. Effects of properties of titanium dioxide on the gloss of coatings[J]. Chemical Engineering Design Communications, 2022, 48(6): 43−45. [5] Godnjavec J, Zabret J, Znoj B, et al. Investigation of surface modification of rutile TiO2 nanoparticles with SiO2/Al2O3 on the properties of polyacrylic composite coating[J]. Progress in Organic Coatings, 2014,77(1):47−52. [6] Zhang Y, Yin Hengbo, Ren Min, et al. Deposition and characterization of binary Al2O3/SiO2 coating layers on the surfaces of rutile TiO2 and the pigmentary properties[J]. Applied Surface Science, 2010,257(4):1351−1360. doi: 10.1016/j.apsusc.2010.08.071 [7] Zhang Y, Yin H, Wang A , et al. Evolution of zirconia coating layer on rutile TiO2 surface and the pigmentary property[J]. J. Phys. Chem. Solids, 2010,71(10):1458−1466. [8] George J, Gopalakrishnan C C, Manikuttan P K, et al. Preparation of multi-purpose TiO2 pigment with improved properties for coating applications[J]. Powder Technology, 2021, 377: 269−273. [9] Ge C, Wang A, Yin H. Encapsulation of TiO2 particles with polystyrene and polymethyl acrylic acid and the pigmentary performances[J]. Journal of Industrial and Engineering Chemistry, 2012,18(4):1384−1390. doi: 10.1016/j.jiec.2012.01.043 [10] Yang Zhen, Wang Guilin, Li Haiyan, et al. The application and performance analysis on chloride-route titanium oxide coated with silicon, aluminum and zirconium[J]. Yunnan Metallurgy, 2017,46(6):43−47. (杨振, 王桂林, 李海艳, 等. 硅铝锆三元包膜氯化法钛白粉应用性能分析[J]. 云南冶金, 2017,46(6):43−47.Yang Zhen, Wang Guilin, Li Haiyan, et al. The application and performance analysis on chloride-route titanium oxide coated with silicon, aluminum and zirconium[J]. Yunnan Metallurgy, 2017, 46(6): 43−47. [11] Shao Guoxiong, Wu Tingting, Yan Yugang, et al. Production of titanium dioxide pigments with high gloss[J]. Coating Technology & Abstracts, 2016,37(7):43−46. (邵国雄, 吴婷婷, 晏育刚, 等. 提高涂料专用钛白粉光泽的技术现状研究[J]. 涂料技术与文摘, 2016,37(7):43−46.Shao Guoxiong, Wu Tingting, Yan Yugang, et al. Production of titanium dioxide pigments with high gloss[J]. Coating Technology & Abstracts, 2016,37(7): 43−46. [12] Peng Yi, Long Xiang, Li Haiyan, et al. The effect of chloridized titanium dioxide pigment volume concentration on application performance of acrylic acid coating[J]. Yunnan Metallurgy, 2017,46(4):54−57. (彭毅, 龙翔, 李海艳, 等. 氯化法钛白粉颜料体积浓度对丙烯酸涂料应用性能影响[J]. 云南冶金, 2017,46(4):54−57. doi: 10.3969/j.issn.1006-0308.2017.04.012Peng Yi, Long Xiang, Li Haiyan, et al. The effect of chloridized titanium dioxide pigment volume concentration on application performance of acrylic acid coating[J]. Yunnan Metallurgy, 2017, 46(4): 54−57. doi: 10.3969/j.issn.1006-0308.2017.04.012 [13] Shen L, Cao W, Wang A, et al. Preparation of TiO2@ZrO2@AlOOH@polymethyl acrylic acid nanocomposites and the impact of layer structure on color scheme, photocatalytic activity, and dispersion stability[J]. Industrial & Engineering Chemistry Research, 2020,59(50):21811−21821. [14] Cao W, Wang A, Yin H. Preparation of TiO2@ZrO2@SiO2@MAA nanocomposites and impact of layer structure on pigmentary performance[J]. Materials Chemistry and Physics, 2021,263:124403. doi: 10.1016/j.matchemphys.2021.124403 [15] Liu Y, Zhang Y, Ge C, et al. Evolution mechanism of alumina coating layer on rutile TiO2 powders and the pigmentary properties[J]. Applied Surface Science, 2009,255(16):7427−7433. [16] Li L, Wang L, Chen Xinhong, et al. The synthesis of bayberry-like mesoporous TiO2 microspheres by a kinetics-controlled method and their hydrophilic films[J]. Cryst. Eng. Comm., 2020,22(5):969−978. -

下载:

下载: